Queensland researchers have developed new all-in-one chemical processes that could provide a pathway to carbon storage, green hydrogen production and the creation of materials needed by the construction industry, detailing a proof-of-concept demonstration in a new research paper.

The research, undertaken by scientists at the Queensland University of Technology, has been published in the journal ChemSusChem, detailing a chemical process that provides the potential for carbon storage and the production of both green hydrogen and key inputs into cement manufacture.

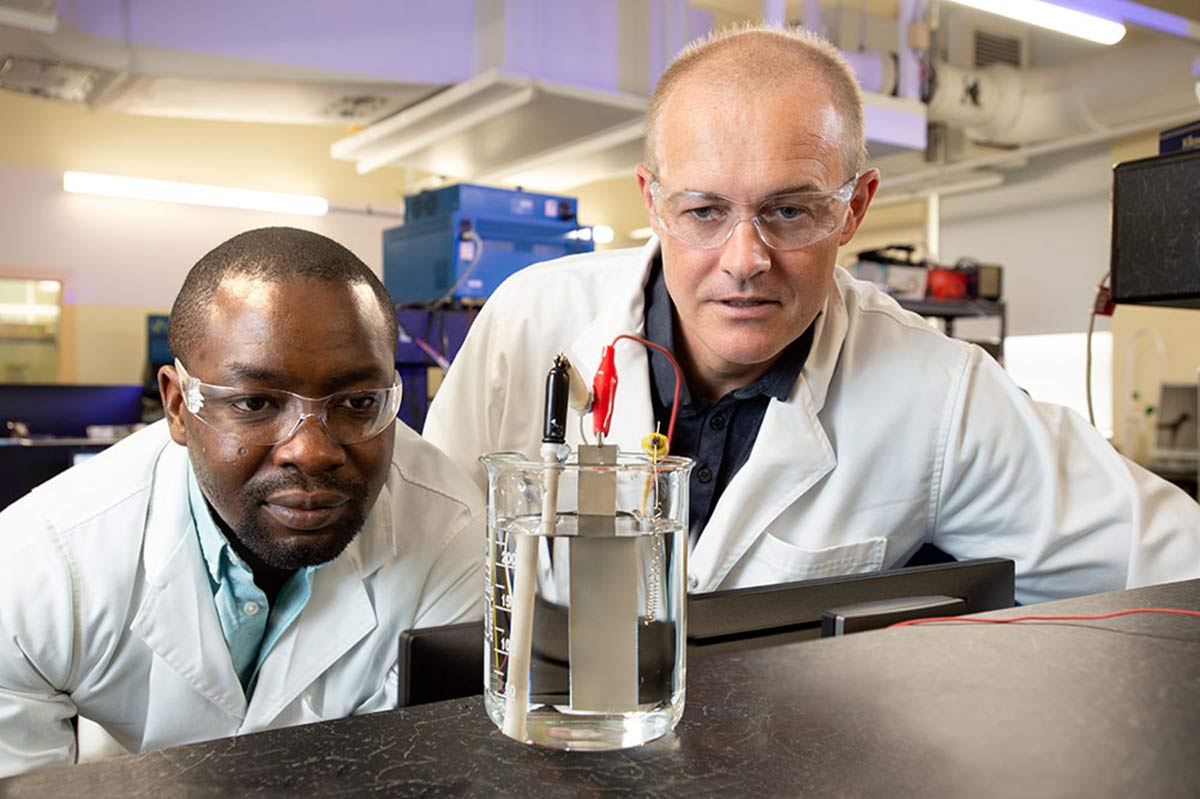

An innovative chemical process has been developed by PhD researcher Olawale Oloye and Professor Anthony O’Mullane from the QUT Centre for Clean Energy Technologies and Practices.

The complete process has the ability to absorb carbon dioxide from the atmosphere, storing it as calcium carbonate, a useful building material.

The process requires carbon dioxide and oxygen inputs, which are combined in water to produce carbonate ions (CO32-) through a process that involves the electrolysis of water. This electrolysis has the ability to be powered by renewable electricity sources like wind and solar electricity.

The CO3 is combined with calcium added to the water to produce calcium carbonate (CaCO3), storing the original carbon dioxide into a useful material, and the electrolysis process produces hydrogen as an additional by-product, providing a potential supply of the renewable fuel.

Calcium carbonate itself is an important ingredient in the production of cement, and the process could be used to produce many other materials useful for industrial processes, including strontium carbonate and manganese carbonate.

“This process involves the capture of CO2 by its reaction with an alkaline solution produced on demand, to form solid carbonate products which can be used, for example, as construction materials, thereby keeping carbon dioxide out of the atmosphere,” QUT professor Anthony O’Mullane said.

“This can be done using a simple calcium source in water. To further improve efficiency, we added a low-toxicity, biodegradable chemical called MEA [monoethanolamine] to increase the amount of CO2 drawn out of the atmosphere and into the water.”

“Given that urbanization is expected to grow over the next 50–100 years, the demand for cement and concrete will continue to increase and with it the need to significantly reduce the industry’s CO2 footprint if the world is to meet its emission reduction targets.”

The production of cement is a major source of global greenhouse gas emissions, with the production of the building material accounting for around 7 per cent of global emissions.

“We envision this technology would benefit emission-intensive industries such as the cement industry whose CO2 footprint is 7 to 10 per cent of anthropogenic CO2 emissions due to the initial clinking (heating) step that converts CaCO3 into CaO (lime) with the emission of large amounts of CO2,” O’Mullane said.

“By coupling the mineralization process to produce CaCO3 from the emitted CO2 during the clinking step we could create a closed loop system and reduce a significant percentage of the CO2 involved in cement production.”

One additional benefit of the new technique is the ability to use seawater rather than being reliant on supplies of fresh water, avoiding adding additional pressures on an otherwise scarce resource.

“We found we could use seawater once it had been treated to remove sulphates. To do this we first precipitated calcium sulphate or gypsum, another building material, and then carried out the same process to successfully turn CO2 into calcium carbonate, thus providing proof of concept of a circular carbon economy,” O’Mullane added.

The Clean Energy Finance Corporation recently tipped $95 million into the development of a ‘green’ logistics precinct in Perth, which will use a source of low-carbon cement in the construction of a major new industrial hub in an effort to reduce its embedded emissions.