The newly expanded Hornsdale Power Reserve, aka the Tesla big battery, has reported a successful “real life” test of its new “virtual machine mode” when it reacted to the grid disturbances created by the Callide coal plant explosion in Queensland on Tuesday.

The Callide explosion, and the subsequent trip of its neighbouring units, had a cascading impact on the Queensland grid, cutting power from nearly half a million customers through the state. But it also had an impact on the rest of the grid, creating a frequency excursion that had to be addressed.

That’s where the Hornsdale Power Reserve stepped up, in what turned out to be a satisfying “real world” test of its newly expanded tool-kit that has been added since it expanded its size last year from 100MW/129MWh, to a once world-leading but still country-leading 150MW/194MWh.

These tools are variously described as “synthetic inertia” or a “virtual machine”, or “grid forming inverters”. What it is designed to do is to provide the inertia services that will slow down the rate of change of frequency that can be caused by dramatic events such as the Callide explosion.

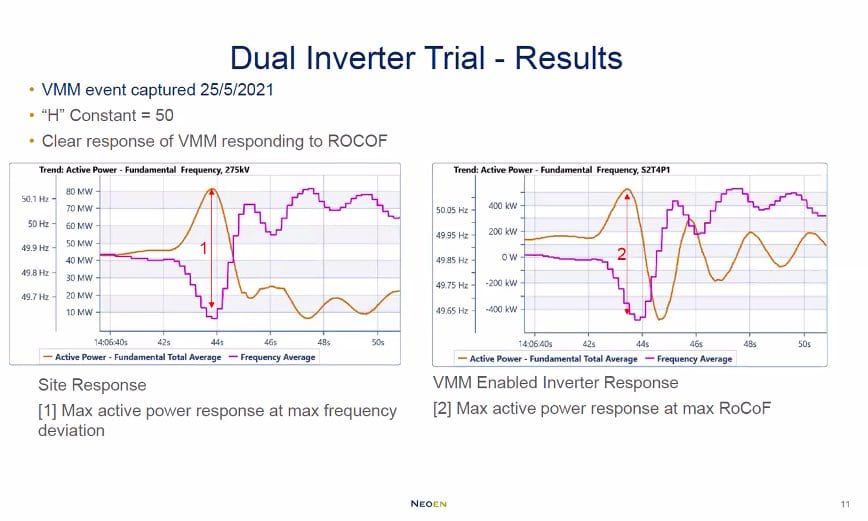

This graph above (on the left) shows how the Hornsdale battery (orange line) responded instantaneously as frequency in the grid (purple line) initially plunged to a low of 49.6 Hertz as the events in Callide cascaded and caused multiple generators to trip, and then jumped to 50.1Hz as load was lost.

It did all of this in two seconds, and that’s pretty much what Hornsdale and other big batteries are set up to do, and have been doing successfully. What’s interesting and new is the graph on the right and how the battery’s new bag of tricks responded to Tuesday’s calamitous events.

This is about delivering “inertia” and getting “in front” of the frequency curve when there is a bad event (like a big coal generator exploding and catching fire), and trying to slow down the rate of change of frequency. It’s a crucial grid service normally delivered by spinning machines, and now being trialled by batteries.

What this graph shows is that the two inverters at Hornsdale that have been enabled with “synthetic inertia” or “virtual machine mode” responded even more rapidly, and reached peak output about one third of a second before the rest of the battery.

These inverters, operating in “virtual machine mode,” detect excursions as they happen and by slowing the rate of change of frequency (ROCOF) they give the grid more time to respond.

“This shows that the virtual inertia mode hopes to catch these things even earlier,” Neoen’s Garth Heron says. “This is the future.”

That’s a bold claim, but it is what the (progressive) side of the electricity industry is now thinking: How the grid will look without synchronous machines such as coal and gas generators, and these new technologies are proof that it can be done.

Behrooz Bahrani, from Monash University, told a webinar hosted by the Australian Renewable Energy Agency on Thursday on the subject of grid forming inverters – and where the Hornsdale results were presented – that it was clear battery storage can provide inertia and “system strength”, and that grid operators need to think beyond old parameters.

“We need to go beyond synchronous generators,” Bahrani said. “We need to think what else the batteries can do and not just focus on mimicking synchronous generators.”

Sachin Goyal, from Powerlink, which has been running its own research on inverter based technologies and their abilities to solve system strength issues, agreed:

“Any inverter that connects to grid is more stable than synchronous generation. We should not be blindly following what synchronous generators can do, we should be taking the best parts and adding to them.”

Neoen’s Garth Heron says it is clear from the tests at the Hornsdale battery that inverter based technologies can deliver the same inertia responses as synchronous machines twice their size.

And he reinforced the fact that battery storage has layers upon layers of skills and services, many not recognised yet by the market. The trick is to get a control system that delivers the right response from the battery under all situations.

Tesla’s Josef Tadic, who presented the report at the webinar with Heron, said batteries can be customised for specific network conditions, and this response is provided in parallel with traditional primary frequency control, energy market dispatch, and blackstart services.

“This is a key issue the industry is working on as the market displaces traditional thermal synchronous generation and accelerates the transition to higher renewable penetration,” he said in a later LinkedIn post.

Neoen, which owns the Hornsdale battery, hopes to be rolling out the “virtual machine mode” to the rest of that battery by the end of the year, once more extensive modelling is complete to the satisfaction of the Australian Energy Market Operator.

Transgrid, meanwhile, is planning on doing the same thing as its 50/75MWh Wallgrove battery currently being built in western Sydney and which will use Tesla Megapack technology (as opposed to the smaller Powerpacks at Hornsdale).

And, in interesting news just in from Queensland, just two days after the Callide event, the state-government owned Stanwell has announced it will build a 150MW big battery next to its Tarong coal fired power stations as part of a Queensland “battery blitz.”

Neoen is also hopeful of building an even bigger battery at Western Downs, next to the 400MW solar farm it is now constructing, as well as another big battery next to the Kaban wind farm which it will build in north Queensland, despite the veto of a NAIF financing deal by resources minister Keith Pitt.