Opinions and myths are flowing freely around pumped-hydro storage.

In the interests of informed debate, we asked three experts to explain how pumped-hydro storage technology works, where it’s already operating and — as more and more renewables come into our energy mix — how it can help to ensure the nation’s reliable and secure transition to emissions-free power generation.

The experts are all from GE, the world’s biggest player in pumped-hydro storage, with 48GW of installed assets operating and another 4.7GW under construction.

Our brains trust is: David Havard, Advanced Offering Leader, Hydro Product Managementfor GE Renewable Energy, Maryse François, Hydro technology Technical Lead for GE Renewable Energy and Martin Kennedy, Head of Hydro Power sales for GE ANZ.

How does pumped-hydro storage work as part of the electricity system?

“We used to have an energy-production system largely based on gas, coal and some hydro, which was predictable generation,” says Maryse François. “With more solar and wind generation, which is not so predictable, we need more flexibility.

That’s where pumped-hydro storageis so important, because it can store energy at the grid scale. For pumped-hydro storage, you need two reservoirs with a significant height difference; water flows down from the top reservoir to the lower reservoir generating electricity by spinning the turbines.

If there is more energy being produced than is required by the grid at that time, it uses that energy to pump the water back up to the top reservoir, and it sits there waiting to generate power through the turbines again when it’s needed.” Hence the widely used term ‘pumped hydro’, though ‘hydro storage’ more accurately reflects the technology’s benefit.

How can pumped-hydro storage help with renewable-energy integration to the grid?

“Electricity is quite tough to manage, because on the grid demand has got to constantly equal supply,” explains David Havard. “When we’ve got the sun and the wind generating energy, it’s not always easy to know exactly how much you’ll produce, and so you need to be able to balance it to keep it equal to demand.

There are various ways of balancing: you can use fossil fuels, conventional hydroelectricity and now batteries, too. Sometimes, energy systems have to be curtailed because the network simply can’t take any more, and you might have to shut wind down or turn solar off.

The big difference with hydro is its storage capabilities. You can then allow wind and solar to continue to produce and use the surplus to take that water uphill and store it for when you need it later.”

What are the latest advances in pumped-hydro storage technology?

“The latest innovations mean it is very efficient and very flexible,” says Maryse François. Variable-speed technologyis key to this, enabling 100 per cent of the available excess energy to be used in pump mode.

Fixed-speed systems can only run at full capacity, so if there are three 100MW pumps receiving 270MW of surplus energy production, only two pumps will start, ‘recharging’ the upper reservoir with 200MW and leaving 70MW unused.

Variable-speed technology means all three pumps will run, adapting their speed to store precisely 270MW, integrating that surplus renewable energy to the grid when it’s needed later.

“It’s so important, and we are working all the time to target ways to make the system more complementary to wind and solar, to create completely green energy, and it will get even more flexible,” says François.

Where is pumped-hydro storage operating around the world?

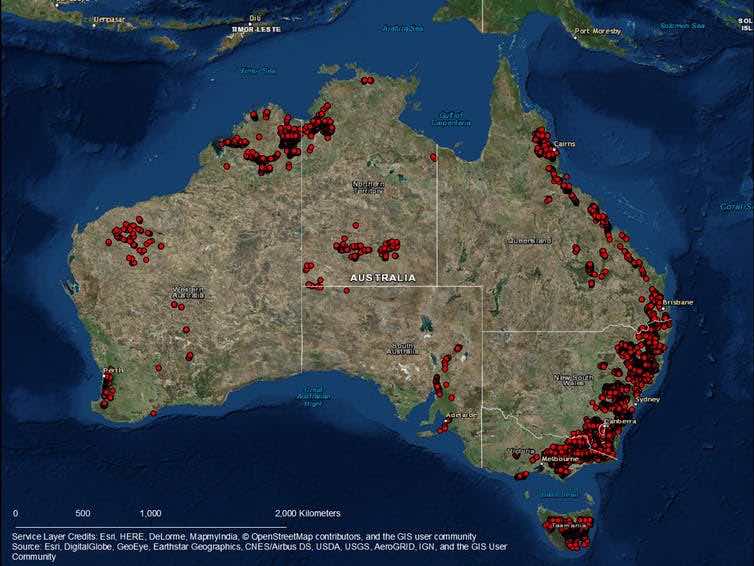

Says Martin Kennedy: “Globally, there is about 130GW of installed pumped-hydro storage capacity. What we see overseas, and what is increasingly understood in the research locally, is that once penetration of intermittent renewables gets close to 50%, there is a strong case for large-scale storage to help balance the grid.

Of utility-scale connected storage, pumped-hydro storage represents more than 95 percent of the world’s installed capacity. GE has pumped-hydro storage in Switzerland, stabilising wind in Germany and solar in Spain, in Portugal on the fringe of the European grid where there’s a high penetration of renewables, in Israel and of course China, which is putting in more renewables than any country in the world at the moment. They’re building an enormous amount of hydro capacity in that market.”

Pumped-hydro storage is often referred to as a ‘natural battery’, but aren’t we moving to actual batteries?

“Think of batteries as being like cars, and hydro storage like trucks,” says Martin Kennedy. “Just as a functioning transport system needs both cars and trucks, the same is true for the energy system: Batteries and pumped-hydro storage are complementary, they provide fundamentally different things, in fundamentally different ways.

When you need to move large amounts of generation, quickly, for large periods of time,at the lowest possible cost, and with the smaller possible relative footprint, that’s where pumped-hydro storage fits in.”

What’s the lifespan of a pumped-hydro storage project?

“If you’re looking for a five-year payback, obviously hydro storage can’t do it, we are on a different scale,” says David Havard. “You’ve got civil works — dams and tunnels — and they last at least 90 to 100 years.

You put new machines in at the beginning and they run for 40-50 years before you need to replace some components — and then you’re good again for another 50 years. So after 80 years or more, you’ve got a lot of residual value in a hydro facility, whereas batteries have to be replaced every 10-15 years.

Calculations typically look at a levelised cost of storage over 10 years or 20 years, so we need to find a fairer way of evaluating it for pumped-hydro storage. You can get a pretty quick return on investment with batteries and an attractive levelised cost of storage if you assume that a big hydro power plant has to pay itself back over 15 years or 20 years.

But you need to look at a 25-30 year payback, and at the end of that time you’ve still got a lot of value in the asset. You’ve got to regard the overall value of a pumped-hydro storage project as a long-term asset to the grid.”

What about the environmental impact of building pumped-hydro storage ?

Kennedy points to Linth-Limmern project in Switzerland.

“Switzerland is a very environmentally conscious place and the management of spoil was consequently a key issue on our projects there. One of the ways they dealt with this was to use the spoil to produce the aggregate for their concrete, effectively putting as much of the spoil as possible back where it had come from.”

As David Havard points out, projects around the world have shown that spoil can be managed and environmental footprint minimised. “And because pumped-hydro storage allows the grid to absorb more renewables, it helps keep ‘green energy’ truly green.”

This is part of an Introduction to Pumped Hydro series sponsored by GE. Another four articles will be published in coming weeks. Find also our special Energy Insiders podcast on The Future of Pumped Hydro with ANU’s Andrew Blakers and GE’s Bill Armstrong.