A world-leading storage plan for the mining city of Broken Hill – designed to create one of the world’s biggest renewable energy micro-grids – has been put under question because the technology provider has so far failed to get finance for a pilot project in South Australia, and has also laid off its sole Australian employee.

Hydrostor’s compressed air energy storage (CAES) technology was announced on Wednesday by transmission company Transgrid as its favoured option to replace ageing gas turbines that currently supply the emergency back-up in Broken Hill. It’s the largest CAES project of its type in the world.

Transgrid looked at a bunch of different options, including new transmission lines, and new gas generators, but decided that by far the best plan was for energy storage to support the existing 200MW Silverton wind farm and the 53MW Broken Hill solar farm, which are often unable to produce to capacity because of grid congestion, and cannot produce at all when the main link goes down.

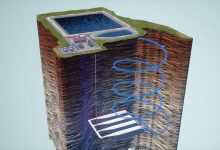

Transgrid looked at several different battery storage and demand response proposals, and decided that its preferred option was the Canadian-based Hydrostor’s Advanced CAES technology, which operates a bit like pumped hydro (but using heated and compressed air rather than water), and can deliver vast amounts of storage – in this case up to 200MW and up to 1,500MWh – enough to supply the town for days or even weeks.

Hydrostor in early 2019 was announced as a winner of $9 million in federal and state funding for a 5MW/10MWh pilot and demonstration project of its technology at the mothballed Angas zinc mine in South Australia. But it has been unable to access the $6 million in ARENA funding, and much of the $3 million state funding, because it has been unable to raise the rest of the $30 million needed for the project.

“We’re well invested to try and make it work, but Covid has presented challenges on the investment side,” the head of Hydrostor’s Australia operations Greg Allen told the local Strathalbyn newspaper, The Courier, last week.

Since then, however, Allen – the company’s sole employee in Australia – has been laid off (his LinkedIn profile says he is “open to offers”), and the company faces a revised and extended deadline of the end of the year to seal the finance and secure the funding from ARENA.

Hydrostor CEO Curtis VanWalleghem insists the company has not closed down its Australian operations, and has instead “restructured our approach” and will use consultants and local partners to advance its project opportunities in Australia. This includes renewable energy and storage project developer Energy Estate, which is behind the huge Walcha project in NSW and another 2000MW project in central Queensland.

“This has been partially driven by the challenges of cross-border travel with Covid, but also due to a lack of scale in Australia,” vanWalleghem told RenewEconomy via email. “We believe this new approach will best position our projects for success and allow Advanced-CAES to be more broadly deployed across Australia.”

Last September, Hydrostor announced it had landed $US37 million (then $A55 million) in funding but much of that money was destined for projects and operations elsewhere.

VanWalleghem says the Angas project is “shovel-ready” and the company is still working to finalize construction funding that has been delayed due to Covid. The timing remains uncertain but he says the much bigger Broken Hill project is not contingent on the Angas project.

“Angas is a small-scale project to demonstrate some new innovations and to help market the technology locally. We have the ability to underwrite scale projects such as Broken Hill,” he said.

CAES technology is not new, there are large projects in Germany and the US, but these mostly use gas turbines to deliver the power to compress and heat the air, which is then stored in caverns, before being released and re-heated and expanded to drive more turbines.

Hydrostor’s technology differs from the others in that it emissions free and uses a method known as hydrostatic compensation, where a head of water in the surface reservoir is used to maintain pressure.

Hydrostor’s technology differs from the others in that it emissions free and uses a method known as hydrostatic compensation, where a head of water in the surface reservoir is used to maintain pressure.

It’s widely used in the oil and gas industry, and putting the two together, with its proprietary thermal management system, is what Hydrostor wanted to demonstrate in Australia, as it has been doing in its small Goderich facility in Ontario.

ARENA has hailed the possibility of compressed air storage to deliver long-duration storage and much needed synchronous generation and grid security to support the renewables transition, as well as reviving the economy of local communities where mining operations have closed. (Mining caverns offer a great potential for compressed air storage).

“A-CAES combines well-established mining techniques with proven mechanical systems, representing a simple, bankable solution, which also has the ability to replace retired fossil plants, repurpose existing mining infrastructure, and defer the need for new transmission,” it says on its project page.

ARENA did not respond to questions from RenewEconomy about the status of the Angas project and its funding arrangement.