A molten silicon energy storage system is being touted as another possible – and much cheaper – contender for grid-scale storage of renewable energy, in the ongoing research quest to move beyond lithium-ion batteries to support solar and wind dominated grids.

A team of engineers from the Massachusetts Institute of Technology say they have come up with a conceptual design for a molten silicon-based system to store excess renewables, and deliver it back to the grid on demand, using large tanks of white-hot molten silicon and specially designed heat resistant pumps.

The tanks, which the researchers say could be designed to “power a small city” around the clock, would store heat generated by excess solar and wind power and then convert the light from the glowing metal back into electricity when needed.

The MIT team has estimated that such a system would be vastly more affordable than lithium-ion batteries, and even about half the cost of pumped hydro storage, which is currently considered to be the cheapest form of grid-scale energy storage.

“Even if we wanted to run the grid on renewables right now we couldn’t, because you’d need fossil-fueled turbines to make up for the fact that the renewable supply cannot be dispatched on demand,” says Asegun Henry, the Robert N. Noyce Career Development Associate Professor in the Department of Mechanical Engineering.

“We’re developing a new technology that, if successful, would solve this most important and critical problem in energy and climate change, namely, the storage problem.”

The storage system is only at the design phase yet – a design that has been published in the journal Energy and Environmental Science – but stems from a project based on increasing the efficiency of concentrated solar power.

Most commonly, this sort of technology is used to focus sunlight onto a central tower, where the light is converted into heat that is stored in (usually) molten salt, and eventually turned into electricity. It’s the basis of SolarReserve’s Aurora solar tower power plant being built in Port Augusta South Australia.

“This technology has been around for a while, but the thinking has been that its cost will never get low enough to compete with natural gas,” Henry says.

“So there was a push to operate at much higher temperatures, so you could use a more efficient heat engine and get the cost down.”

To do this, the MIT team looked beyond salt, which at very high temperatures would corrode the stainless steel tanks that store it.

What they eventually settled on was silicon, which as well as being one of the most abundant elements on earth, can withstand incredibly high temperatures of over 4,000 degrees Fahrenheit.

It is the same line of thinking that led to the formation of Adelaide-based company 1414 Degrees, which in May of this year lodged a prospectus for an Initial Public Offering (IPO) with the Australian Securities and Investments Commission (ASIC), after one decade and $15 million-worth of developing its own version of silicon storage technology.

The MIT team’s recent momentum, however, is based on the development of a pump it says can withstand 4000°F temperatures, and could conceivably pump liquid silicon through a renewable storage system.

According to MIT News, the pump has the highest heat tolerance on record, and is the basis of the team’s newly published molten silicon energy storage system design.

The system, which they call TEGS-MPV, for Thermal Energy Grid Storage-Multi-Junction Photovoltaics, proposes converting electricity generated by any renewable source into thermal energy, via joule heating — a process by which an electric current passes through a heating element.

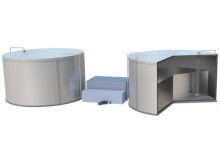

The system would work using heavily insulated, 10-meter-wide tanks made from graphite and filled with liquid silicon, kept at a “cold” temperature of almost 3,500 degrees Fahrenheit.This would be connected to. “hot tank” by a series of tubes exposed to heating elements, powered by excess renewable electricity.

Liquid silicon is pumped out of the cold tank, through the heated tubes, and into the hot tank, where the thermal energy is stored at a much higher temperature of about 4,300 F.

When electricity is needed, the hot “glowing white” liquid silicon is pumped through another bunch of tubes that emit that light, the MIT article explains.

Then, specialised “multijunction photovoltaic” solar cells convert the light into electricity for use on the grid. Meanwhile, the now-cooled silicon is pumped back into the cold tank until the next round of storage — acting effectively as a large rechargeable battery.

“One of the affectionate names people have started calling our concept, is ‘sun in a box,’ which was coined by my colleague Shannon Yee at Georgia Tech,” Henry says. “It’s basically an extremely intense light source that’s all contained in a box that traps the heat.”

It is also “geographically unlimited,” he says, and cheaper than pumped hydro, “which is very exciting,” Henry says. “In theory, this is the linchpin to enabling renewable energy to power the entire grid.”