A new design for mammoth wind turbine blades longer than two football fields could deliver 50MW offshore wind turbines.

The research for the new wind turbine blades designs has been conducted by the Sandia National Laboratories, a multi-program laboratory operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corp., for the US Department of Energy’s National Nuclear Security Administration.

According to Sandia, it was challenged to design a low-cost offshore 50 MW turbine with wind turbine blades of more than 650 feet, or 200 meters in length.

That’s two and a half times longer than any existing wind turbine blade.

“Exascale turbines take advantage of economies of scale,” said Todd Griffith, lead blade designer on the project and technical lead for Sandia’s Offshore Wind Energy Program. Sandia has been working on wind turbine designs for a while now — including 13 MW systems using 100 meter blades, which are the basis for Sandia’s Segmented Ultralight Morphing Rotor (SUMR) designs.

50 MW wind turbines are a long way off, but according to Sandia, “studies show that load alignment can dramatically reduce peak stresses and fatigue on the rotor blades.” This would not only reduce blade costs, but eventually lead to the mythical 50 MW wind turbines.

And these developments are vital to the offshore wind industry in the US.

“The US has great offshore wind energy potential, but offshore installations are expensive, so larger turbines are needed to capture that energy at an affordable cost,” Griffith said.

“Conventional upwind blades are expensive to manufacture, deploy and maintain beyond 10-15 MW. They must be stiff, to avoid fatigue and eliminate the risk of tower strikes in strong gusts. Those stiff blades are heavy, and their mass, which is directly related to cost, becomes even more problematic at the extreme scale due to gravity loads and other changes.”

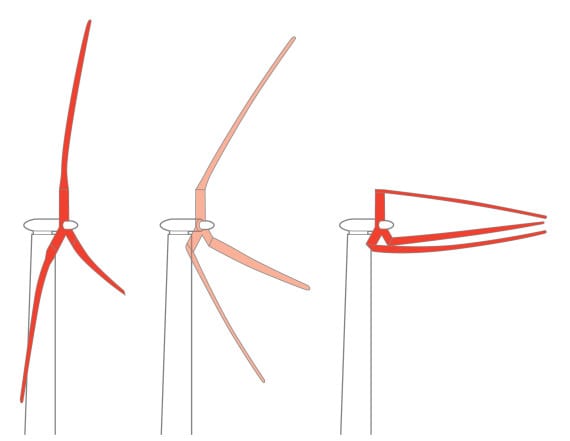

That’s where Sandia’s segmented designs come in (as seen above). Not only do they provide more cost-effective manufacturing and installation — as the blades can be manufactured in segments rather than as a massive long blade, which extends to transportation and installation as well — but, inspired by how palm trees move in storms, the blades would be positioned downwind, and the segmented sections would bend in the wind while retaining segment stiffness.

“At dangerous wind speeds, the blades are stowed and aligned with the wind direction, reducing the risk of damage,” explained Griffith. “At lower wind speeds, the blades spread out more to maximize energy production.”

Source: CleanTechnica. Reproduced with permission.