A new Silicon Valley developer of thin film solar PV modules, backed by an Australian venture capitalist, has claimed an engineering breakthrough that could cut the manufacturing costs of PV modules by one third.

RSI has broken cover after five years of development to announce it has created a 1.5 square metre cadmium telluride PV (CdTe) module, twice the size of conventional modules.

It says this will enable solar PV modules to be manufactured at a cost of less than 40c/Watt, around one third cheaper than current mass-produced thin film and silicon based modules – and hastening the charge towards grid parity for solar PV.

First Solar, currently the world’s largest thin film solar PV module manufacturer, had predicted reaching 40c/W by 2017 through increases in efficiency. RSI says it can deliver that cost in 2014 by doubling the size of the module through a process known as Rapid Efficient Electroplating on Large- areas (REEL).

The company is backed by a group of venture capital firms, including the CalCEF Clean Energy Angel Fund co-managed by Australian Paul Fox, as well as Silicon Valley powerhouse Mayfield Fund, greentech VC specialist Nth Power, and Vancouver-based Pangaea.

Fox told RenewEconomy that the technology breakthrough would hasten the march towards grid parity for solar PV.

“The significance is that we can now deliver 40c/W, and will do so in 2014. People didn’t expect that to happen until 2017. This is a real acceleration. It is a step change in cost structure of PV. We are heading owards wholesale grid parity several years earlier than expected.”

The next step for the firm is to strike licensee exclusive agreements with manufacturers in each major region of the world. The plan is for the first production to take place in 2014.

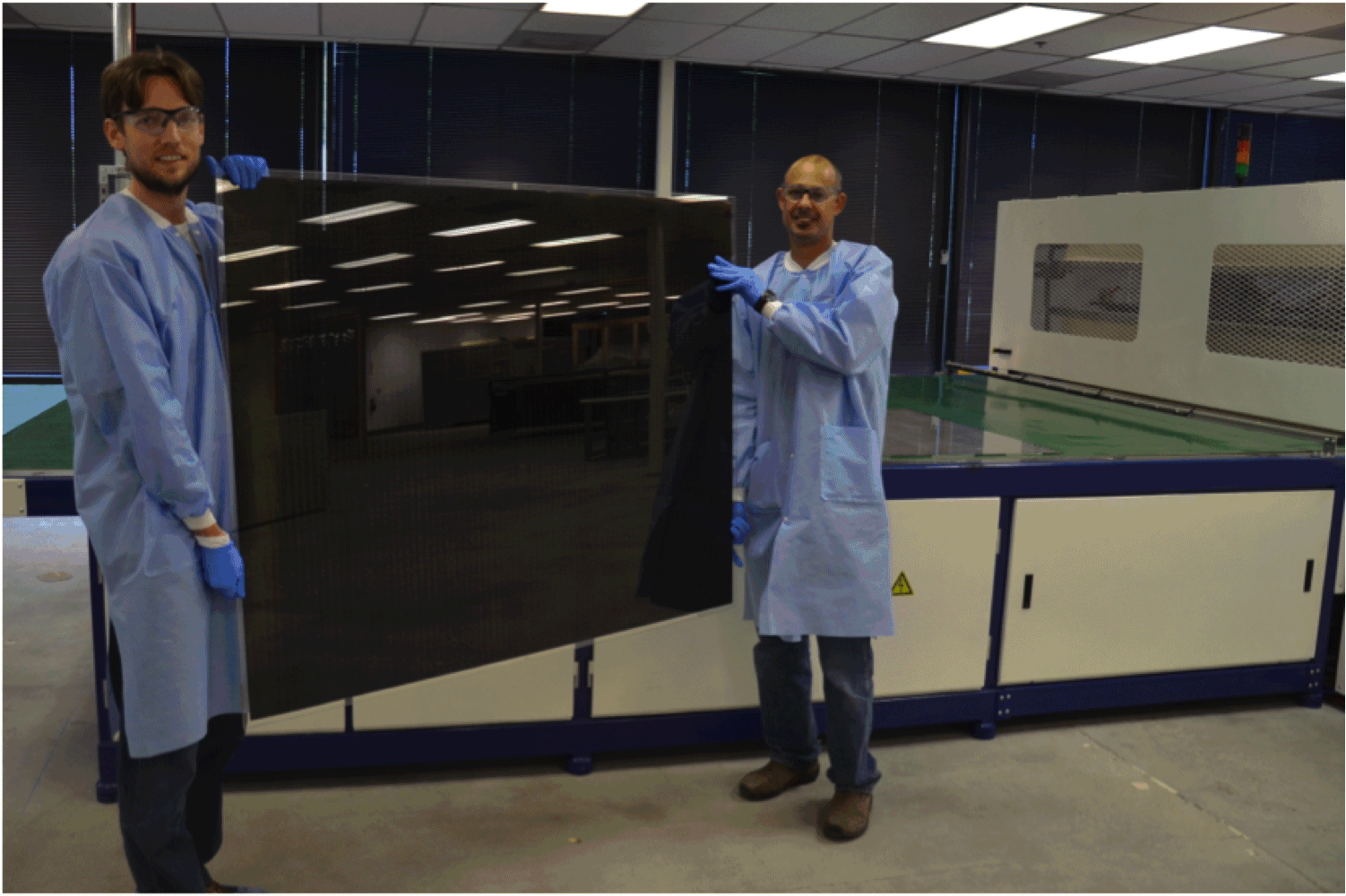

According to RSI, the size of CdTe modules (pictured) has been limited by the use of high temperature CdTe deposition processes. RSI says the REEL process speeds the plating step and eliminates constraints on panel area.

“The math is simple for large-area modules”, said RSI Co-founder and President Kurt Weiner. “At each step in the manufacturing process we are moving more Watts for a given capex, materials and labor cost.

“At the end, our panels produce significantly more power so they’re cheaper to install.

“When we founded the company we recognized that in thin-film, you needed larger panel sizes with higher power outputs, in addition to efficiency, to truly differentiate against silicon. We’ve achieved both at RSI.”

RSI CEO Ed Grady said incremental improvements to “undifferentiated technology” like crystalline silicon are not enough to prosper in this commoditised market.

“Manufacturers end up giving away their margin to survive,” he said. “First Solar has shown how to make profits through technology and cost differentiation. RSI is delivering a step change improvement in the cost structure, while retaining all the characteristics that have made CdTe so successful.”

Matt Jones, from Nth Power, said RSI had the highest potential of profit and investor return of any solar module the VC firm had seen. His optimism was shared by Pedram Mokrian from Mayfield.