The coal industry and some power utilities have been talking up the supposed benefits of ultra-supercritical power plants – leading some decision-makers and commentators to mistakenly believe that the choice of ultra-supercritical technology for a power plant will substantially mitigate air pollution and carbon dioxide emissions.

To understand the difference between subcritical, supercritical and ultra-supercritical power generation technology on the air pollutant emissions from a coal-fired power plant, the most important thing to know is this: which type of steam cycle is used has no impact on the emissions per tonne of coal burned.

Taking the example of sulphur dioxide (SO2) emissions, emissions per tonne of coal depend solely on the amount of sulphur contained in the coal, essentially all of which is oxidized into SO2 during combustion, ending up in the raw flue gas.

For example, for typical “low-sulphur” coal containing 0.5 per cent of sulphur when fed into the boiler, every tonne of coal will contain 5 kilograms of sulphur. When burnt, this sulphur turns into 10 kilograms (kg) of SO2. (Every sulphur atom joins with two oxygen atoms to produce one SO2 molecule which is twice as heavy as a sulphur atom.)

The only difference between different steam cycles in terms of emissions is how much power they can generate from one tonne of coal.

A typical new subcritical plant will have a thermal efficiency of 38 per cent, meaning that 38 per cent of the thermal energy contained in the fuel is converted into electrical energy fed into the grid.

A supercritical plant will have an efficiency of maybe 42 per cent and a typical ultra-supercritical plant will achieve around 44 per cent (designs going up to 47 per cent are being developed).

This means that a 1000 megawatt (MW) coal-fired plant using subcritical technology will need to burn coal at a thermal input rate of 1000 MW / 38 per cent = 2630 MW-thermal to generate its full output. This corresponds to 410 tonnes of coal per hour, assuming a typical calorific value of 5500kcal/kg, and 4100kg/h of SO2 in raw flue gas.

If the plant uses ultra-supercritical technology, it needs thermal input of 1000 MW / 44 per cent = 2270 MW-thermal. As a result, it burns 350 tonnes of coal per hour, or 14 per cent less than the subcritical plant and generates 14 per cent less SO2.

If the plant is not equipped with SO2 emission control technology, that’s the end of the story.

However, if the environmental regulators require the plant to meet SO2 emission limits that cannot be met without installing SO2 control devices, the plant will have to make additional investments.

Cleaning the air pollution

In essentially all countries except the US, SO2 emission limits are set in terms of SO2 concentrations in flue gas. The project developer will have to design a control device that removes enough of the SO2 from the flue gas to get below the limits.

Some of the toughest limits for SO2 emissions are found in China, where flue gases from coal-fired power plants are not allowed to contain more than 35 milligrams of SO2 for every cubic meter of dry flue gas.

The untreated flue gas from the example plants above will contain about 1200mg/m3 of SO2. Therefore, the plants will have to install SO2 control devices that remove about 97.5 per cent of the SO2 contained in untreated flue gas.

The difference between subcritical and ultra-supercritical technology is that the total amount of flue gas emitted from the ultra-supercritical plant is about 14 per cent smaller, and hence the capacity of the SO2 control device can be about 14 per cent lower, resulting in savings in investment and operating costs. Resulting SO2 emissions associated with a given emission standard will also be about 14 per cent lower.

The same logic applies to the emissions coal plant (NOx), particulate matter (PM), mercury and other heavy metals. The air quality and health impacts are directly proportional to emissions.

Moral of the story: Emissions regulation matters a lot, whether a plant is ultra-supercritical matters little.

So why are the coal industry and its advocates always going on about ultra-supercritical coal plants and not about emissions regulation?

Simple: ultra-supercritical plants are usually more profitable than subcritical plants, since they have lower fuel and other operating costs.

Stringent emission regulation, in contrast, increases both investment and operating costs. I hope you’re not too shocked that coal advocates are not mainly motivated by health concerns.

It is worth noting that Australia, the main peddler of “High Efficiency Low Emissions” (HELE) coal plants along with Japan, hasn’t even required flue gas desulphurisation equipment on its own coal plants, making them some of the dirtiest in the world.

Below is a simple graph illustrating the effect of emissions regulation versus type of steam cycle on SO2 emissions:

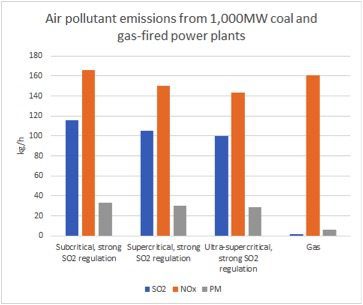

The chart below shows a comparison between coal and gas plants following the same Chinese emission standard.

SO2 and particle emissions from gas are a tiny fraction of those from coal, while NOx emissions are similar. It would be technically easy for the gas plant to go a lot lower but this is what current standards require.

Lauri Myllyvirta works for Greenpeace East Asia.