An Australian start-up will deploy its innovative hydrogen-to-heat technology to produce industrial heat for food production which could potentially help decarbonise food manufacturing industries.

Star Scientific will pilot its thermal energy system, which can convert hydrogen into industrial heat, at Mars Food Australia’s New South Wales Central Coast operations.

The company’s HERO technology will be used to supply heat for the sanitation of food production operations, reducing Mars Australia’s use of gas in heat production, and will serve as the first real-world application of the technology.

“As a global company, we are committed to decarbonising our processes and working towards being ‘Sustainable in a Generation’, which includes investing in renewable energy and process heat,” Mars Food Australia general manager Bill League said.

“This pilot provides a real and tangible step towards a more sustainable future, and we are thrilled to be involved.”

Mars Australia produces a range of food and pet food brands, including the Masterfoods range and the Pedigree pet food range. In March, the company announced that it had transitioned to purchasing 100 per cent renewable electricity for its Australian offices and factories.

A spokesperson for Star Scientific confirmed that the partnership was “in advanced discussion with green hydrogen suppliers”, and it is hopeful the hydrogen supplied to the project will be from renewable sources.

The pilot project will form part of the Central Coast Hydrogen Food Cluster that will support the increased use of hydrogen in industrial-scale food operations, created through a partnership between Star Scientific and Central Coast Industry Connect.

“With the establishment of the Central Coast Hydrogen Food Cluster, we have the platform for industry players to be involved in the development of alternative heat sources for the food industry using hydrogen,” executive director of the Central Coast Industry Connect, Frank Sammut, said.

“Having a global company like Mars Food Australia taking part in this first pilot project demonstrates the will and the need of industry to move forward with becoming truly ‘Clean and Green’ and will showcase the enormous opportunity of this technology in the local and international marketplace.”

Star Scientific’s chairman Andrew Horvath said that the collaboration will serve as a key proof-of-concept example for the use of hydrogen in thermal heat applications and could eventually “pave the way” for renewable energy to displace the use of fossil gas in food production.

“We are really excited about being able to demonstrate how our HERO can pave the way for Australian food manufacturers to reduce emissions, and very grateful for the support from all levels of government for this pilot,” Horvath said.

“For us, it’s a recognition of the critical role that the cluster will play as an ‘incubator’ of regulatory issues for the hydrogen supply chain and more specifically, ‘green’ hydrogen made from renewable energy. This will enable us to identify challenges and provide solutions,”

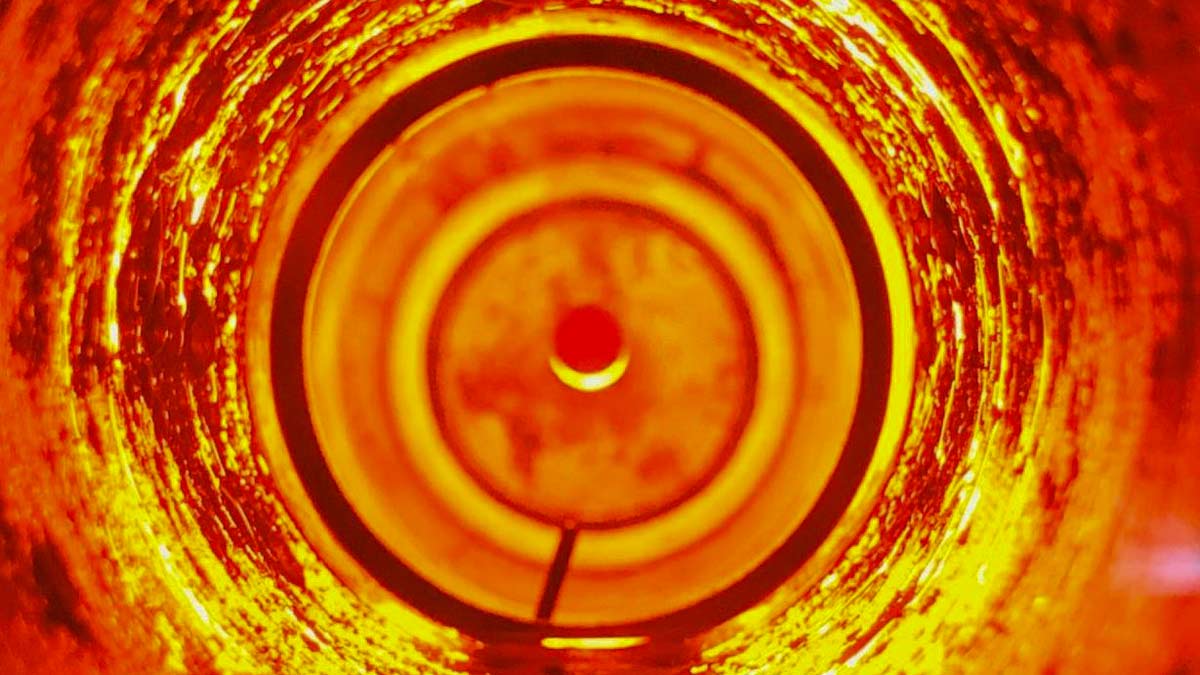

Based in Berkley Vale on the Central Coast, Star Scientific has developed an innovative new catalyst material, dubbed the Hydrogen Energy Release Optimiser, or HERO, which it says can convert hydrogen into heat without combustion, and at a very high thermal efficiency.

The HERO technology uses a secret catalyst material originally developed through its previous work in fusion energy technologies. The company says that it expects it to be deployed in power generation, energy storage, desalination, and industrial heat applications.

The company says the partnership with Mars Food Australia will enable it to test the technology in real-world conditions and provides an opportunity to address a range of regulatory requirements that would allow it to be deployed on a much broader scale for food production.

“Over the course of the past year, there has been a significant shift in the conversation around hydrogen with a new sense of urgency across industries. The global food manufacturing sector is demanding a green pathway to process heat for cooking and cleaning,” Horvath added.

“Our HERO technology answers the call; it is a non-polluting catalyst that uses hydrogen to generate zero emission, limitless heat necessary for many major industrial applications without any combustion.”

Lies, myths and greenwashing. Good independent journalism is time-consuming and costly. But small independent media sites like RenewEconomy have been excluded from the tens of millions of dollars being handed out to big media companies from the social media giants. To enable us to continue to hold government and business to account, to cut through the lies and the misinformation about the renewable transition, and to help expand our work, you can make a voluntary donation here to help ensure we can continue to offer the service free of charge and to as wide an audience as possible. Thank you for your support.