Electric cars are quickly overcoming the hurdles of cost and range anxiety, but one area that still needs improvement is the added weight of big battery packs. UK-based Cenex has just completed a two-year project to reduce both the weight and cost of EV batteries, succeeding by shaving 99 pounds, or about 41% of the weight off a standard EV battery, reports Green Car Congress.

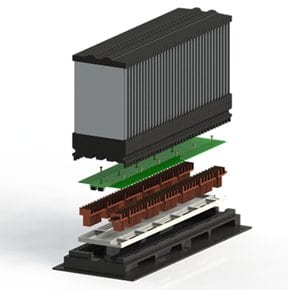

Cenex also achieved a 63% reduction in the cost of non-cell battery components, and ultimately the company hopes to enable mass production of lower weight and cost battery packs. Cenex made these weight and cost savings by eliminating the need for wires and screws in the battery pack, massively reducing the number of battery components; in two similarly-sized 4 kWh battery modules, the EV-Lite project used just 196 separate components, compared to over 800 in a conventional battery pack.

Cenex also developed an innovative safety feature which isolates individual cells in case of a fire, and the team derived five different patents for their efforts. Considering that the average EV battery is complicated, costly, and in the case of the Tesla Model S, can weigh upwards of 1,300 pounds. Reduce that by 40%, and you just shaved over 500 pounds from the curb weight of the Model S, which would mean more range and better driving characteristics.

Lighter batteries have a lot of benefits, and once automakers overcome the bugaboo of weight, we should start seeing some really long range EVs.

Source: CleanTechnica. Reproduced with permission.