Researchers from California’s Stanford University say they have developed a new and ultrafast perovskite manufacturing process which is cheaper and four times faster than traditional manufacturing.

Solar PV cells today are mostly made with refined silicon, an energy intensive process, and for some time now researchers have been investigating the role that thin-film perovskites could have for the solar industry, a low-cost and more flexible solar cell that can be produced with minimal energy and virtually no carbon dioxide emissions.

Thin films of synthetic crystalline made from cheap and abundant chemicals like iodine, carbon, and lead, perovskite solar cells are lightweight, flexible and can be grown in open-air laboratories at temperatures near the boiling point of water. In comparison, refining industrial silicon requires 1,650-degree Celsius (3,000-degree Fahrenheit), a much more energy intensive process.

However, perovskite solar cells must overcome several challenges, not least, according to the researchers at Stanford University, is their inherent instability, which makes manufacturing them at scale difficult.

“Perovskite solar technology is at a crossroads between commercialization and flimflammery,” said Stanford University postdoctoral scholar Nick Rolston.

“Millions of dollars are being poured into startups. But I strongly believe that in the next three years, if there isn’t a breakthrough that extends cell lifetimes, that money will start to dry up.”

Rolston is part of a team at Stanford who have developed a new perovskite manufacturing process which they hope will yield an ultrafast way to produce stable perovskite cells and assemble them into solar modules that could power devices, buildings and even the electricity grid. The new perovskite manufacturing process was demonstrated in the journal Joule, in an article entitled “Rapid Open-Air Fabrication of Perovskite Solar Modules”.

“This work provides a new milestone for perovskite manufacturing,” said study senior author Reinhold Dauskardt, the Ruth G. and William K. Bowes Professor in the Stanford School of Engineering.

“It resolves some of the most formidable barriers to module-scale manufacturing that the community has been dealing with for years.”

While perovskite cells have been shown to be able to convert 25% of sunlight into electricity – a conversion efficiency similar to that of silicon-based cells – these experimental cells are incredibly small, and efforts to scale-up perovskite cells have resulted in defects and pinholes that significantly decrease cell efficiency. Further, unlike rigid silicon cells – which can last anywhere from 20 to 30 years – thin-film perovskite cells eventually degrade when exposed to heat and moisture.

“You can make a small demonstration device in the lab,” Dauskardt said. “But conventional perovskite processing isn’t scalable for fast, efficient manufacturing.”

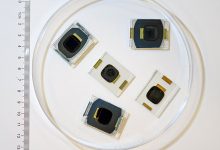

In an effort to address the issues with large-scale perovskite production, the Stanford research team invented and deployed a new technology called rapid-spray plasma processing, which uses a robotic device with two nozzles to quickly produce thin films of perovskite. One nozzle sprays a liquid solution of perovskite chemical precursors onto a pane of glass, while the other releases a burst of highly reactive ionized gas known as plasma.

“Conventional processing requires you to bake the perovskite solution for about half an hour,” Rolston said. “Our innovation is to use a plasma high-energy source to rapidly convert liquid perovskite into a thin-film solar cell in a single step.”

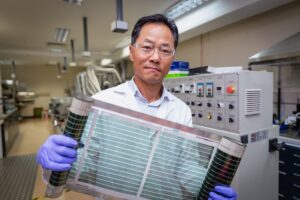

The new rapid-spray processing method allowed the Stanford team to produce 12-metres of perovskite film per minute – which is roughly four times faster than it takes to manufacture a silicon solar cell.

“We achieved the highest throughput of any solar technology,” Rolston said. “You can imagine large panels of glass placed on rollers and continuously producing layers of perovskite at speeds never accomplished before.”

Moreover, the new perovskite cells achieved a power conversion efficiency of 18%.

“We want to make this process as applicable and broadly useful as possible,” Rolston said. “A plasma treatment system might sound fancy, but it’s something you can buy commercially for a very reasonable cost.”

All in all, the Stanford research team believe perovskite modules manufactured using their new production method would cost about 25-US-cents per square foot – well below the $US2.50 per square foot needed to produce typical silicon modules.

The Stanford researchers also successfully created perovskite modules – combining perovskite solar cells in an encapsulated module that helps boost performance output and withstand harsh weather conditions – that continued to operate at 15.5% efficiency even after being left on the shelf for five months.

“If we can build a perovskite module that lasts 30 years, we could bring down the cost of electricity below 2 cents per kilowatt-hour,” Rolston said, as against the cost of 5-US-cents per kilowatt-hour currently achieved by conventional silicon solar modules.

“At that price, we could use perovskites for utility-scale energy production. For example, a 100-megawatt solar farm.”