A new lithium-sulphur battery design from Australian researchers could slash the quantity of lithium needed in a battery by half, and eliminate one of the key flaws in the battery chemistry.

Researchers at Monash University say they made major advances in the development of lithium-sulphur batteries, which are emerging as a popular chemistry because they can store at least double the amount of energy per unit weight (Wh/kg) compared to lithium ion batteries.

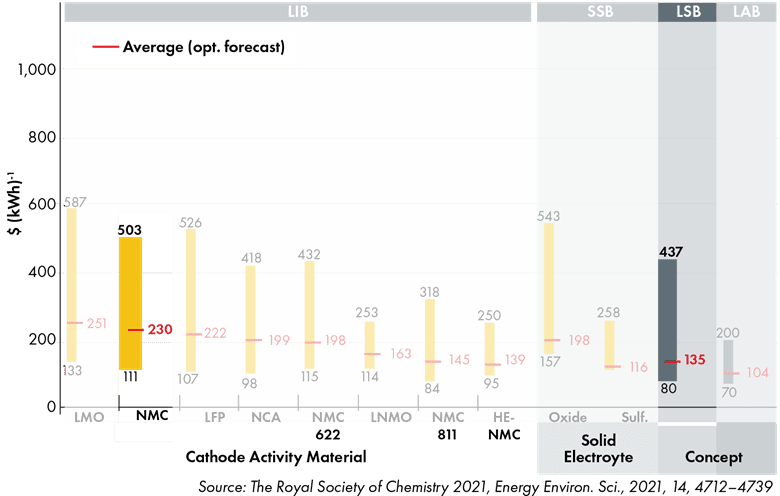

Sulphur is also very common, easy to obtain, and cheap, compared to lithium which also comes with political issues around its provenance. This battery chemistry doesn’t need any nickel or cobalt either.

But early lithium-sulphur batteries didn’t perform well because sulphur from the positively-charged cathode would dissolve into the electrolyte and attack the lithium anode. This rapid decay quickly reduced the number of times a battery could charge and discharge.

The solution is to protect the anode with a barrier – an idea that has also been divined by researchers at the Argonne National Laboratory in the US, who created a layer between the cathode and anode to prevent reactive sulphur species from reaching the negative electrode.

The researchers at Monash say they have coated a lithium foil anode with a nanoporous polymer, which they say allows lithium ions to move through while protecting the anode from corrosive sulphur compounds.

“Lithium-sulphur batteries replace expensive metals such as cobalt and nickel in their cathode with widely available waste product sulphur, which reduces the cost massively,” corresponding author and Monash University Professor Matthew Hill told RenewEconomy.

“In this discovery, we’ve further lowered the amount of lithium needed, by half, which helps even more in lowering the cost.

“We were able to cycle this battery around 300 times with quite stable performance. Because lithium-sulphur batteries store twice the energy, fewer cycles are also needed to keep up with their counterparts. We have gotten to over a thousand cycles now in some lithium-sulphur battery examples.”

Declan McNamara, PhD student and lead author on the paper outlining the findings, said the thin polymer coating contains tiny holes less than a nanometre in size which allow lithium ions to move freely while acting as a scaffold for lithium to intercalate into the anode (when ions are inserted into the host – anode – matrix).

“Metallic lithium is a bit of a double-edged sword. Lithium is packed full of energy, but in a bad battery, this energy is wasted on side reactions,” McNamara says.

“On the other hand, if the energy is channelled correctly, it can make some incredible energy storage devices that are easier to make.”