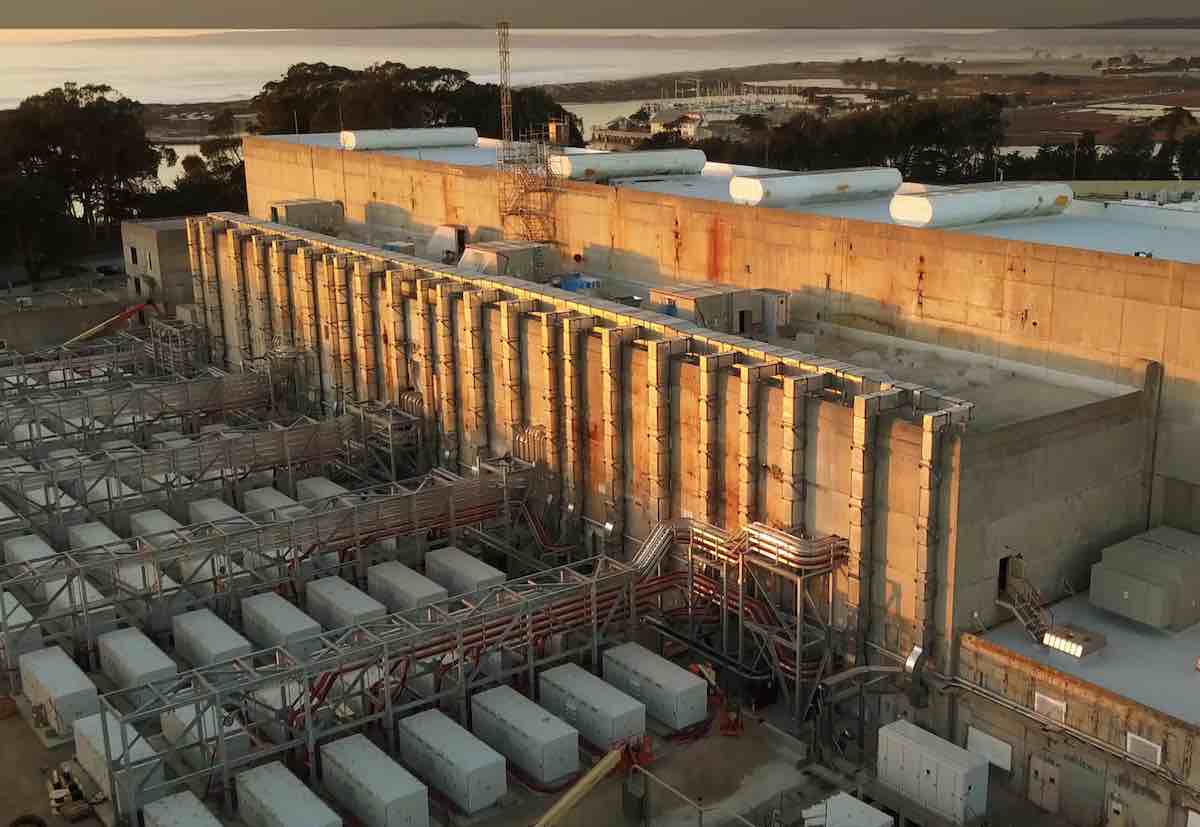

Another major problem has struck at a pioneering big battery project, this time at the 400MW/1600MWh Moss Landing Energy Storage Facility in California, south of San Francisco, which was recently expanded to become the world’s largest of its kind.

The owner and operator of the big battery, Vistra Corp, says an investigation is underway into an “overheating incident” at the Moss Landing facility, which did not result in a fire, but has taken the 300MW, four hour storage first phase of the project out of service.

“Late Saturday evening, Sept. 4, the Moss Landing Energy Storage Facility experienced an overheating issue with a limited number of battery modules in its Phase I, 300-megawatt/1200-megawatt hour system,” the statement said.

An in-built safety system had detected that the modules were operating at a temperature above operational standards and triggered a sprinkler system, bringing the overheating back under control and averting a fire, but the local fire department was called as a precaution in the record heatwave conditions of that weekend.

Vistra says it is now working alongside teams from battery manufacturer LG Energy Solution, engineering firm Fluence, and “other external experts” to gather information and begin their investigation into the root cause of the issue.

“With safety as its No. 1 priority, the company is taking a conservative approach and keeping the entire facility offline as it investigates the root cause of the incident in partnership with its engineering contractor, Fluence, and battery manufacturer, LG Energy Solution,” a statement said.

“Vistra is uncertain on the timing of the return of the facility, pending an investigation and any needed repairs. The company will update the status of Phase I Moss Landing as it learns more.

“The Phase II 100-MW system, which is located in a separate building on site, has not been affected by the event. It is currently available for operation.”

Originally announced as a two-phased 400MW/1600MWh facility, Texas-based gen-tailer Vistra was granted permission in August of last year to expand the battery energy storage system to provide up to 1,500MW, or 6,000MWh of energy storage.

The Moss Landing battery has a long term “resource adequacy” deal with Pacific Gas and Electric Company (PG&E) and had only just last month completed the 100MW second phase of the project that is being built alongside a gas-fired power plant.

The expansion was celebrated by Vistra CEO Curt Morgan, who said the four-hour battery would help fill a “reliability gap” by storing excess daytime power and sending it to the grid when needed.

But that role is now on hold until the root of the overheating problem – not to mention any damage caused by the sprinklers – is fully understood and addressed.

As a Vistra spokesperson told US website EnergyWire this week, with “more than 4,500 racks or cabinets that each contain 22 battery modules — that’s nearly 100,000 modules … and we will inspect every one of them.

“We are confident it is a matter of when, not if, the facility returns to service,” the spokesperson said. “However, speed is not our goal here — safety is.”

The Moss Landing incident lands a fresh blow to LG Energy Solution, which is in the midst of a major home battery recall in the US – and on a smaller scale in Australia, too – due to potential fire risks in its popular RESU 10H line.

The South Korean company has also been embroiled in the recall of electric vehicles that use its battery technology, including Hyundai EVs and, in the US, Chevy Bolts.

But it’s also a fresh blow to lithium-ion batteries, more broadly, and certain chemistries under that umbrella – lithium nickel manganese cobalt, in particular – that are known to be more prone to problems of overheating and thermal runaway.

Australia, of course, has had its own even more dramatic example of this in the recent fire that destroyed two Tesla Megapack containers at the Neoen-owned Victoria Big Battery in July, with still no word yet on the impact the incident has had on the commissioning of what will be Australia’s biggest battery.

As will no doubt be the case in the Moss Landing investigation, the big question for Neoen will be the cause of the fire and whether it stemmed from a manufacturing or installation or production fault.

It has not yet been made clear which battery chemistry has been used in the Victorian Megapacks, but Tesla announced earlier this year it was switching from lithium nickel manganese cobalt to LFP (lithium iron phosphate) which is said to be more fire resistant and non toxic.

As EnergyWire reports, however, the mood in the US around Moss Landing is overwhelmingly positive, buoyed by the belief that the energy storage industry – which is rapidly becoming one of the most important enabling partners to the global shift to renewables – will rise to such challenges, as well as to the costs that come with them.

“I do not think we should understate the importance of safety,” Kelsey Hatzell, an assistant professor at the Andlinger Center for Energy and the Environment at Princeton University who studies batteries, told the website. “But I am optimistic that we can engineer for safety.”

“The safety systems in place for the Moss Landing project worked as designed to notify operators of overheating,” said Jason Burwen, interim CEO of the U.S. Energy Storage Association.

“Grid operators, including California’s, expect to rely on increasing levels of energy storage to meet decarbonisation and reliability goals and we don’t see that changing because of what happened with the Moss Landing project.”