Monash University researchers have made a breakthrough in the development of lithium-sulfur batteries that they believe could yield a cheaper, greener and more efficient energy storage solution – that could be made in Australia.

In a study published by the Royal Society of Chemistry, the team from the University’s Faculty of Engineering have created a new lithium-sulfur battery interlayer that promotes “exceptionally fast” lithium transfer, while also improving the performance and lifetime of the batteries.

Already, lithium-sulfur (Li-S) batteries have the potential to store two-to-five times as much energy by weight than the current generation of lithium-ion batteries, which has offered great promise for the storage of renewable energy and for longer-range electric vehicles, in particular.

What has been standing in the way of their adoption, however, has been the fact that the electrodes in lithium-sulfur batteries tended to deteriorate rapidly, causing the batteries to break down.

According to the study by the Monash research team, led by Professor Matthew Hill, Dr Mahdokht Shaibani and Professor Mainak Majumber, the new interlayer delivers high capacity and long-life.

Essentially, the discovery enables the charge and discharge of batteries and discharge of energy at a much faster rate than previously offered. For an EV, the team says this breakthrough could mean only needing to re-charge once a week.

“A lithium battery interlayer sits in the middle of the battery and keeps the electrodes apart, it helps lithium get from one side of the battery to the other faster,” said Professor Hill.

“The new interlayer overcomes the slower charge and discharge rates of previous generation lithium-sulfur batteries.”

“The interlayer stops polysulfides, a chemical that forms inside this type of battery, from moving across the battery; polysulfides interfere with the anode and shorten the battery life,” said lead author and PhD candidate Ehsan Ghasemiestabanati. “It means the battery can be charged and discharged as many as 2000 times without failing.”

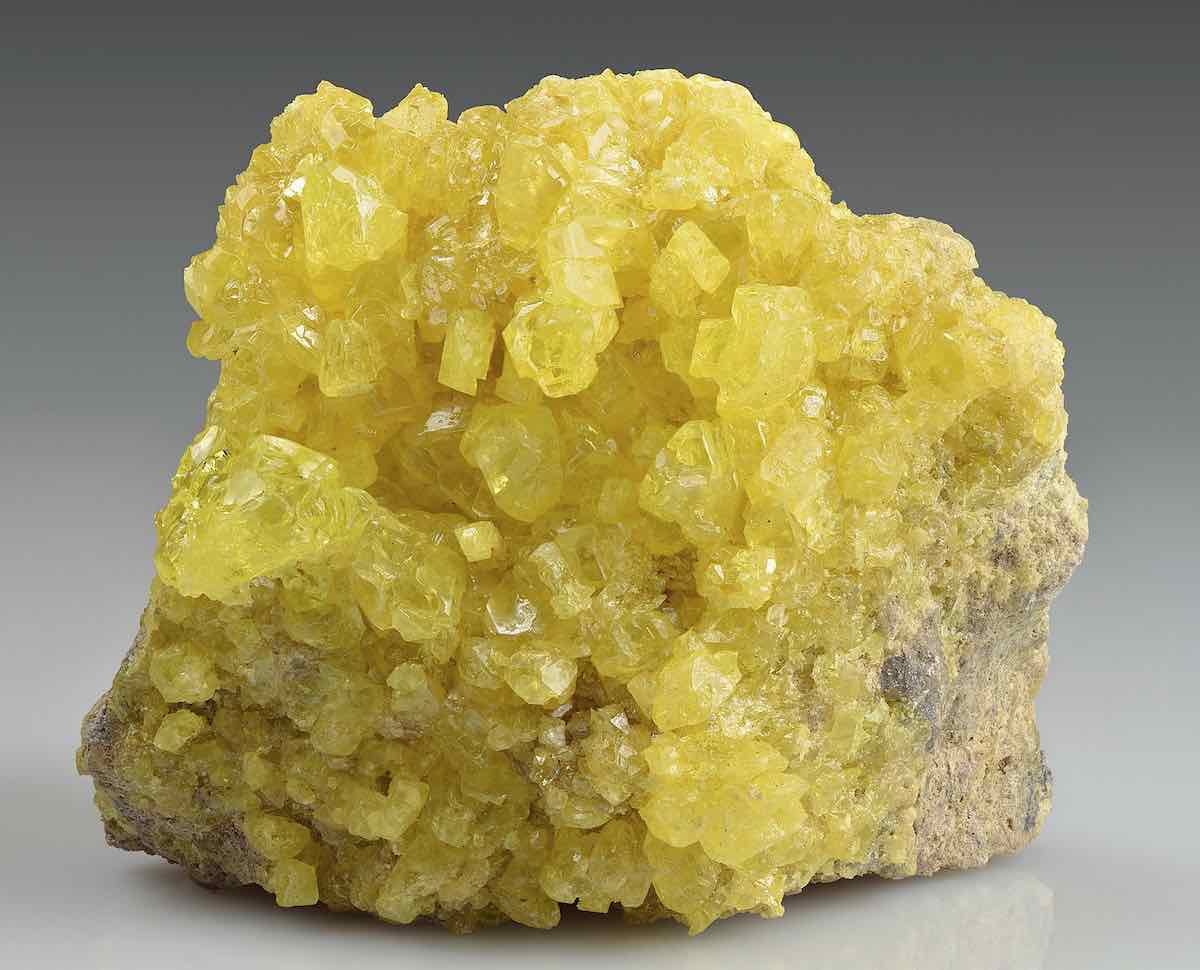

As an added bonus, lithium-sulfur batteries have no need for metals like cobalt, nickel and manganese, which are critical minerals found in most current lithium-ion batteries.

As the researchers explain, these metals are dwindling in supply globally and are often mined in places with high sovereign risk, whereas sulfur is in abundant supply in Australia, usually as a waste or by-product.

“These batteries are not dependent on minerals that are going to lack supply as the electrification revolution proceeds, so this is another step towards cheaper, cleaner and higher performing batteries that could be made within Australia,” said Professor Hill.

The breakthrough in lithium-sulfur battery technology is the second this month, with another – this time based out of Philadelphia’s Drexel University in the US – claiming to have developed a commercially viable way of producing Li-S batteries with three times the capacity of Li-ion batteries and able to last more than 4,000 cycles.