It’s not easy finding a hotel room in Port Augusta these days, and it’s not because of tourists or grey nomads. After striking out with a number of motels I finally found one with a mobile number on a post-it note stuck to the dusty front-door. Frank, the proprietor, tells me he’s got one room left that he saves for regulars, but to do that he had to unblock it from the booking system. “You probably thought you were just gonna waltz in here and get a room, no sweat,” he suggests. “But you’d be struggling. Port Augusta is packed.” When I ask why, he replies: “Oh, the boys working on that wind farm, of course.”

The next day I find myself stuck in a traffic jam of white Hilux utes and discover there is not just one big wind project around here, there are two. East of town, on the road to Adelaide, is the Port Augusta Renewable Energy Park, the country’s biggest hybrid wind and solar project which, when finished, will feature 210MW of wind energy capacity and 107MW of solar. And then on the other side of town there is phase 2 of the Lincoln Gap wind farm, that will boast a total of 464MW when finished. No wonder there’s barely any rooms available to sleep in, or even much room to move on the roads.

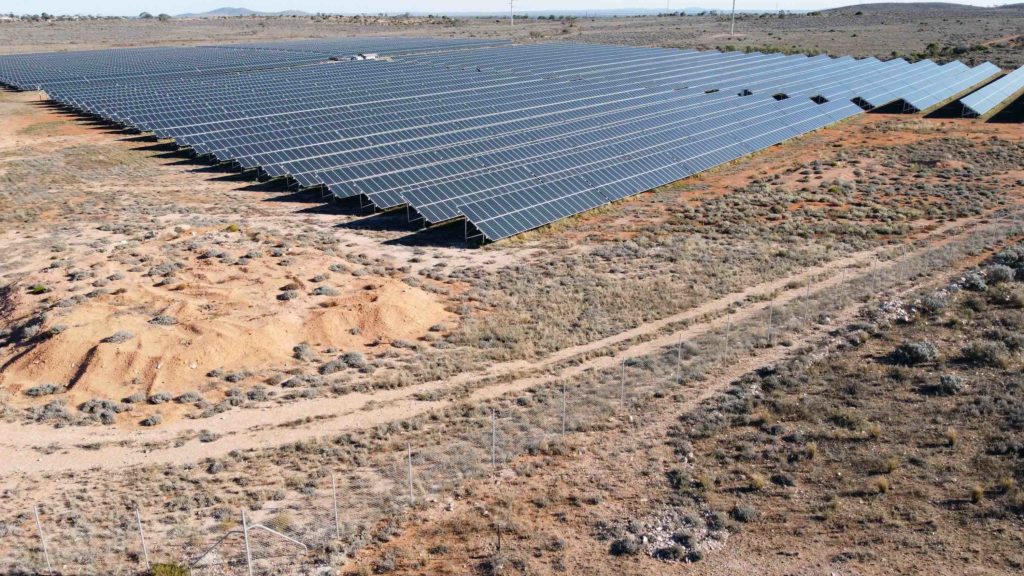

Five years after the closure of South Australia’s last coal-fired generators, the Port Augusta region – which includes the neighbouring cities of Whyalla and Port Pirie, finds itself in the middle of a renewable energy boom. Already complete is the Bungala solar farm, which at 220MW ranks among the biggest in the country, and there is a host of different pumped hydro projects vying for funds and contracts, including those at Goat Hill just behind Lincoln Gap. And there is also the 280MW Cultana solar farm near Whyalla and the 100MW/200MWh Playford Big Battery that have approvals and contracts, even if their development has been held up by the financing issues for Whyalla steel owner GPG Alliance.

Playford will be built right next to the Davenport sub-station that once served both the Playford and Northern coal generators. Also being built nearby are the first of several synchronous condensers that will mean much less gas generation is needed to support the grid. These will help unlock the artificial restrictions on wind and solar output in the state and mean that the pattern of repeated interventions by the market operator will be dramatically reduced, paving the way for South Australia’s world-leading share of wind and solar to jump even higher.

The replacement of decaying fossil fuel assets for renewable energy projects is an arresting symbol, especially to a community that has had to co-exist, for generations, with the pollution of coal fired power. Once infamous for being blanketed by fly ash, lung cancer in Port Augusta was determined in one study to be double the national average. The promise of renewable energy as a way of improving local health was instrumental in generating community support for the new projects.

In 2017, a $650 million solar thermal power plant with storage using molten salt technology was announced for a site 30km north of the city. A year later these plans were scrapped when the owners, the now disbanded US firm SolarReserve, failed to get funding. For a community that had campaigned hard and engaged many national partners to ensure success, this defeat was a blow. Yet the appetite for renewables had been established.

Soon after, UK billionaire and green steel advocate Sanjeev Gupta stepped into the breach, with an announcement to build the Playford Uility Battery (or PUB for short), and the Cultana solar farm. For all the promise and the booked hotel rooms and the bumper-to-bumper utes along the highways, some locals are starting to wonder what’s in it for them, at least in terms of jobs.

Garry Bridgman has been working at the steelworks’ pellet plant for six years and had worked at Brambles for 18 years before that. He can remember when Gupta came to town for what is now referred to today, with growing irony, as ‘the big reveal’. “It was the first time I’ve ever seen the Prime Minister, the Leader of the Opposition, the Premier, the leader of the opposition of the state and the mayor,” says Garry, “telling us it’s going to be 70,000 or 80,000 people and there’s going to be a big 10 level resort by the beach.” Back then Whyalla had around 21,000 people, as it still does today.

“We’ve gone from (promises of) an expansion into a big city to being told we might virtually be a ghost town – it’s all feast and famine, feast and famine.” Garry has two daughters, one is in university while the other is working. That they are out of school makes things easier. Garry has something I saw throughout Whyalla – a steely resilience gained from a living shackled to a commodity price.

When the price of steel or iron ore is up, then the town’s prospects are good, house prices go up and everyone gets a little richer. The opposite happens when prices go down. Right now the price of iron ore is at a 10-year high and is helping to bolster the entire Australian economy. This does a lot to allay anxieties throughout town. “We’re a good business making money – worst thing that could probably happen is that we’d have another name on our shirt.”

Driving south along the Lincoln Highway from Port Augusta the region’s renewable assets are as plain as day. The road passes the sweeping turbines built on the jutting ridge at Lincoln Gap. The sky is blue as it is 300 days a year, and it sits low above the wide red earth dotted with saltbush. In the distance is the gulf where the desert suddenly meets the sea with little in between.

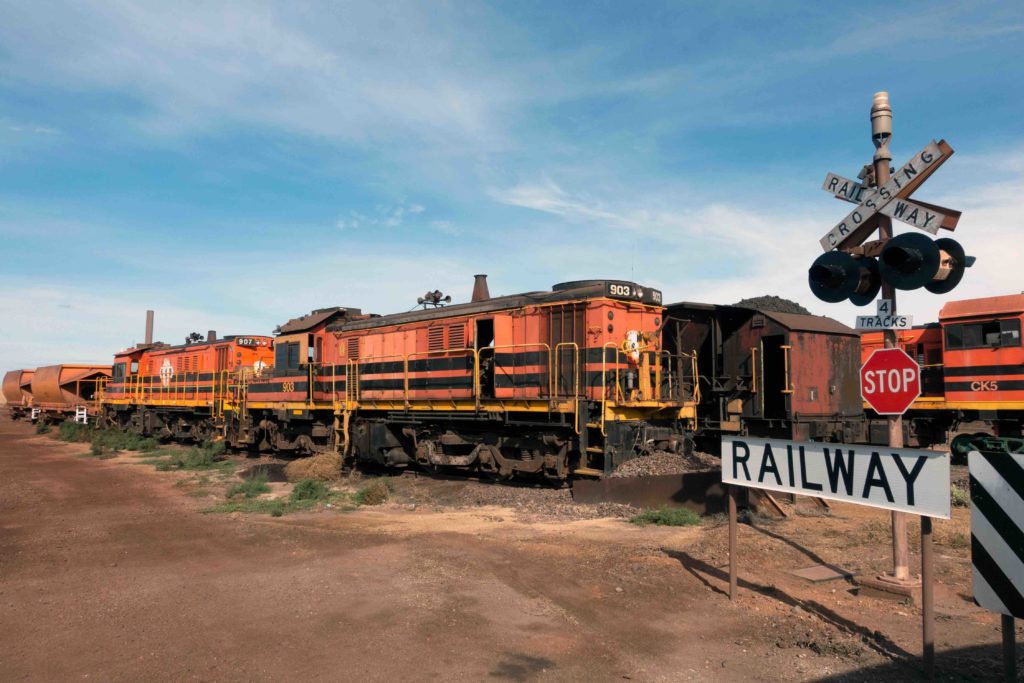

On the outskirts of Whyalla though, you enter another world. The first thing you see of Liberty Steelworks are the billowing clouds of steam and a sprawling complex of sheds and factories each a different shade of rust encrusted with soot. Then you see a network of elevated pipes that thread through ever-growing hills of grey slag, black coking coal and yellow sulfur.

Far more than a town with a steelworks, Whyalla is a steelworks with a town. This is why when Gupta announced the Liberty Steel takeover in 2017, he became known as the ‘saviour of Whyalla’. His plans were indeed ambitious: together with the PUB and Cultana solar farm, was a $1 billion overhaul of the steelworks to make it the first producer of green steel in the country. Green steel is steelmaking without the carbon emissions. This is presumed to be done both with green hydrogen in the place of coking coal or with an electric arc furnace. Both require expensive modifications to existing facilities and huge amounts of renewable power.

The Greensill collapse in March began a desperate battle to keep GFG Alliance’s empire afloat. It includes other ageing assets like power stations and smelters in Romania, Czechia and the UK, all of which were bought with similar promises for significant upgrades from their new owner. A US financier, White Oak, may come to the rescue, but until investigations by the Serious Fraud Office in the UK are resolved, the plans for Whyalla steelworks remain beneath a pall of uncertainty.

There is still significant loyalty to Gupta in Whyalla, and for good reason. When purchased from Arrium in 2017 by Gupta Family Group’s Alliance (GFG) the steelworks was in dire straits. A year before the sale it was running at a $60 million loss and there was talk of mothballing the whole operation which employed 1100 workers and 450 contractors. This would have been devastating to Whyalla and would have reverberated throughout the entire region. As Garry suggested “if this place goes under then it’s virtually a fishing, retirement town.”

Gupta’s investment in the Upper Spencer Gulf was sold as more than just an opportunistic buyout of an ageing asset on the brink of insolvency. Instead, there was a holistic vision to make the steelworks part of the “green steel” revolution and in doing so make the old and rusting new and shiny again. This was seductive along the breadth of the political spectrum. Jobs and industry for the free-marketeers and, for the greenies, an economic plan that works with renewables rather than against them.

Gupta’s plans also played to a yearning for sovereignty. “We as a country can’t be in a position where we can’t make steel,” says fiery independent Senator Rex Patrick. The alternative for Australia is to be little more than a quarry for the world. Garry agrees: “Australia needs its steel, steelmaking is part of what we do. What would be left in Australia? We lost Holden, we lost Mitsubishi, we lost Ford.” Australia, the reasoning goes, must use its mineral wealth for something greater and more imaginative than the exporting of raw ore.

Professor Ross Garnaut has written extensively about Australia’s potential to become a renewable energy superpower and says the Upper Spencer Gulf has great potential as a zero emissions industrial area, thanks to its renewable energy resources, industrial history and the rich minerals deposits. Industrial history provides the “skills and industrial traditions and the services infrastructure…,” Garnaut explains, adding that these are “major assets and it would be hard work and take a long time and cost a lot to start that from scratch.”

And it’s not just the hematite and magnetite iron ore mined from the Middleback ranges and fed into the steelworks. The broader region is home to deposits of copper, uranium oxide, graphite, quartz and sand, and the latter two can make green and pure silicon for microchips and solar cells. Included in the Upper Spencer Gulf’s industrial capacity too is Port Pirie which has the world’s largest lead smelter and can process silver ore.

The market for green metals is expected to surge in the near future to support the worldwide renewable boom and the transition to electric vehicles. Australia’s main export partners Japan, China and South Korea, have signed onto net zero emissions targets, to be achieved by the middle of the century, or 2060 in the case of China, but they lack the renewable resources for green metal making. This presents a unique opportunity for Australia to reposition itself higher along the supply chain, delivering bigger profits and a more sophisticated industrial base.

This is why Gupta’s promise was so attractive. He had integrated each moving part of this vision into a single cohesive machine. He would build the renewables, own the mines as part of the steelworks purchase, then use the profits to upgrade the mill to process it all. What’s more, there was also access to the Gulf and the deepwater port at Bonython from where it all could be shipped around the world.

“GFG’s vision for Whyalla has not changed,” promises a GFG spokesperson via email, “the transformation program, which will ultimately see renewable energy power the steelmaking process and hydrogen replacing coking coal, continues to progress with the projects in advanced development stages.” They have also not changed their pledge to become carbon neutral by 2030.

Andrew Mayne is not so sure. “I’m over the talk,” he says bluntly, “I’ve got a mum who’s 72, she’ll watch the tele and say ‘oh that’s brilliant what’s gonna happen.’ [I say] Mum don’t believe everything that’s going on.” Andrew was born in Whyalla and joined the Steelworks as an apprentice in 1991. Today he works at the Iron Duke Mine for Simec, a GFG subsidiary.

“People are buying houses at a price that they’re never going to recoup. People are on a bit of a rollercoaster.” The Australian Manufacturing Workers’ Union, of which Andrew is a delegate, is currently in negotiations for an enterprise bargaining agreement with GFG. They are being told they will not receive a pay rise despite the once in a decade ore prices. “You gotta keep giving giving giving for potentially a pipe dream to happen,” Mayne says.

While Mayne is sceptical, Garnaut is more optimistic: “Unless Australia were to muck it up with incoherent policy, and it would be hard to muck up that much, but we’re trying, the world is looking for this, and this region is ready to go.” And Zen Energy, of which Garnaut is chair and biggest shareholder, is still independently pursuing renewable projects in the region.

More optimistic still is South Australia’s minister for energy and mining, and local MP, Dan van Holst Pellekaan, who continues to regard the Upper Spencer Gulf as “epicentre of renewable energy generation in South Australia and Australia and some people even say the world.”

Van Holst Pellekaan, a Liberal, lives in the area and is clearly excited by the transformation happening within his portfolio and under his watch. Close to hand are the present renewable stats that sound like other states’ future targets. “This calendar year we are operating on 60% renewable energy and 40% gas generation – AEMO has predicted by 2025 this will be up to 78% renewable energy and 22% gas.”

Indeed, van Holst Pellekaan is adept at sidestepping the traps placed there by the conservative Coalition between Liberals and the National Partyt at a federal level: “Instead of making energy disruptive… we’re making it useful,” he says. And, “as well as it being clean…, it will be cheap.” And when natural gas is inevitably raised, its tenuous truce with renewables is lauded with the skill of a seasoned diplomat … “in a slightly ironic way – they [gas generators] will allow us to have even more renewables … because we can rely on it to fill the gaps quickly.”

Often though, a boom is accompanied by a bust. As van Holst Pellekaan concedes, renewables require hotels full of workers during construction but comparatively modest numbers of jobs once up and running. Yet he has his own vision “it’s not just about the building of projects for the next 10, 20, 30 years…we have the opportunity to make the Spencer Gulf a Silicon Valley type location.”

This is more than just a neat sound byte. The Upper Spencer Gulf is attracting emerging technologies. Sundrop Farm’s towering heliostat is the shining beacon of reflected solar that glows white with 39MW of thermal power and greets the traveller arriving from Adelaide. This technology is a world first and grows 13,500 tonnes of truss tomatoes yearly with “sunlight and seawater”.

Also slated to begin around 2025 is a demonstration unit 30 kilometres north of Port Augusta that uses technology developed by the CSIRO to store heat using liquified silicon. It is named 1414 Degrees after the temperature that silicon melts. To achieve this, 1414 Degrees has taken over the site of the Aurora project from SolarReserve. It is ambitious not just because it is the only operation at commercial scale using liquid silicon, but it is positioned to supply high-grade heat for an industrial base that has not even been built yet.

“By having a heat source there we may be able to attract other industry and other opportunities to that science as well,” explains the chief operating officer Jordan Parham, but he concedes that right now “the only customer is a bunch of saltbush”.

Whyalla Mayor Clare McLaughlin is also lobbying hard for her city to become one of Australia’s key green hydrogen hubs. “We need to diversify our economy,” she says. Whyalla is a strong contender because of the renewable resources available, Port Bonython as a convenient point of export together with the prospect of using hydrogen in the steelworks.

Of course, all these visions are predicated on the availability of vast amounts of renewable electricity that even current plans would struggle to meet. But on the ground, those renewable projects trying to join the grid are having their own problems. The Lincoln Gap Wind Farm is wrestling with compliance, having to rebuild their profile of electricity generation each time another supplier joins the grid.

“The problem is you’re trying to hit a moving target – the amount of money we’ve spent resubmitting, resubmitting, resubmitting on different packages – it’s cost us a fortune in consultation fees. All that cost ends up in the system and needs to be recovered,” says Charles Rattray, managing director of Nexif, the owner of Lincoln Gap.

Rattray acknowledges the efforts by the state’s transmission compnay ElectraNet to try and solve problems whenever possible. But Lincoln Gap is not the only project facing problems. The second stage of Bungala solar farm also experienced severe delays before commencing operation, while 1414 Degree’s share price dropped by 40% last year when its technology failed to meet key efficiency metrics.

The community, meanwhile, is getting used to having its fortunes constantly in a state of flux. In my discussions in Port Augusta and Whyalla, the constant refrain was to the the “‘rollercoaster”, or “yoyo,” a never-ending cycle of fluctuating commodity prices, the GFC and the availability of foreign investment and demand. Here the renewable boom is simply the latest trend. All factors of their future remain largely outside the control of the residents here.

“The ladies and the guys that keep this company going will turn up every day and keep doing what they’re doing. Everyday they learn a little bit more regardless of who owns it, regardless of what’s in the media, regardless of how bad it looks,” says Steve McMillan, who started as an apprentice at the steel mill in 1988 when it was owned by BHP. After working in the steelworks for 21 years, today Steve is a Regional Organiser for the union.

“When they’re saying ‘it’s gonna be closed and nobody wants to buy it and it’s a piece of junk,’ they keep turning up. They keep running the place.” It’s a comment that struck me when loading my luggage into the rental car for the last time and airing some anxieties about a diary full of political interviews. “Don’t worry about ‘em mate,” Frank suggested. “They’re full of shit anyway!”