Australian solar researchers have discovered that adding graphene to perovskite solar cells can improve efficiency to 30.6 per cent and cut the need for expensive gold and silver conductors.

The finding was part of manufacturing research between perovskite cell company Halocell Energy and the Queensland University of Technology (QUT), set up in 2023 to make the technology commercial.

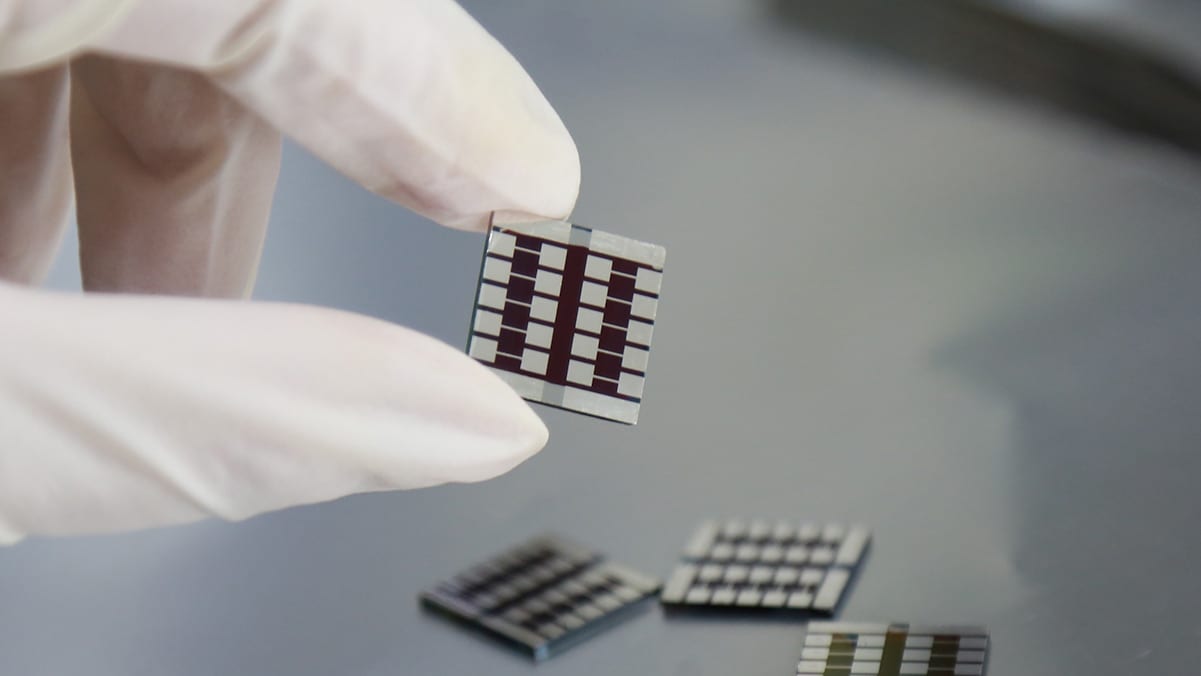

The latest finding suggests that adding a layer of graphene, a very light, highly conductive material made from graphite, to perovskite solar cells can be easily done using to roll-to-roll dispersion technology, a manufacturing method used to add extra layers to flexible substrates such as solar panels.

Halocell said the addition almost doubled the efficiency of the cell.

The addition of graphene means Halocell now has a “suite” of low cost materials for different solar applications, says Halocell Energy CEO Paul Moonie.

“This material will be included in sales of our Ambient PV range already available for purchase as well as our drone and satellite PV modules,” he said in a statement.

The company received a three year grant of $2.03 million from the federal Cooperative Research Centres Projects (CRC-P) to support the research with QUT.

In April, a team from QUT said they set a new efficiency record for the technology, and in July the university’s Dr Minh Tam Hoang from the School of Chemistry and Physics received a grant to work with Halocell on toxicity and instability of metal halide perovskite materials.

“Australia needs better fabrication processes for next-generation perovskite solar cells so we can increase market adoption of commercially viable technology with minimal risk in production,” he said in a statement at the time.

“By developing green-solvent solution processing – and PSCs based on tin instead of lead – this project will make real-world PSC manufacture cleaner and safer, delivering a new class of efficient, safe, stable, environmentally responsible solar cells.”

The perovskite family of solar materials has long been promising as a way to make light, flexible solar modules that are easily deposited onto different surfaces, as well as being cheap to produce and as efficient as silicon-based photovoltaic materials.

But a number of key hurdles have thus far blocked perovskite-based solar cells from becoming commercially competitive.

Among these is the time-intensive work of trying to nail down the right variations of the materials with the best efficiency, cost, and – most elusive of all – durability as they do not last as long as silicon.

But those hurdles are falling as companies such as California’s Caelux begin shipping perovskite glass, and Halocell says it’s been selling indoor cells in Australia for small electronics since last year.

Halocell is in the process of expanding a Wagga Wagga plant capacity by adding more roll-to-roll lines so it can hit a target of 60 million units a year.