An unprecedented drop in renewable energy prices, the high energy intensity of mining, and the volatility of fossil fuel pricing have combined to create a ground breaking opportunity for decarbonizing the mining industry—no pun intended!

Seriously, the sustainability opportunity in front of mining companies across the world is no joking matter, and with potential to cut a gigaton of carbon, it’s time to take a hard look toward sustainable mining.

To continue economic and demographic growth as a modern society, extraction of the commodities we depend on is essential.

However, while the extractive industry has radically progressed in productivity and energy efficiency, it still remains an exceedingly energy- and carbon-intensive operation.

The amount of renewables in the mining sector’s electricity mix is only 2.5 percent of the renewable energy used globally.

Yet renewable resources have the potential to provide a large portion of the electricity consumed by the mining sector at or below the cost of traditional diesel generators or grid power.

Therefore, it is crucial to accept the existing realities of the mining industry to adopt a practical path to decarbonization.

By analyzing the mining industry, Sunshine for Mines, a Rocky Mountain Institute-Carbon War Room program, has uncovered advantages in energy economics, operational efficiency, and community relations.

In RMI’s Toward Sustainable Mining Insight Brief, we find five themes that contextualize the status of the mining industry, and provide a practical path toward a less carbon-intensive, more profitable mining operation.

- Tackling Negative Externalities in the Extractive Industry

Carbon intensity is an often-unrecognized externality of the mining industry, and is simply a consequence of the composition of the current energy mix, the off-grid nature of most mines, and the inherent energy intensity of this process.

Many mining sites in remote locations use the most readily available form of electricity generation, diesel generators, which are highly polluting and expensive.

Grid-connected mines do not escape carbon intensity either, as the electricity mix on the grid is dominated by fossil fuels.

- Energy Intensity Need Not Imply Carbon Intensity

In the cases of both off-grid and grid-connected mines, the energy load poses a significant burden on the generation and delivery infrastructure.

Some of the larger mines can reach a peak load of 250 MW. A large portion of the energy consumed at a mine site is used for material movement by diesel-operated mobile equipment.

However, conveyor belts, powered by electricity, present a possibility for efficiency and sustainability improvements. Continuing to analyze energy use on mine sites reveals immediate sustainability and efficiency improvements.

- How Energy Economics Makes This Possible

The lifetime cost of energy generated by today’s solar PV is now far lower than the cost of diesel generation, meaning an off-grid facility can operate at lower cost with solar than diesel generation.

Even assuming nighttime use of fossil fuels, there will still be an overall reduction in carbon intensity and costs.

Mining operators can lock in prices at cost-competitive rates via on-site generation or long-term power purchase agreements (PPAs) for as long as 25 years.

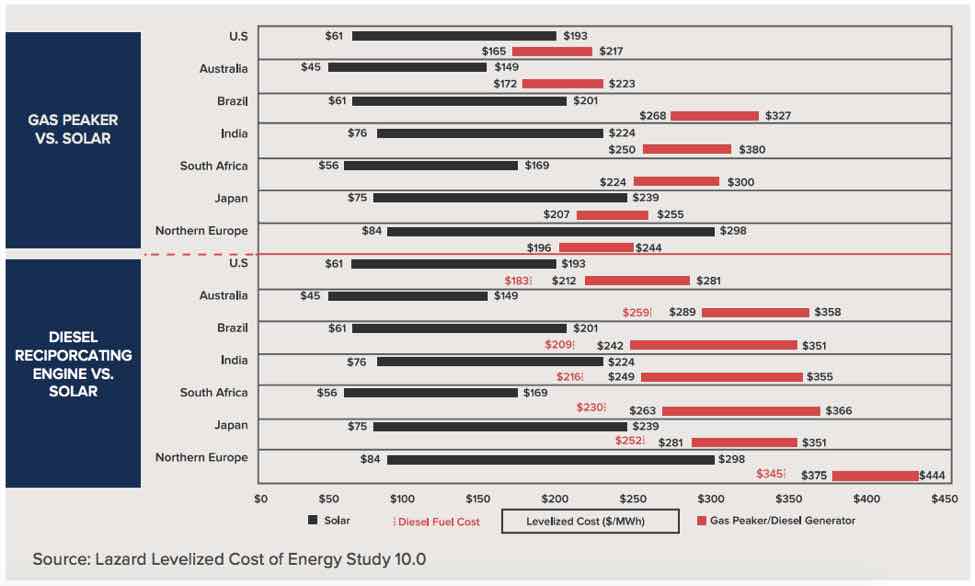

Lazard compared the levelized cost of electricity (LCOE) for solar, gas peaking, and diesel generation found at remote, off-grid mining sites, and exposed significant advantages for renewable generation:

- Driving Systemic Change

Volatility in fossil fuel prices directly impacts both grid-connected and off-grid mines, the latter relying solely on diesel generators to meet their electricity needs.

An on-site renewable energy and storage system creates supply stability and insulation from fossil fuel price spikes that plague grid-connected and off-grid mines.

Also, the large amount of available space on mining sites creates an additional opportunity for a grid-connected mine site to have an oversized system to cover its own energy production with the added benefit of selling electricity back into the grid.

- Accounting for Less Tangible Benefits

Additional benefits to the local and international communities create support for a mine’s social license to operate.

Creating Shared Value: Publicly investing in sustainability creates additional jobs for local communities in addition to creating value for the mining company.

Having 20–40 percent of a mine’s energy demand met with renewables would yield significant benefits for the local community.

Improving Community Relations: The initial investment in renewable energy has a public relations value while also creating the possibility of community integration of renewables and other technologies.

The microgrid and community solar markets are rapidly growing, allowing local citizens to buy into sustainability efforts. Aligning business efforts with community interests helps build community support for the mine.

Mitigating Climate Risks: Investments in renewable energy benefit national governments with international commitments to sustainability, allowing mining-heavy nations to lead the decarbonization efforts.

A transition to a renewables-fueled mining industry would be significant both nationally and globally.

Creating Value Out of Closed Mines: Mines don’t need to be operating for value generation via energy production.

Renewable energy and storage systems can help legacy or inactive mine sites generate revenue, reduce greenhouse gas emissions, and offer a sustainable energy solution for neighboring communities.

The Sunshine for Mines program facilitates adoption of renewables for mines and hopes to reach a total of 8 GW of renewable capacity in the ground by 2025.

By consulting with existing mines through feasibility and procurement stages and repurposing legacy mines into renewable energy generating facilities, we are certain we will reach our goal.

Source: RMI. Reproduced with permission.