Iron ore mining giant and now green energy investor Fortescue Metals has provided some meat to the bone of its decarbonisation targets, outlining plans to build multiple gigawatts of wind, solar and battery storage for its Pilbara operations.

Fortescue has hugely ambitious green hydrogen plans and is currently canvassing at least five large scale projects in Australia, the US, and elsewhere in the world, but it has also vowed to reach “real” zero emissions, rather than “net zero” on its domestic emissions, including its massive iron ore mines.

In a presentation to visiting analysts and investors last week, Fortescue described how it intended to build more than one gigawatt of solar, around one gigawatt of wind energy, and around four gigawatt hours of battery storage to cut its reliance on expensive, and polluting gas generation and diesel.

One 60MW solar farm has already been built at Chichester by Alinta, and plans for another 150MW of solar and two small battery projects are well advanced. The plans also include 750kms of transmission lines.

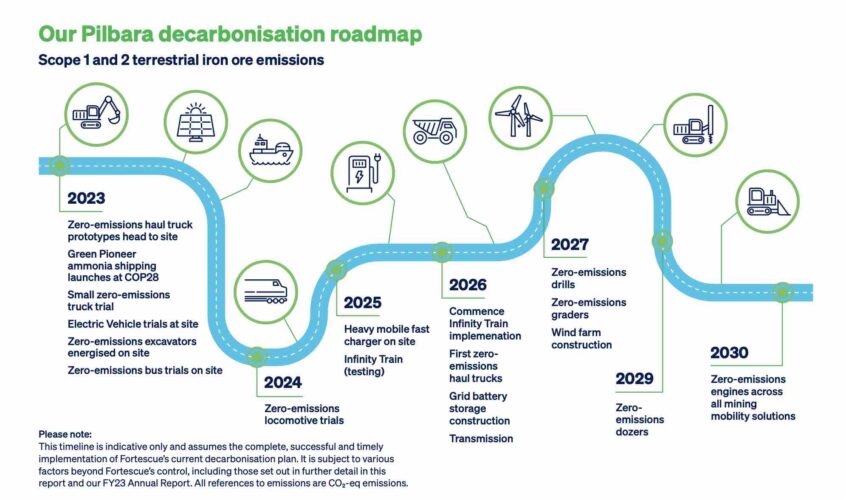

An indicative timeline published by Fortescue suggests most of the battery storage will start construction around 2026, with the wind projects to start construction in 2027. The locations of these projects are not yet finalised.

Fortescue is not alone in seeking a transition to renewables in the Pilbara, with Rio Tinto and BHP also laying out major investment programs in wind, solar and storage, although they are opting to use offsets. Gina Rinehart’s is less forthcoming on the transition to the green energy she repeatedly criticises.

The big iron ore miners have agreed with local network companies, generators, and the state government to bring an end to their quasi feudal system of poorly linked, private electricity networks, and create a renewable dominated grid for all to share in the Pilbara.

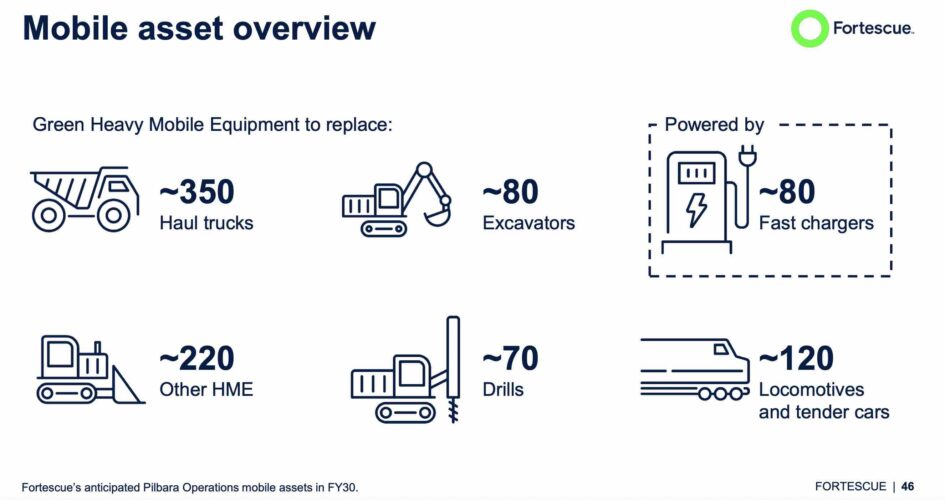

Zero emissions mobility is also high on the agenda. Fortescue’s presentation discussed plans to switch its fleet of heavy haul trucks, excavators, cars, utes, drills and locomotives to a mixture of fully electric of hydrogen fuel cell vehicles.

The first trials of electric 260 tonnes haul trucks has already commenced in the Pilbara, along with a trial of a 3MW charging station being built and refined by the WEA (Williams Engineering) company that Fortescue bought last year.

A hydrogen fuel cell haul truck is also being trialled at one of its mine sites, and this month it took deliver of an electric excavator, made by Liebherr, which it says is its first piece of “cabled” equipment. It will be powered by its existing electric supply under the renewable energy network is established.

The company says it has also successfully modified a diesel ship engine to run on green ammonia, and it plans to carry out the first sea trials on board the Green Pioneer later this year.

Two electric locomotives are also due to arrive in 2024, and Fortescue is still working on its so-called “Infinity train” which is designed to recharge huge batteries on the downhill, full laden run from the mines to the port, leaving it with sufficient charge to make the return mineral free journey back to the mine.

The Fortescue presentation also discussed prototype exchangeable batteries, with eight sub-packs per heavy haul vehicle, also being designed by WAE. It says the modular battery system will have “flexible” chemistry and will be scaleable and upgradable. It is also trialling off-grid hydrogen fuel cell systems.

Fortescue estimates it emits more than 2.5 million tonnes of CO2 equivalent each year from its mining operations, including shipping and tug boat operations.