Solar PV is being installed faster than everything else put together (fossil, nuclear, and other renewables not counting wind) on the rooftops of homes and businesses, and in large-scale ground mounted arrays.

Since the price of PV continues to fall, and since PV is essentially unconstrained, solar PV will probably grow to dominate not just electricity production but also all forms of energy production through the electrification of transport, heating and industry.

But what happens to the solar panels at the end of life? Will solar PV waste become a major problem?

To understand the scale of the potential problem, let us assume that PV goes to the limit. Suppose that all energy is produced using solar PV and wind.

This entails complete renewable electrification of transport, heating and industry, and results in a reduction in Australian greenhouse emissions of 85%.

Complete displacement of all oil, gas and coal by PV and wind requires approximately a tripling of electricity production. So, we’re looking at a situation where 750 terawatt-hours per year of PV and wind electricity is needed.

Silicon solar cell panels comprise 95% of the world solar market and will approach 24% efficiency by 2030.

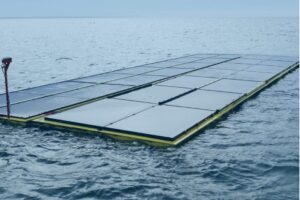

Let us assume that rooftop PV, utility PV and windfarms each provide one third of this electricity, with conservative capacity factors of 13%, 20% and 38% respectively. The required power capacities from each of rooftop PV, utility PV and wind are 230 GW, 140 GW and 75 GW respectively. (Editor’s note: Maybe not so much, those capacity factors for solar look very conservative!).

Under these assumptions, the area of required PV panel per person is 60 square metres (14 kW), producing 20 Megawatt-hours per year.

The typical panel working life is 30 years and so just 2 square metres of panel will retire each year per person, weighing 20 kg, almost all of which is suitable for recycling. This is 1% of annual solid waste generated per person and one part in a thousand of the weight of Australian annual carbon dioxide emissions per person. For comparison, a car typically weighs 1500 kg and lasts for 10 years, thus generating 150 kg of waste per year on average.

A silicon PV panel comprises mostly cover glass and aluminium frame together with small amounts of plastic, silicon and conductive metals. Excluding the frame, over 90% of the panel weight is glass. Silicon is non-toxic and is the second most abundant element in the Earth’s crust (after oxygen). The conductive metals are small amounts of copper, silver, aluminium and very small amounts of solder.

Firstly, the aluminium frame and cables are removed, and join much larger metal recycling streams. A simple method of recycling silicon PV panels is thermal decomposition.

Heat causes the thin encapsulating plastic to evaporate and the panels falls apart. The evaporated plastic is burnt to provide heat and to eliminate emissions of gases (apart from small amounts of steam and carbon dioxide). The glass adds 40% to the existing glass waste and recycling stream.

The residual silicon and conductive metals are small (one part in ten thousand) additions to much larger existing ceramic and metal waste streams.

During the early growth of an industry the logistics to deal with a new product at end of life might not initially keep up.

This currently applies to some extent to both lithium batteries and PV panels, but the mature lead-acid battery industry provides a good example of high collection rates.

As the PV industry grows and matures, businesses will develop for sustainably managing the PV panels at end of life.

Managing PV modules at end of life will not be a limitation on complete replacement of fossil fuels for our energy needs by solar PV and wind.

The amount of PV materials to be recycled will remain comfortably below existing waste and recycling streams and hence no special disposal and recycling technology or logistics is required.