Australian researchers have revealed the secret to a record-breaking perovskite solar cell design in a new paper, saying that poking holes in poorly conducting materials was key to improving performance.

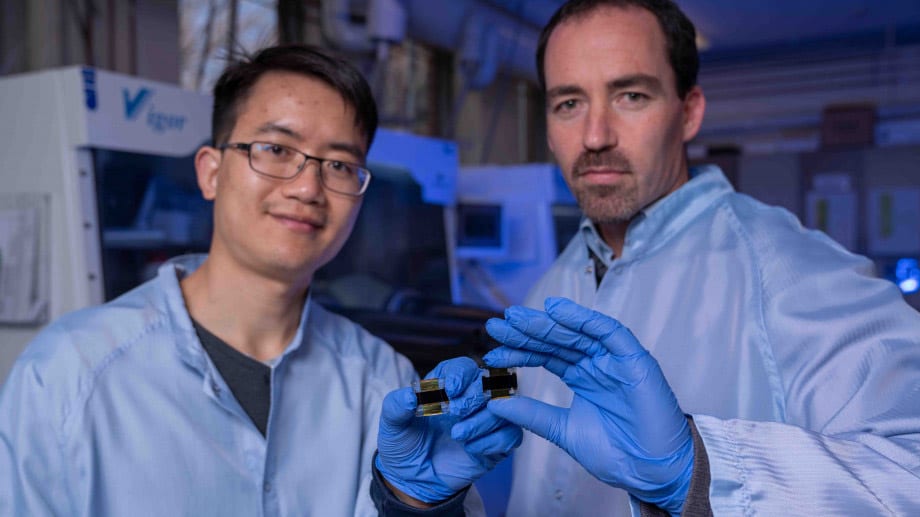

The research team, based at the Australian National University, achieved a conversion efficiency world record for next generation perovskite solar cells, the amount of solar energy converted into useful electricity, of 21.6 per cent.

The record was first reported August last year, but the details of the results, and the techniques used by the research team to achieve them, have now been published in the journal Science.

Lead researcher, associate professor Tom White, said the research team achieved the new record by adapting a technique previously used with traditional silicon-based solar cells that removed defects.

“A common problem with solar cells is that any defects in the cell can trap electrons, taking away the energy they gained by absorbing sunlight,” associate professor White said.

“A way around this is to “passivate” the surface by coating the light absorbing material with a thin layer of another material to reduce defects. But the materials used to reduce defects are often poor conductors of electricity.”

Researcher Dr Jun Peng said that the common solution to the challenges caused by the poor conducting materials was to produce holes in the coatings to allow electricity to pass through.

The researchers used nanoscale rods, made from titanium oxide, that enabled electrons to be transported through the poorly conducting material, optimising performance with the need to avoid defects.

“Some silicon cells use holes to let the electrons through this insulating layer, creating a kind of conductive pathway. We decided to take a similar approach with our perovskite cells,” Dr Peng said.

“The idea behind it and the reasons it works are the same, but our models showed us that to make it work on perovskite solar cells, we would need to manufacture these holes on the scale of nanometres – thousands of times smaller than is used in silicon.”

“Thus, instead of holes, we used nanoscale rods that poke through the insulating layer.”

Before producing a working solar cell based on the new approach, the research team first used computer modelling to prove that the concept would work.

“Computer models are really useful in a study like this,” the project’s modelling lead, Dr Daniel Walter, said.

“Once you have made a solar cell it can be difficult to probe inside them to see what is happening. We were able to simulate what was happening inside the cells to explain how the nanorods improved the cell performance.”

The researchers said that they would continue to work on improving the efficiencies of perovskite solar cells.

One of the main barriers to the commercialisation of perovskite solar cells, which show promise as a cheaper and more adaptable alternative to silicon solar cells, is longevity.

The semiconductor materials used to produced perovskite solar cells are prone to degradation. In their paper, the ANU researchers said their record-breaking perovskite solar cells were able to maintain almost 92 per cent of their initial efficiency after 1000 hours of damp heat exposure.

Last year, another group of researchers at the Australian National University set a new performance record for tandem solar cells, where perovskite solar cells are layered on top of traditional silicon solar cells to achieve a higher combined efficiency as each layer draws upon different parts of the solar spectrum.