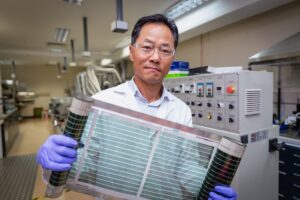

Solar experts from the University of New South Wales (UNSW) have called for “bespoke” technology designed to recycle solar panels, rather than the current wholesale shredding process which creates an additive for the production of bricks, concrete, or roadbase.

In an editorial published on Monday, two UNSW scientists highlighted the need for the principles of ‘Reduce, Reuse and Recycle’ to be applied to the end-of-life management of solar PV modules in Australia.

“We’ve seen a huge uptake in both small-scale and large-scale PV deployment in the last decade as the world moves towards renewable energy sources,” said Dr Richard Corkish from the Australian Centre for Advanced Photovoltaics, based at UNSW Sydney’s School of Photovoltaics and Renewable Energy Engineering.

“The industry standard for most solar panels’ lifespan is 25 to 30 years which means solar systems installed more than 15 years ago will soon be approaching their end-of-life.

“Additionally, in the last decade, we’re seeing a growing trend of replacing PV modules even though they are in perfect working condition.

“A lot of people installed small expensive systems some years ago but rather than adding on to them, they’ve been convinced to replace them altogether.”

These circumstances will quickly lead to an overabundance of end-of-life solar panels that need proper recycling.

Currently, the most common solar recycling process used in Australia is to put the panels through a standardised shredding machine where they are broken into smaller pieces that can be used as an additive in the production of construction bricks, concrete, or even roadbase.

But this method only ensures that end-of-life solar panels don’t end up in landfill and does nothing to reuse the rare materials used in the construction of solar panels.

According to Dr Rong Deng, research fellow from the UNSW School of Photovoltaics and Renewable Energy Engineering, the rare materials used are not being extracted while also keeping costs down.

“To be reused, solar panels components need to be carefully separated to avoid contamination with other materials,” she said. “Manufacturers will only reuse materials that have a high purity – which is difficult to achieve.

“The current process is a temporary solution. It’s great if all panels are recycled because we want to avoid it ending up in landfill. But if we think ahead, the materials we’re using right now are not always going to be readily available later.

“The silver embedded inside the cells is highly sought-after because of its value in pure form. However, the challenge we face is how we do that cheaply and without adding to our carbon footprint.

“If we continue down the path of using non-specialised technology to recycle PV modules,” Deng adds, “then we’ll …continue to end up with parts that are contaminated with other materials which is not a sustainable solution.”

This is particularly damaging if solar panels are being replaced well before their lifespan has actually run out.

Corkish says the photovoltaics research community is trying to lengthen the life of the modules by making them more resilient in the first place.

“The goal is to extend the life, so they last up to 50 years which means we won’t need to make nearly as many in the future,” he says.

“If we suddenly need to ramp manufacturing, we’ll find there are some materials, including silver and aluminium, that will be at risk of being in low supply.”

Deng says the federal government has also been considering adding PV modules to the Product Stewardship Scheme, which would require manufacturers to take responsibility for the full life cycle of solar.

“Similar schemes are already in place for other goods such as car tyres and plastic bottles,” she says.

Dr Corkish agrees, saying that if everyone who imports, designs, produces, sells, and uses PV modules has a shared responsibility for reducing their environmental impact, then it will further incentivise manufacturers to invest in better recycling technology.

“There needs to a system in place where costs are recouped from the industry so that cost imposed on new modules can pay for the recycling of the old ones,” says Corkish.

“The bottom line is that end-of-life PV systems will be a future environmental problem unless we address it now.”

European countries are already demonstrating the avenues by which better methods of recycling can be achieved, including using separation technologies, but Deng says this is partly because they have the motivation to do it.

“In Australia, we’re still waiting for the waste bomb that is predicted when all these PV modules come to the end-of-life, so there’s less incentive for local companies to invest in the technology.

“At some point, there will not be enough landfill to dispose of PV modules – nor will there be enough resources to build them. So, it’s imperative we find a sustainable solution to recycle them now.”