One of the world’s biggest offshore wind developments has been halted because of spiralling costs, with Swedish state energy company Vattenfall on Thursday announcing suspension of the Norfolk Boreas project in the UK.

The 1.4GW project off the coast of Norfolk has been a major component of the UK’s renewable energy plans, and the decision to halt its development – because of a 40 per cent increase in costs and a spiralling cost of capital – could be a major blow to the viability of UK offshore wind.

“It simply doesn’t make sense to continue this project,” said Helene Bistrom, Vattenfall’s head of wind business in a briefing for the company’s latest results.

Earlier, CEO Anna Borg said the market for offshore wind power is challenging, despite unprecedented demand for fossil-free electricity.

“Higher inflation and capital costs are affecting the entire energy sector, but the geopolitical situation has made offshore wind and its supply chain particularly vulnerable,” she said in a statement.

Vattenfall says soaring costs were putting “significant pressure on all new offshore wind projects,” and that it would not “take an investment decision” immediately.

The company also says it will consider the best way forward for the rest of its UK plans, including the similar-sized Norfolk Vanguard projects, or a total of 4.2GW.

Vattenfall won a contract-for-difference for the project in a UK auction last year, guaranteeing a price of £37.35 (about AU$70) per megawatt hour (MWh) by 2012 prices – equating to around £45/MWh (about AU$85) today.

But the rising costs means it can no longer deliver on those targets. The wind industry is full of speculation that other projects may also struggle given the supply and cost issues that have emerged in the past 18 months.

The company says it will make losses of $536 million as a result of the decision.

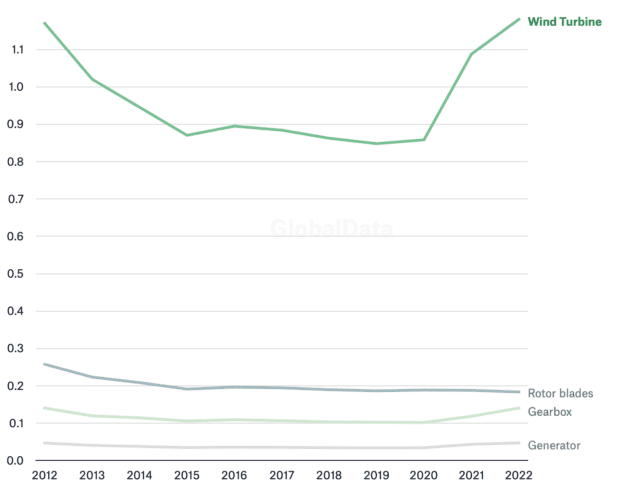

Though the cost of renewable energy has continued to trend downwards, the costs of manufacturing and assembling new wind farms has massively increased thanks to the chaos in global commodity markets. The cost of a wind turbine is now on average 38 per cent higher than it was two years ago.

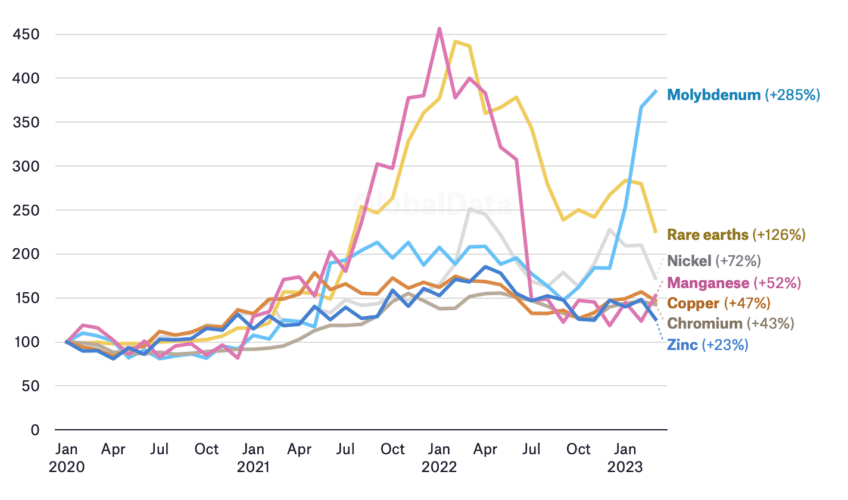

That’s partly because of supply chain problems and also because most of the metals needed to make a wind turbine, including copper, zinc, manganese, chromium, nickel, molybdenum and rare earths, have seen huge price hikes.

Vattenfall recently installed the last turbine in the 1.5GW Hollandse Kust Zuid offshore wind farm in the Netherlands, its largest project. Commissioning tests will be carried out in the coming months.

“Over the past decade, Vattenfall has built up its wind operations which today is a valuable and profitable business,” Borg said.

“We have attractive wind power projects in the pipeline, and investment decisions will always be based on profitability. We are convinced that offshore wind power is crucial for energy security and meeting the climate goals in Europe.”