Perovskite solar cells aren’t quite at commercialisation stage yet, but scientists from Linköping University in Sweden are striving to have a functional recycling option ready to go when they are.

The researchers have found a way to use heat and water with salt and acid additives to melt a perovskite cell into its parts and then capture the critical perovskite crystals to be reused.

The process can recycle 99 per cent of their perovskite technology while also neutralising the lead ions, which are often used in these cells but are also quite toxic, said the resulting paper, published in Nature this month.

Importantly, the recycled cell averages 21 per cent efficiency and a maximum of 23.4 per cent – it’s not quite the 25 per cent industry standard but the Linköping researchers believe it’s a promising start given the cell was remade from almost exactly the same materials as its predecessor.

“We demonstrate that our recycling strategy can greatly alleviate the environmental burden of waste perovskite modules, especially for the human toxicity and resource depletion impacts, and also reduce the levelized cost of electricity,” the paper says.

“This study demonstrates unique opportunities of holistic perovskite solar module recycling—which are barely possible for other PV technologies—for a sustainable and circular solar economy in the future.”

Solar crystals

“Perovskites”, the name for crystals that can absorb light and excite electrons into making electricity, have been the next big thing in solar for many years.

They are lightweight, have a high tolerance for defects, could be made cheaply, and researchers are figuring out how to get the efficiency up past 30 per cent.

But they’re also unstable and scaling them up past small, lab testing kit size has been a big challenge.

Further to that, in an age hyperaware of the waste being caused by old PV solar panels a new technology shouldn’t be released onto the market without a viable recycling option, said study coauthor professor Feng Gao in a Linköping University article.

Australia’s PV trash pile is expected to reach the equivalent of 1.2GW of panels a year by 2030, or a cumulative 680,000 tonnes. It is an issue that even MPs now appear to be aware of as a political problem, but which is now big enough to sustain several private sector companies trying out high tech solutions.

Going green

Typically, recycling a perovskite cell currently involves solvents to split the layers of a cell.

These include industrial solvent dimethylformamide, chlorobenzene which was once used to make DDT or methylamine which is still used to make insecticides and paint removers.

The other issue is also the presence of lead in perovskite cells because it is a good conductor; methylammonium lead iodide was one of the first perovskite crystal structures used.

Instead, what the Linköping team did was use a “green” solvent which repaired and reclaimed perovskite crystals.

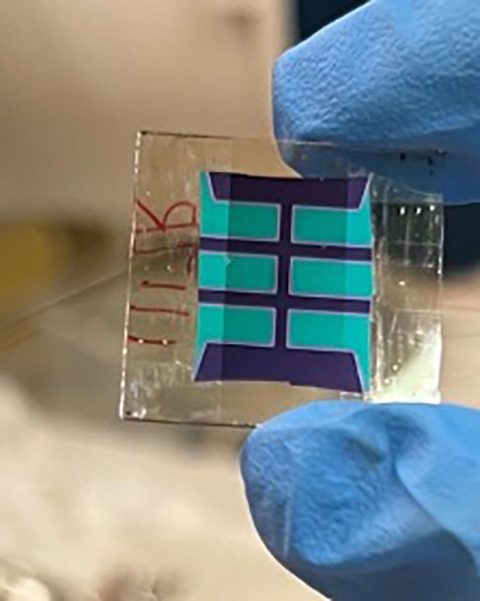

They began by heating their perovskite cell to 150°C to split the encapsulating layers – the one that keeps the crystals from being exposed to the air – away from the cell. Those layers, such as the covering glass, can then be recycled separately.

Then the crystals are dissolved in a solution of water, sodium acetate (NaOAc), sodium iodide and hypophosphorous acid. The first helps the crystals dissolve, the second allows crystals to reform and the third acts as a stabiliser.

All additives are cheap and safer to use than the usual solvents.

“Equipped with the additives, the aqueous solution is optimized to feature enhanced perovskite solubility, phase-pure crystal growth capability and excellent thermal stability,” the paper says.

“We successfully restore almost all of the essential functional materials, including hole/electron transport layers, the perovskite layer, indium tin oxide (ITO) substrates and cover glasses, with high recycling efficiency and purity.”

The next stage will be to take the process out of the lab and scale it up as an industrial process.