Danish renewables developer Aalborg has begun construction of a custom built concentrated solar power tower system to supply, heat power and desalinated water for Adelaide-based sustainable agriculture outfit Sundrop Farms.

The first phase of the project, a 51,500m² solar field consisting of more than 23,000 heliostats will be installed at the 20 hectare multi-greenhouse facility Sundrop has been developing in the South Australian desert, 15km south-east of Port Augusta.

Aalborg’s Integrated Energy System will be the first large-scale CSP-based technology in the world to provide multiple energy streams – heating, fresh water and electricity – for horticultural activities.

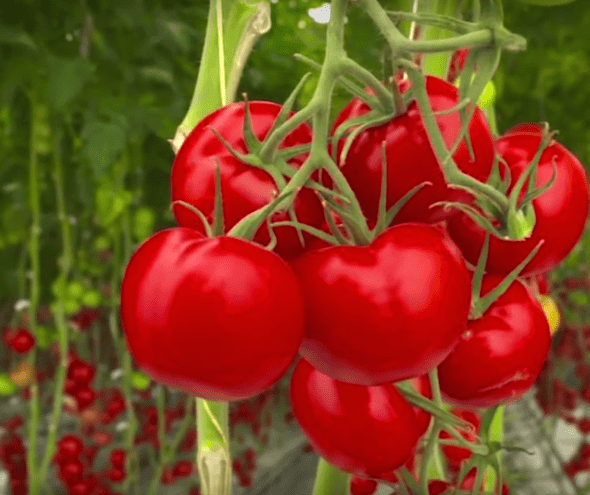

Relying, until recently, on funding from the Clean Energy Finance Corporation, Sundrop Farms successfully developed a prototype of its proprietary closed-loop farming system, growing tomatoes year-round in greenhouses using only sunlight and seawater.

Last year in December, the company secured $100 million of funding from leading global private equity investor KKR, allowing it to proceed with plans to expand the Port Augusta prototype into a 20-hectare facility, that will produce pesticide-free tomatoes annually for markets across Australia.

It has since been building four 100-metre long greenhouses at the Port Augusta site, and has secured a 10-year exclusive contract with Coles for more than 15,000 tonnes of tomatoes annually, creating jobs for up to 175 people.

The final step is the addition of Aalborg’s CSP tower technology, which will collect the sun’s rays and reflect them onto the top of a 116m high solar tower, where the collected solar energy will be converted to steam and used for multiple purposes, including seawater desalination, heating and electricity production.

According to Sundrop, truss tomatoes will be growing in the new greenhouses, using the concentrated solar technology by the first quarter of next year.

Having commenced the first phase of construction of the solar heliostat field at the site in South Australia, Aalborg aims to have the CSP tower system fully commissioned in the second half of 2016, as a working example of a new platform to address major global energy challenges.

“The Integrated Energy System is the first of its kind in the world and it changes the way we are thinking about energy today,” Aalborg CEO Svante Bundgaard.

“It is an intelligent way to supply different energy outputs at the time the industrial facility would need it while providing significant cost and CO2 savings as well.”

Sundrop CEO and founder Philipp Saumweber – a former investment banker who is based in London – says his company aims to change how agriculture is gone about, and expects the developments at Port Augusta to attract significant international interest.

“We consider ourselves a triple bottom line business: people, plant, and profit,” Saumweber told Brisbane’s Courier-Mail last week.

“We are constantly evaluating new opportunities to expand both here in Australia and in other markets.”