Australian battery materials start-up Next-Gen Energy Technology has signed a partnership with German technology giant Siemens to accelerate the local development of battery materials, with a goal to building the first materials manufacturing plant outside of China.

Next-Gen Energy Technology (Next-Gen) and Siemens announced on Wednesday that they had signed a memorandum of understanding (MoU) to accelerate the development and manufacture of innovative materials for battery firming technology.

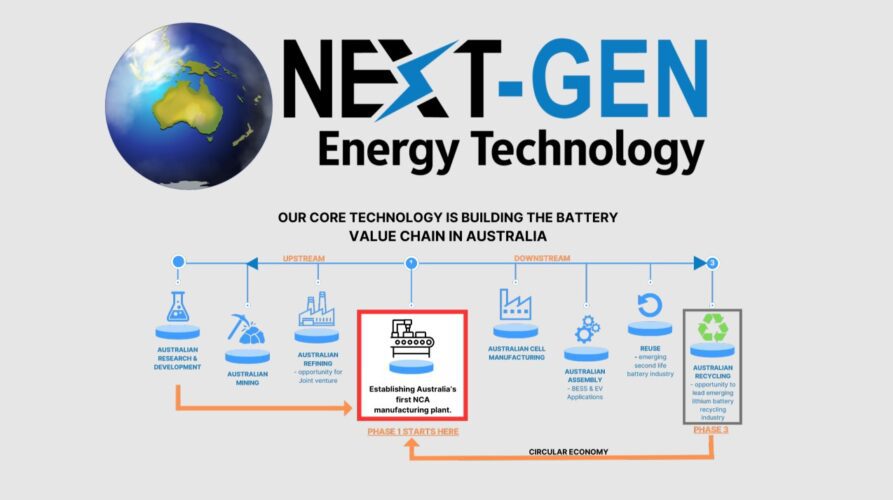

Founded in 2020, Next-Gen is headquartered in the Melbourne suburb of Box Hill and specialises in advanced ternary cathode materials for lithium-ion batteries, primarily used in electric vehicles and battery energy storage systems. The company’s lithium nickel cobalt aluminium (Li NCA) battery cells offer superior safety performance and are also more sustainable and cost-effective due to the reduced need for cobalt.

The MoU signed between the two companies is designed to support Next-Gen’s efforts to build a materials manufacturing plant in Australia which would produce its Li NCA cathode materials.

If successful, this would be the first battery materials manufacturing plant to exist outside of China.

Despite mining being done across multiple states in Australia, these critical minerals are nevertheless shipped to China for refining and processing. Creating a local battery materials manufacturing plant would act as a huge first step to wresting away China’s control of battery manufacturing.

“Our Lithium NCA solution is world first, transformative and nation building,” said Andrew Cooper, CEO of Next-Gen.

“We are 100% Australian owned and operated but with a depth of knowledge in energy storage materials development. We have some of the world’s leading experts in lithium technology who have worked with us to develop our patented technology.”

“Our process will dramatically reduce the carbon footprint current value chain practices employ,” said Cooper, who added that “by onshoring manufacturing for the battery chain here in Australia, we can reduce the industry’s carbon footprint dramatically – particularly reducing scope three emissions which are part of Net Zero commitments.”

Cooper hopes that the new partnership with Siemens will help to create employment and export opportunities for Australia, suggesting that the planned materials manufacturing facility “will be the centrepiece for the battery value chain and has already attracted both upstream and downstream global investment and will help strengthen Australia’s sovereign manufacturing capabilities.”

Specifically, Next-Gen will draw on Siemens’ core expertise in digitalisation, automation, and electrification, in order to scale up onshore production of its battery manufacturing technology.

“Technology and digitalization are the key to increasing manufacturing complexity and sovereign capability whilst accelerating sustainability in Australia,” said Darryl Kaufmann, head of digital industries for Siemens in Australia and New Zealand.

“Being the largest automation and industrial software company in the world, we’re making our technology more accessible than ever so that companies like Next-Gen can bring their innovations to life through powerful tools such as digital twin.

“We’re proud to extend our support to organisations such as Next-Gen who are pushing the boundaries of local innovation, manufacturing and supply chain.”