Australian solar thermal technology developer Vast Solar says it has put in an order for 13,500 sodium-ion batteries to form part of its proposed solar and storage facility at the Queensland mining centre of Mt Isa.

The deal with California-based Natron Energy will see Vast Solar use battery storage and solar PV for daytime power generation, while focusing the use of its concentrated solar thermal technology on night-time power needs.

The 50MW project, dubbed VS2, will deliver 24/7 power to Mt Isa, and help that city wean itself off its near total reliance on gas generation.

It will be built after Vast Solar completes its first project, the 30MW VS1 project which focuses on solar thermal only, at Port Augusta. That project, backed by up to $110 million in concessional finance once promised to the failed SolarReserve project, is due to come online in 2025.

Craig Wood, the CEO of Vast Solar, says Natron’s sodium-ion battery technology was chosen for its ultra long life, higher power density and fast recharge characteristics.

“It will enable us to maximise generation while sustaining baseload capacity and providing around-the-clock power,” Wood says.

The chances are that the two companies will work on other solar and storage projects. Vast says it has a strong pipeline of projects in Australia, the US, the Middle East, Europe and Latin America.

Solar thermal technology once held the promise of providing all solar and storage requirements, but it now focuses on picking out the best and cheapest additions from solar PV, and battery storage, while focusing the longer term thermal storage on night-time supplies.

Vast Solar’s technology differs from others in the CSP sector in that it combines elements from the two major forms of CSP: solar towers, and parabolic troughs.

Both technologies use mirrors to concentrate the sun’s rays and heat up a liquid – either oil or molten sodium – which is then used to heat water, creating steam which powers a turbine. Unlike solar PV, CSP can store energy in the molten salt, and provide power when the sun is not shining.

Vast Solar’s technology uses lots of small towers, rather than one big central tower, and uses the sun to directly heat molten sodium. Wood says this makes it much more efficient and allows the molten sodium to reach a higher temperature.

On the Port Augusta project, Vast is working with local Australian thermal storage hopeful 1414 Degrees, which has its own separate plans to pilot its silicon-based thermal energy storage technology SiBox.

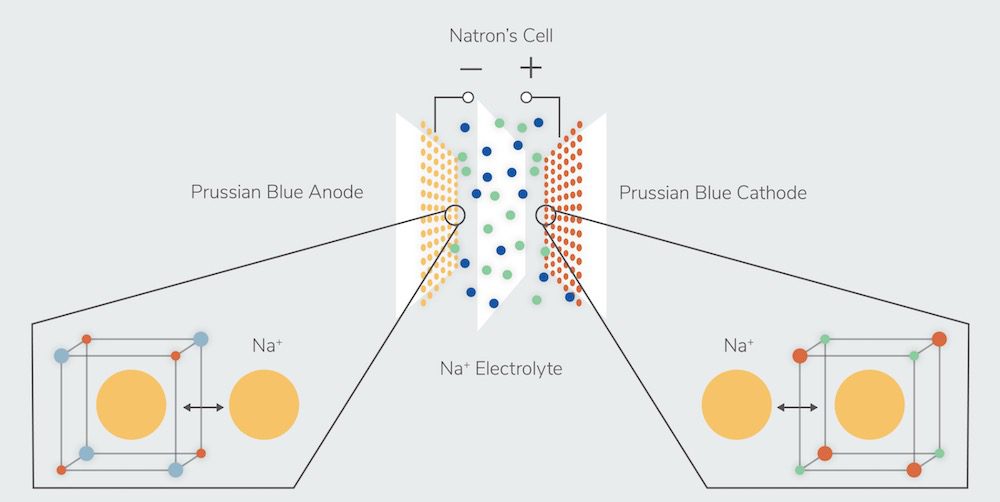

Natron’s batteries are based on a unique Prussian blue electrode chemistry that the company says offers higher power density, faster recharge, and significantly longer cycle life than incumbent technologies. They are also a safer chemistry than lithium-ion and avoid the use of difficult-to-obtain minerals like cobalt and nickel.

Natron aims to bring its sodium-ion batteries to mass production beginning in 2023 using an existing lithium-ion battery factory in Michigan, saving on time and cost of manufacture.

The company says its batteries’ unique chemistry is suited to a wide variety of industrial power applications ranging from critical backup power systems to EV fast charging and behind-the-meter applications.

Just last month United Airlines announced it was investing an undisclosed sum in Natron Energy, to help the carrier to safely electrify its airport ground equipment and operations at the gate.

A report published last week by Allied Market Research says the global sodium-ion battery industry is forecast to be worth $1.2 billion by 2031, up from $0.3 billion in 2021. It names Natron as one of the key players in the sector.

Vast Solar also plans to establish a “CSP gigafactory” to manufacture its heliostats and solar receivers on Australian soil, after a successful trial at a pilot plant in Goodna, Queensland.