Norwegian companies Norsk Hydro and World Wide Wind announced this week plans to use sustainable and recyclable materials such as aluminium in the construction of floating offshore wind turbines.

Norsk Hydro, a Norwegian aluminium and renewable energy company, signed a Letter of Intent this week with compatriots World Wide Wind AS (WWW), a relative newcomer to the scene which has designed a novel offshore wind turbine design which uses a counter-rotating vertical axis turbine.

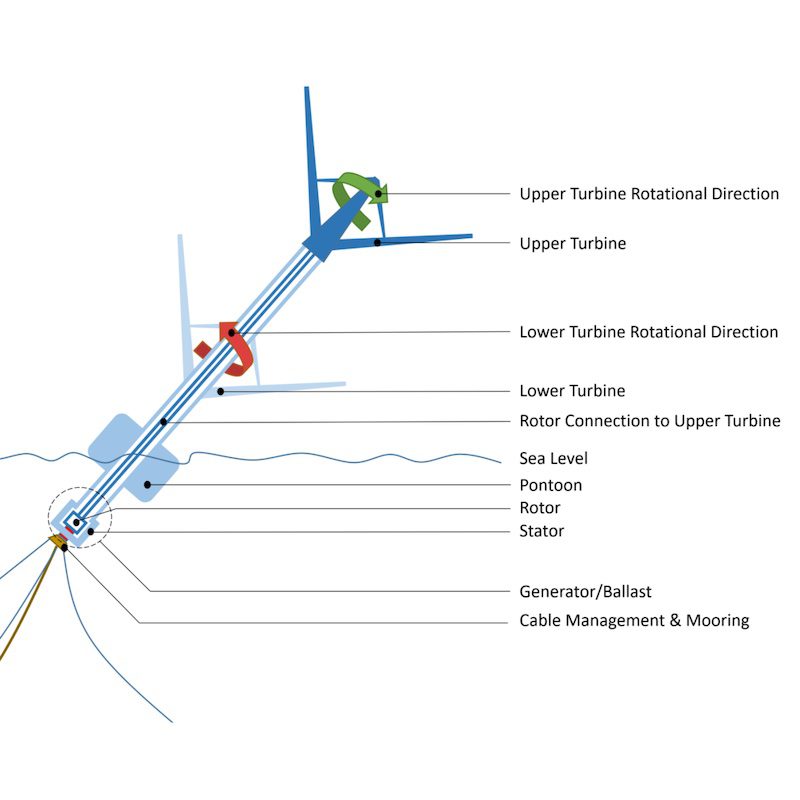

Founded in 2021, WWW’s floating offshore wind turbine uses two counter-rotating turbines which are tilted with the wind, similar to how a sail boat works. Requiring no nacelle, gears, cooling, or yaw, the company claims their turbine is scalable up to 40MW and up to 400-metres in height.

In addition to requiring fewer components, the counter-rotating turbine also reduces the wake effect of large-scale wind farms and allows for greater turbine density – which means wind farm zones could pack more larger turbines into their leased areas.

The new agreement with Norsk Hydro will see the two companies explore the use of aluminium in the design of its floating wind turbines. The goal of the two companies is to use sustainable and recyclable materials such as aluminium in the construction.

“Today, wind turbines used for offshore floating wind have more or less the same design as turbines meant for land-based wind,” said Trond Lutdal, CEO of World Wide Wind. “In effect we are moving a land-based technology offshore.

“In World Wide Wind we are developing a new type of floating wind turbine for deep waters, with significant benefits relative to current technology in terms of energy production, cost, scalability, and environmental footprint. The new design gives us an opportunity to use aluminium components in parts of the wind turbine structure.”

“Having Hydro as a partner in developing our turbine using sustainable materials as aluminium, is a big step forward for us. Use of local content will be part of our common strategy going forward, he continues.

Collaboration will focus on the detailing of a turbine design including the use of aluminium, followed by production of prototypes and the building of a consortium of industrial partners.

“[Norsk] Hydro sees the potential for increased aluminium in many industries, incl. wind power,” added Trond Furu, research manager at Norsk Hydro Corporate Technology.

“For Hydro this is an entry into the wind turbine production chain and at the same time we are strengthening our position within renewable energy.”