Solar power is now cheaper than ever, and battery prices are falling fast.

That’s great news for homes and businesses, which are cutting bills and emissions with clean energy.

But for Australia’s most energy-hungry industries, such as steel, aluminium and cement, cheaper equipment isn’t enough.

Our recent research shows that even as solar and batteries keep getting cheaper, the drop in industrial electricity costs soon hits a bottleneck.

The real breakthrough won’t come from cheaper technologies alone, but from using them more smartly.

Why is industry difficult to decarbonise?

Many industrial operations can’t simply switch off when the sun sets. Steel furnaces, aluminium smelters, and cement kilns must run continuously, consuming hundreds of megawatts of power as much as a medium-sized city.

They are highly sensitive to interruption. Even a few minutes interruption can cause costly, sometimes irreversible, damage.

Today, most of this energy comes from coal or natural gas, emitting large amounts of carbon dioxide to the atmosphere. As fuel prices fluctuate and carbon regulations tighten, industries are facing challenges to stay market competitive while cutting emissions.

According to the Australian Energy Market Operator (AEMO), national electricity demand could double by 2050 as industries electrify. This means the future of Australia’s clean energy transition depends on how quickly industry can change their energy source.

Cheaper solar and batteries are important, but not a silver bullet

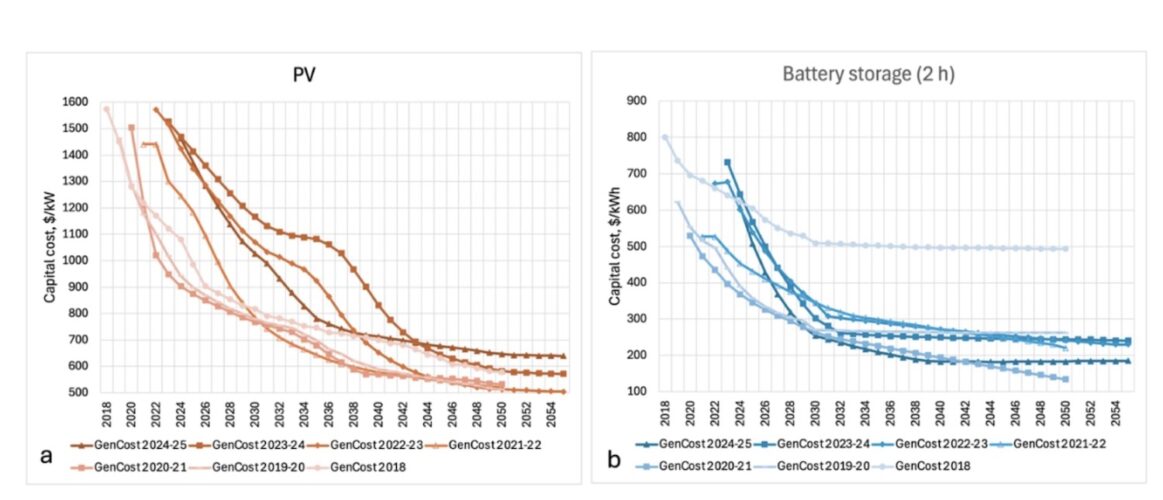

Over the past 15 years, the costs of solar and batteries have fallen by about 90%, driven by technology advances and economies of scale. According to the latest GenCost report, renewable technology costs are expected to keep falling over the next decade.

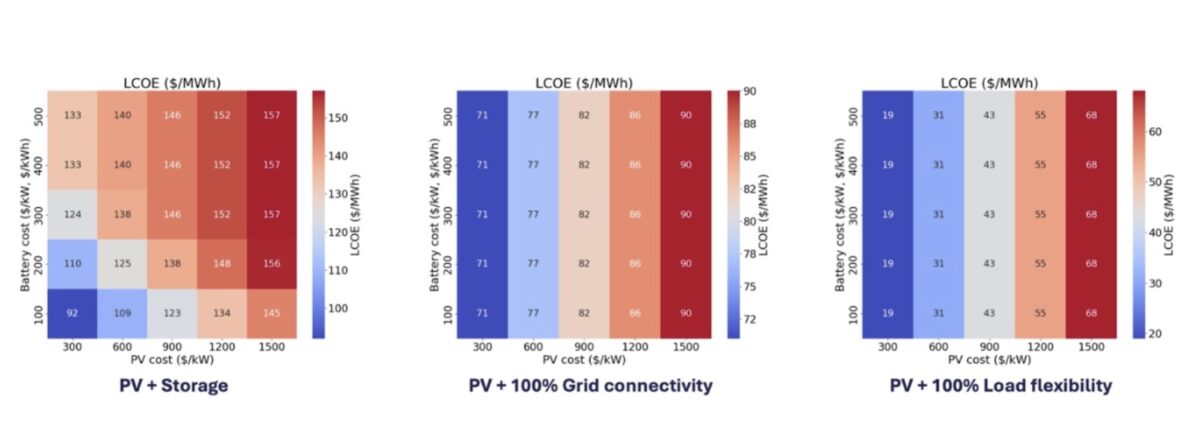

In our research, we tested future scenarios where solar and battery costs fall from the current levels by 20%, 40%, 60%, and up to 80%.

The results show that industrial electricity costs decline more slowly than the technology costs themselves. Even in a case where both solar and battery costs fall by 80%, the cost of industrial electricity falls by only 41%.

Why does the drop level off? The key issue is energy spillage. When solar generation exceeds industrial demand and storage capacity, the surplus energy is curtailed.

This means the effective cost of the electricity delivered to the factory doesn’t fall as fast as the technology cost. During long cloudy days, the need for storage and backup grows even further.

So, no matter how cheap solar panels become, if that energy can’t be efficiently used, the electricity cost can’t keep falling.

A smarter way: Grid interaction and load flexibility

Our research shows two strategies can make renewables really work for industry: connecting smartly with the grid, and changing how factories manage their energy use.

First, better grid interaction. Instead of running in isolation, factories can interact with the grid during shortfalls or when solar generation is high. The smarter coordination can cut electricity costs by up to 42% and make renewable integration much easier.

However, the benefits depend on grid access and electricity pricing. In the long term, industrial hubs could be linked by regional transmission networks designed for renewable energy sharing.

Second, more flexible demand. Flexibility doesn’t mean interrupting operations. With onsite heat and hydrogen storage, industries can keep running continuously while making the most efficient use of solar electricity. This can lower electricity costs to less than one-third of natural gas power.

To make this happen, governments and energy markets will need to provide the right support, for example, dynamic electricity pricing or demand response incentives that reward flexibility.

Rethinking industry for a renewable future

The future of clean industries will not only depend on cheap solar panels and batteries. It will also rely on how smartly we use them. Integrating flexible industrial processes and smart grids can deliver lower electricity costs and more reliable supply.

Governments can play a key role in turning falling technology costs into lower electricity prices:

- Encourage network development in industrial hubs and align them with AEMO’s long-term grid planning.

- Use policy incentives and market signals to support investments in flexible demand and onsite energy storage.

- Support project demonstrations through research-industry collaborations, helping translate research into real-world applications.

Australia has abundant solar resources, and some of the world’s richest mineral reserves, such as iron ore, bauxite, and rare earths. Used smartly, cheaper renewable technologies could power Australia’s transition to a global supplier of green products.

Projections for future PV and battery costs before and after COVID-19. Data source: GenCost reports 2018 to 2024-25

Sensitivity of industrial electricity costs to PV and battery cost reductions under three system designs. Grid interaction and load flexibility strategies can lower electricity costs by up to 42% and 80%, respectively. Source: Lu et al., 2025

Dr Bin Lu is a Research Fellow at the Australian National University School of Engineering