Andrew Forrest’s Fortescue Metals has announced work has commenced on its $50 million green metals project in the Pilbara, now emerging as one of the key parts of its still ambitious green hydrogen and industry plans.

Fortescue is eyeing big opportunities in the green metal supply chain, with a particular focus on the China market, and the project at its Green Energy Hub at Christmas Creek is expected to produce more than 1,500 tonnes of green metal a year, with production starting in 2025.

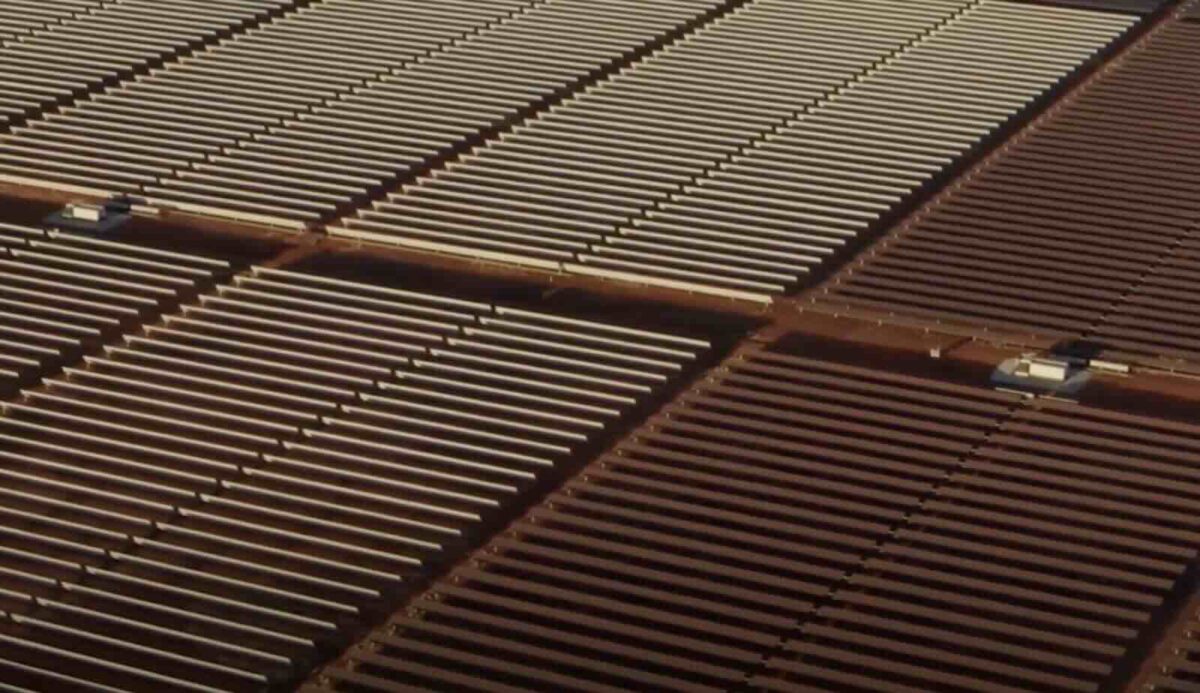

The project combines green hydrogen produced on site, courtesy of local solar power, and an electric smelting furnace to produce the high purity green metal that it says will be suitable for use in any steel plant around the world.

Located at the Green Energy Hub at Christmas Creek, the US$50 million project is expected to produce more than 1,500 tonnes per annum of green metal, with first production anticipated in 2025.

The plant will use green hydrogen produced at Fortescue’s newly completed gaseous and liquid hydrogen facility, the largest of its kind in Australia, together with an electric smelting furnace to produce high purity green metal.

Fortescue defines green metal as the processing of iron ore into iron, using renewable energy and with near zero carbon emissions.

“Today is a celebration of innovation, collaboration and stretch targets, and marks a pivotal moment in Fortescue’s journey to build a green metal supply chain,” executive chairman and major shareholder Andrew Forrest said in a statement.

“Iron and steel are the backbone of our infrastructure, however traditional iron and steel production processes are among the largest sources of greenhouse gas emissions. By rethinking the entire iron and steel value chain we can produce an entirely new, green industry here in Australia.

“Right now, we have a once in a generation opportunity to build a green supply chain, and Fortescue is wasting no time to seize it.”

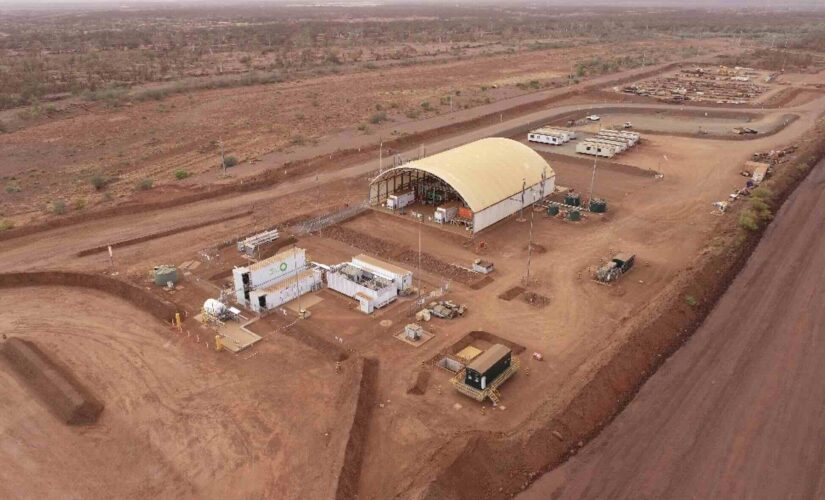

The newly commissioned green hydrogen plant at Christmas Creek will produce around 530 kilograms of green hydrogen a day, or around 195 tonnes a year with two 700 kw electrolysers.

This is just a small dot on the original global target of 15 million tonnes of hydrogen a year, which it now admits it won’t meet in that timeframe, but the company still aims to reach “real zero” emissions – which means no burning of fossil fuels – at its Pilbara operations by 2030.

The plant comprises a gaseous hydrogen refuelling station (HRS) which will refuel a fleet of 10 fuel cell electric vehicle hydrogen-powered coaches that are replacing the company’s diesel coaches. The plant also features a hydrogen liquefaction facility, liquid hydrogen storage, and a liquid-hydrogen refueling station.

The Green Energy Hub also hosts Fortescue’s prototype battery electric haul truck and a three-megawatt fast charger prototype, and its first hydrogen electric haul truck, which will begin trials soon at Christmas Creek.

“Hydrogen and fuels made using renewable energy will have a role to play in decarbonising mining, whether it’s in buses, heavy mining equipment such as haul trucks and excavators, or producing green iron,” CEO Dino Otranto said in a statement.

“This renewable hydrogen plant is versatile, enabling us to produce gaseous and liquid hydrogen to be used to power our mining equipment prototypes, while also providing the added benefit of refuelling our fleet of coaches at Christmas Creek.”

The $32 million hydrogen hub project – backed by $2 million of state funding – was designed by New Zealand-based Fabrum, in which Fortescue is a part owner, and marks the company’s entry into the mining and minerals industry to add to its work in heavy transport, aviation and other industries.

The news was welcomed WA Premier Roger Cook, who said green hydrogen will have an important role to play in remote areas like mine sites, reduce their reliance on diesel and slashing emissions on site.