State and federal energy ministers on Friday have adopted the National Hydrogen Strategy, prepared by chief scientist Alan Finkel, but serious questions remain over whether it will position Australia as a “green hydrogen” leader, as hoped by some, or if it will instead be used as another prop for the coal industry and carbon capture technology.

The COAG energy council agreed to Finkel’s vision for a multi-billion dollar “technology-neutral” hydrogen export industry, with efforts by the ACT energy minister to limit hydrogen production to only using to renewables, rejected by federal minister Angus Taylor, who chaired the meeting.

In an interview before the meeting, Taylor suggested hydrogen production should be “technology neutral”, indicating it could be down using brown coal. There are fears the strategy will be used as an excuse to prop up the economics of coal and use hydrogen as part of marketing ploy in the same league as “clean coal”.

RenewEconomy understands that efforts by ACT energy minister Shane Rattenbury to secure a commitment from COAG energy council to produce hydrogen using only renewable energy sources, were blocked by Taylor.

“It’s disappointing that other jurisdictions did not support the ACT’s proposal to amend the National Hydrogen Strategy to focus on green, renewable hydrogen,” Rattenbury said.

“Green hydrogen produced from renewable electricity, like wind and solar, is the way of the future. Green hydrogen will be in demand as countries seek zero emissions energy solutions and I will continue to advocate for green hydrogen and an end to fossil fuel extraction and use in Australia.”

Following the meeting, federal resources minister Matt Canavan said the government would be encouraging all forms of hydrogen creation, including production using brown coal.

“It’s not the time to foreclose different ways of producing hydrogen which would limit our ability to reduce those costs in the supply chain,” Canavan said.

“What we’ve adopted today is taking a technologically neutral approach. That is the recommendation of the Finkel review.”

However, ministers agreed to a recommendation of Finkel’s hydrogen strategy to introduce a ‘guarantee of origin’ scheme that will at least provide transparency around the effective emissions intensity of hydrogen produced in Australia.

“I welcome the certification standards that will be introduced for domestic and international hydrogen markets. These standards will clearly show the emissions intensity of hydrogen enabling consumers to choose zero emissions green hydrogen,” Rattenbury added.

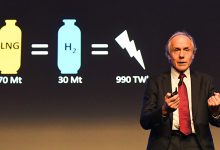

Japan and South Korea have both established targets for growing their use of hydrogen, particularly in transport and industrial uses. With the ability for hydrogen to be produced using renewable electricity, it provides a pathway to decarbonising sectors beyond the electricity sector.

“An Australian hydrogen industry could generate thousands of jobs, many of them in regional areas. It could add billions of dollars to GDP over coming decades,” the strategy says.

“There is potential for thousands of new jobs, many in regional areas – and billions of dollars in economic growth between now and 2050. We can integrate more low-cost renewable generation, reduce dependence on imported fuels, and help reduce carbon emissions in Australia and around the world.”

Ahead of the meeting, The Australia Institute said that it was important not to ‘overhype’ the potential demand from Japan and South Korea, warning that if “hydrogen development is rushed in Australia, it could see fossil fuels locked in as a global energy source for decades to come.”

Dr Finkel has recognised a strong desire within the Federal government, and some state governments, to continue exploiting Australia’s fossil fuel resources, and had canvassed an approach of exporting ‘clean’ hydrogen using brown coal, combined with carbon capture and storage technologies.

Finkel had telegraphed the idea of producing hydrogen from coal when he presented initial thoughts on a potential national strategy at the Clean Energy Summit in July, and reflects a search for a proposal that that is likely to be politically palatable.

“Australia is also well situated to take advantage of carbon capture and storage technologies to produce low-emissions hydrogen from coal and natural gas. Carbon capture is likely to be more cost-effective for hydrogen production than for electricity generation,” the strategy says.

The use of coal in hydrogen production won the endorsement of federal energy minister Angus Taylor ahead of the meeting, agreeing that Australia needed to apply a ‘technology-neutral’ approach.

“Well, from the start, this strategy work has been focused on a technology-neutral approach. Its says, look, there can be many different fuel sources to produce hydrogen,” Taylor told ABC’s RN breakfast program.

“We want it to be technology-neutral. That’s been the approach that Alan Finkel has taken from the start and whilst it is not going to happen overnight, we do think there’s enormous potential here.”

Still, many projects, including the massive 15GW Asia Renewable Energy Hub in the Pilbara backed by the Macquarie Group, are focused on renewable hydrogen.

The idea of emissions intensity certification was welcomed by environmental and energy law expert, Dr James Prest from the Australian National University, as a way to distinguish renewable hydrogen from hydrogen produced using fossil fuels.

“Australia can sell renewable hydrogen to the world and command a premium price from green buyers – but only if it takes the steps necessary to set up a Guarantee of Origin scheme,” Prest said.

“The National Hydrogen Strategy has set out the steps for such a Scheme. What’s needed is to implement, not ignore the recommendations of the Strategy. The Federal Parliament can make laws to implement this scheme consistent with leading international approaches.”

Director of the Centre for Climate and Energy Policy at the Australian University, professor Frank Jotzo, also warned that while it might be cheaper to produce hydrogen from brown coal in the short term, it would ultimately lead to increases in Australia’s emissions in the long run.

“A looming question is whether hydrogen would be made using solar and wind power, or on the basis of brown coal. Even with carbon capture and storage, brown hydrogen would have significant remaining emissions. That process is likely cheaper at the start,” Jotzo said.

“But it would bump up Australia’s emissions, and it could mean stranded assets when emissions constraints bite, and if importers shun coal-based hydrogen in future.”

Think tank The Australia Institute has pointed to the poor track record of carbon capture and storage projects to deliver on the promises of the technology, in a new report timed to coincide with the COAG energy council meeting.

“A decade ago, the fossil fuel industry promoted clean coal using CCS, and now it is promoting hydrogen using the same unsuccessful technology. CCS projects have repeatedly failed to live up to promises, both domestically and globally, and missed their targets by a very large margin time and time again,” The Australia Institute’s climate and energy program director Richie Merzian said.

“The only way to make hydrogen truly sustainable is to produce it using water and powered by renewable energy sources. Australia has time to establish and lead a global renewable hydrogen industry and should focus research and development efforts in that area exclusively.”

In one shocking example, the federal and Victorian governments gave promises of support to a brown-coal gasification process in the Latrobe Valley. The $500 million project was expected to deliver just 3 tonnes of hydrogen gas across its 12 months of operation.

Others, including ARENA CEO Darren Miller, have advocated for the construction of large-scale wind and solar projects as a better approach to achieving cost-competitive hydrogen production using zero-emissions energy.

Hydrogen has the potential to provide a zero-emissions source of energy for many industrial processes that require large amounts of heat. Earlier this month, German steel giant Thyssenkrupp successfully undertook a trial using hydrogen in its blast furnaces, a potential first step towards substantially reducing the amount of coal needed in the steel production process.