“Hey ho, Hey ho, its off to work we go,

we shall not take our bag and stick,

hey ho, hey ho, hey ho”

Snow White and the seven dwarfs

Renewables for energy, gas for firming

In this note, a follow on from yesterday’s analysis of the costs of keeping Liddell coal fired power station open we sketch out a “transitional” renewables plant that will have an average output of 1.1GW, a minimum output of 650MW and is largely renewables based.

It’s only transitional because we use carbon emitting, expensive gas combined cycle plant to firm up the output. Even so, on our estimates the carbon intensity of the entire system is just .11 tCO2/MWh – a big improvement on Liddell (nearly 1.0tCO2/MWh – and probably at lower cost.

We very, very roughly estimate this system with 1GW dispatchable ouput and 1.1GW average output would need a price in the order of $90/MWh.

We think recent reductions in renewables costs, the increases in the price of gas and coal make this an entirely economically realistic proposition. The news service Coalwire today carries news that the world’s 4th largest reinsurer will basically no longer offer reinsurance for new coal or lignite plants.

NSW, a net electricity importer, a state where residential and community opposition to new gas and coal fields is very obvious, as are legal restrictions, nevertheless has a clapped-out fleet of coal generators and is badly in need of new power.

The answers are right in front of us and we just need politicians to get out of the way and get on the bus. Time is money and time is short, let’s get on with it.

NEM Review is the only tool, Windlab provides the inspiration

Without NEM Review’s data and database tools this work would not be possible for a tiny operation like ITK. Thanks guys. Windlab’s Kennedy Energy Park proposal provided the inspiration.

The numbers and the model presented below are at best a “sketch” and not a plan.

No account is made of bidding strategies and in fact a fixed real price is assumed. We do think the results provide some useful insights into how NSW might go about replacing Liddell and one way to think about the Generator Reliability Obligation.

Methodology, wind, pv, gas and battery

Over the past 12 months there has basically been 554MW of wind capacity operating in NSW. This has increased very recently due to the startup of White Rock wind farm but we have adjusted for that.

Thanks to NEM Review we can use the half hourly output from NSW wind over the past 12 months and scale it up (by a factor of 3) to move from 554MW to 1.6GW.

At this point we note that the last 12 months has been a relatively low wind output year, but we expect new build to have slightly higher capacity factors. So this gives us the half hourly output for a 1.6GW windfarm.

Similarly we can use half hourly output from the Moree single axis tracking plant 56 MW/AC and scale that up by a factor of 8 to give 448 MW of PV.

We didn’t put much time into the ratio of wind to PV. We used Kennedy as a guide but observed that the correlation between the wind and PV output fell a little bit as the ratio of PV to wind increased.

Then we assume we have a 650 MW combined cycle generator that can start up instantly. In reality it takes 1 hour to get to full output, but we assume the battery with its 100 millisecond response time takes care of that, and also provides frequency control.

We believe other sources of dispatchability could be as or more economic than gas, but we know gas will work, and the overall plant CO2 output is low. Using an alternative to gas, then becomes more about economics than CO2 emissions.

We also added in a 300MW/1 hour battery at a cost of $300 million. The battery increases the 1000 MW dispatchability target from 71% of all half hours to 87%, but it adds relatively little to the cost. We think we could increase the battery size to 300 MW/ 2 hours for only a small increase in cost but did not explore this case.

Dispatch algorithm

We then set a target level of dispatchable output. We chose 1GW being broadly equivalent to Liddell’s average output. For each half hour we add the wind and the PV output together. If the total is less than 1000 MW we then use the gas generator up to its limit of 650 MW to make up the difference.

Still not enough, then the battery can run for an hour if it’s not empty. The battery can’t run if it’s empty but we assume it can be fully recharged in half an hour.

We don’t allow for power to recharge the battery or round trip losses. The intuition is that in this system those missing items won’t change the results much.

Results

A summary of the system is:

The table shows that the minimum output of the system is 650 MW and we are pretty sure we could get that to 900 MW using a bigger battery for not much difference in overall cost.

The key line in the table is the average ouput. Average output is 1.15 GW and gas average output is .33 GW, so the renewable share is about 70%.

The gas plant runs at about 50% capacity utilisation which is roughly the right level for combined cycle gas. We don’t model how many starts. We think only a modern purpose-built gas generator designed for frequent fast starts is suitable for this task.

Plants such as Pelican Point would likely not be particularly efficient.

However, your author is a financial analyst not a power engineer and I could easily be missing the point on the technical capabilities or otherwise of the gas plant.

Based on 0.4 t CO2/MWh for the gas plant the emissions intensity of the entire generator is about .11 t CO2/MWh (gas share of output 30% * carbon intensity 0.4).

Dispatchability measure

A better picture, although you need to look at it properly, of the dispatchability of the system is showing the following figure.

This is based on Windlab’s presention of the Kennedy wind-solar park project in north Queensland, except that we are using half hourly data rather than daily. The figure shows the percentage of time each component, and the total system, has an output less than X where X is the vertical scale.

So for instance, 13% of the time the total generator output is less than 1 GW. However the lowest level of output is 650 MW (when the wind and pv aren’t operating and the battery is empty). About 15% of the time the output is over 1.5 GW. We don’t show the battery for simplicity.

The generator achieves its dispatchable target of 1 GW 87% of the half hours. Demand management or a larger battery could easily take care of the missing half hours to get 100% reliability. Still, even the best coal plants have the odd forced outage. On average we expect wind utilization to improve.

An example of the generation is shown below – “Series 2” is the PV, and the time period is 6500 half hours in 2017. My copy of Excel complained and became confused when asked to do its job on this chart. Apologies.

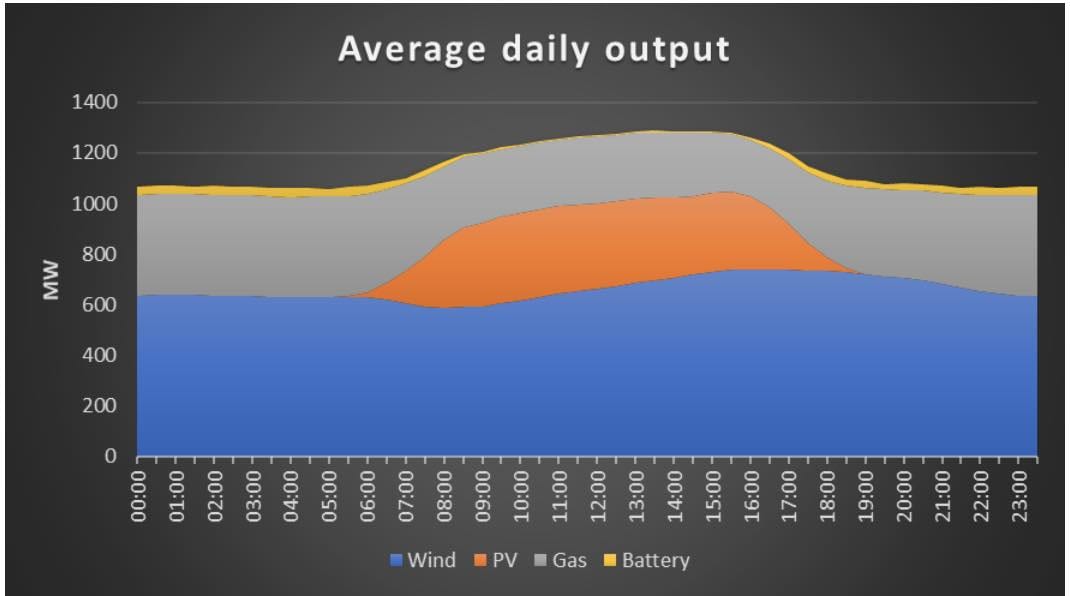

The average output by fuel over the course of an average day is shown below. The figure shows the PV reducing the gas usage on average in the middle of the day.

In practice gas is only being used if output is less than 1 GW so the averages reflect a combination of situations when wind & PV exceed the 1 GW target and when they don’t. On average the battery is used more at night.

Economics: Needs about $90/MWh. Giddy up

We estimate the system needs around $85-$95/MWh based on a gas cost of $9/GJ and after allowing for various fixed costs.

Gas consumption should be about 20 PJ per year so the fuel cost is sub $200 m ignoring transmission. In general we have ignored transmission but this is a big system.

For the sake of simplicity, and speed, we have assumed around $20/MWh of operating cost for the wind and $15/KW for PV and added in $40 million of fixed costs for good luck.

Although not cheap, if done via a Govt PPA a lower price might be possible as risk is reduced. Really, if the gas is contracted, then the only real risk is the building the gas plant, and its NSW not Victoria so even that is manageable.

The highly simplistic NPV model follows: