A common dietary supplement could be the key to producing low cost and environmentally friendly next-generation solar cells, with Australian researchers achieving a new efficiency milestone for perovskite solar cells.

The research has been published in the journal Cell Reports Physical Science, and provides a potential pathway to lower-cost next-generation solar panels, using materials that are less toxic for the environment.

The researchers, based at the University of Sydney, said they had made crucial improvements process of ‘gas quenching’ to fabricate perovskite thin films, a key component of the next-generation solar cells.

The research team, said that they had successfully demonstrated a steady-state conversion efficiency of 23.6 per cent, which they claim is the highest efficiency achieved for perovskite solar cells produced using the ‘gas quenching’ technique.

“This is significant for low solvent (therefore, lower cost and reduced toxicity) and scalable manufacturing of efficient [perovskite solar cells],” the research paper says.

Current manufacturing techniques rely on the use of “anti-solvent” in the production of perovskite solar cells. These anti-solvents can both increase the cost of solar cell manufacturing perovskite solar cells, as well as ultimately being toxic to the environment.

By eliminating the use of the anti-solvents, while maintaining similar levels of performance, the is the potential to produce lower cost and environmentally friendly next-generation solar cells.

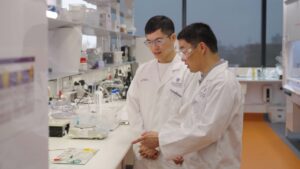

“Many high-performance perovskite solar cells are fabricated using ‘anti-solvents’, to assist in the formation of good-quality multi-crystalline perovskite film. However, many of these solvents are toxic,” University of Sydney PhD student and lead author Shi Tang said.

“We use gas quenching of the perovskite surface to achieve the same outcome. This reduces the amount of solvent used. Also, unlike anti-solvent treatment, gas quenching is compatible with other methods that are critical for large-scale manufacturing.

“In our work, we have developed methods that are compatible with gas-quenched-deposition for passifying defects at the surface of the film and within the bulk of the perovskite layer. This allows us to achieve a very high energy conversion efficiency,” Tang added.

The researchers said that they had made improvements to the production processes that use the ‘gas quenching’ technique, setting a new milestone for the conversion efficiency the cells can demonstrate over an extended period, and using a method that can be applied in other production processes to achieve similar performance improvements.

Key to this, the paper says, was the use of potassium iodide in precursor materials, which improved the quality of thin films and their performance in the solar cells. Potassium iodide is commonly used as a dietary supplement, found in iodise salt to prevent iodine deficiency.

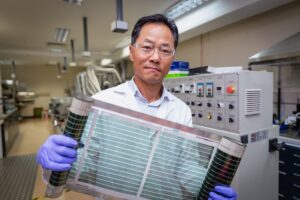

Perovskite solar cells have attracted significant interest from researchers, showing promise as the next generation of solar cells, with the potential to be produced at a lower cost and more flexibly than conventional silicon-based solar cells.

While researchers have been able to demonstrate conversion efficiencies for perovskite solar cells that are on par with silicon-based solar cells, ongoing research has focused on improving their long-term durability, which is currently insufficient for wide-scale commercial applications.

However, unlike traditional solar cells produced using silicon wafers, perovskite solar cells have the potential to be incorporated directly into flexible structures and shaped directly onto the surface of structures like buildings or even electric vehicles.

“Our next step is to apply these discoveries for large area cells, for perovskite-tandems. Cells of this kind are also used for testing new techniques being developed in our lab to improve cells’ durability, following on our work from last year that was published in Science,” corresponding-author and research team leader professor Anita Ho-Baillie said

A number of leading Australian research institutions, including those at the University of Sydney, the Australian National University and the University of New South Wales have led global research efforts in the development of perovskite solar cells, achieving several efficiency and durability milestones.

The latest research was completed with support from the Australian Research Council, the CSIRO and the Australian Renewable Energy Agency.