Australian researchers have helped achieve a breakthrough in the production of flexible and efficient solar power materials, which could provide a pathway to wearable solar power.

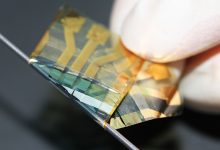

The research has been detailed in a pair of papers published in the academic journals Joule and PNAS. The researchers outlined a way of producing ultra-light weight and flexible solar cells, that could be integrated into clothing or directly into the surfaces of electronic devices.

The researchers used a new generation of organic solar cells that provide a high degree of flexibility while achieving solar conversion efficiencies of up to 13 per cent, opening up the potential for the production of practical solar integrated materials.

Not only are the innovative organic solar cell designs developed by the researchers capable of being integrated into light-weight and flexible materials, including clothing, but they are also able to achieve some of the highest conversion efficiencies seen amongst organic solar cells.

“Power conversion efficiency considers how much solar energy can be converted into electricity. The solar energy illuminated on Earth is 1000 watts per square metre. Our device can produce 130 watts of electricity per square metre. The 13 per cent efficiency we were able to achieve is one of the highest efficiencies in organic solar cells,” Monash University research fellow Dr Wenchao Huang said.

“Our ultra-flexible solar cells can simultaneously achieve an improved power conversion efficiency, excellent mechanical properties and robust stability. This makes them a very promising candidate as a power source in wearable electronics to realise long-term monitoring of various physiological signals, such as heart and breathing rates.”

The research was led by Japanese scientific institution RIKEN, which collaborated with both the Australian Synchrotron and Monash University, as well as the Universities of Tokyo and California.

The researchers were able to demonstrate just how light-weight the solar cells could be, producing a 2cm squared solar cell, that was light enough to be supported by a flower petal while producing almost 10 watts of power.

Such a light-weight and flexible solar cell could find application in consumer electronics, such as smartwatches or mobile phones.

The researchers said that the production method used to produced the flexible organic solar cells used a continuous printing technology, making it suitable for use in mass produced wearable technology.

Using an innovative annealing technique, that involves a heat treating process applied to materials, the researchers were able to significantly improve the resistance of the flexible solar cells to degradation.

Based on the stress testing completed as part of the research project, the flexible solar materials were able to maintain 97 per cent of their output efficiency even after 1,000 cycles of bending tests.

After a 1,000 cycle stretching test, the solar cells retained almost 90 per cent of their performance.

The researchers said that this could mean that the solar panels could continue to operate for at least two and a half years without significant degradation, and had an estimated “shelf life” of more than 11 years.

Traditional solar cells are manufactured using silicon wafers that are both very stiff and very brittle, making them unsuitable for use in any flexible materials.

However, as organic solar cells are manufactured using polymers or small molecules that work as semiconductors, they are able to work while being significantly more flexible.

“Currently, silicon solar cells are the dominant technology in the photovoltaic market, which are commonly found in rooftop installations. But, their brittle nature means solar cells exhibit poor performance when bent or stretched,” Dr Huang said.

“Here, we have developed an ultra-flexible organic solar cell with a total thickness of just three micrometres – one of the thinnest solar cells in the world.”

The next steps for the researchers are to work towards the commercialisation of the flexible solar cells.

Last week, researchers from Monash University unveiled new techniques for identifying and eliminating flaws in next-generation perovskite solar cells using a ‘trick of the light’ to reveal flaws that cannot be seen by the naked eye.

RenewEconomy and its sister sites One Step Off The Grid and The Driven will continue to publish throughout the Covid-19 crisis, posting good news about technology and project development, and holding government, regulators and business to account. But as the conference market evaporates, and some advertisers pull in their budgets, readers can help by making a voluntary donation here to help ensure we can continue to offer the service free of charge and to as wide an audience as possible. Thankyou for your support.