Recent revisions to my steel demand projections through 2100 have changed how I view the viability of new steelmaking technologies. Global demand for primary steel is flattening and I expect it to fall globally, largely because China’s cement and construction boom is winding down.

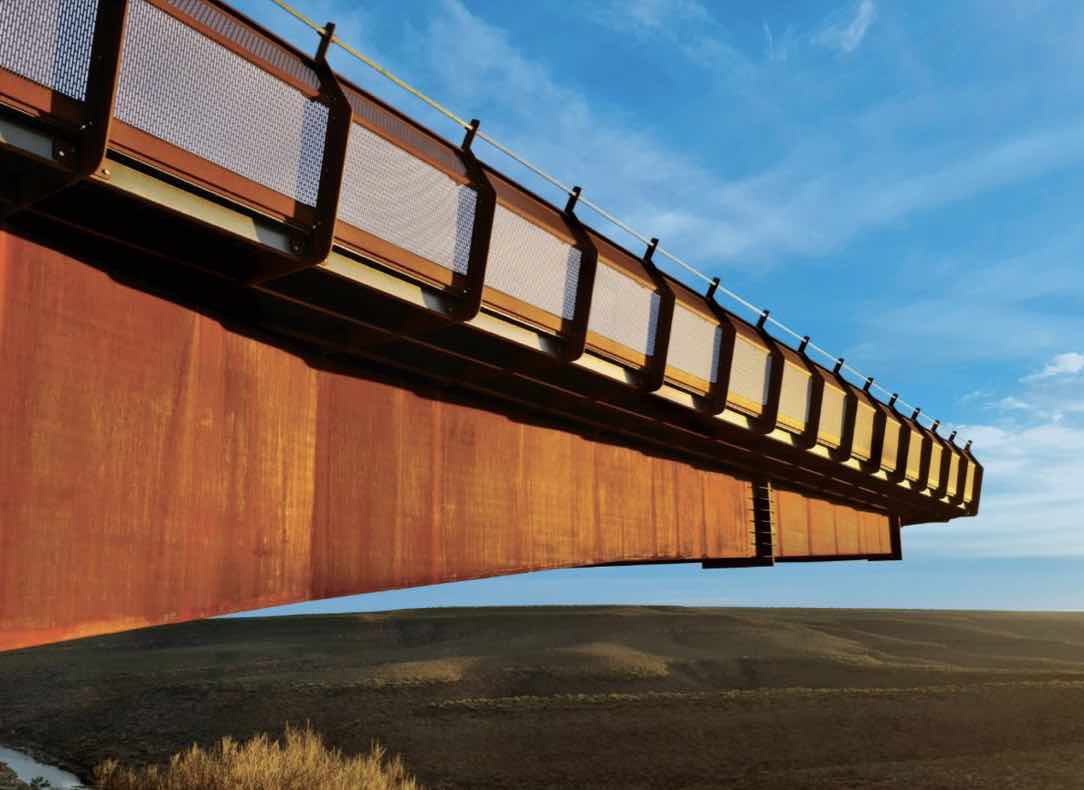

This means fewer new bridges, fewer new skyscrapers, and a long-term shift in the steel-cement relationship that has underpinned growth in primary steel production for decades.

With fewer tonnes of steel to produce, the margin for error in industrial investments shrinks. Capital misallocations and inefficient processes become more visible.

Fig 1: projection of steel demand met by scrap and some DRI technology by author

As I noted recently in these pages, Australia sits in a uniquely favourable position in this new steel landscape. It has vast iron ore reserves, some of the cheapest renewable electricity potential on the planet, reasonable access to natural gas, and viable carbon sequestration geology.

These factors do not point to a one-size-fits-all solution. Instead, they suggest three different steelmaking pathways will fit different regions and use cases within Australia.

None of them is hydrogen-based direct reduction of iron (DRI).

Over the past five years, hydrogen has been heavily promoted as the future of green steel. The idea was straightforward: produce hydrogen from renewable electricity using electrolysis, feed that hydrogen into a shaft furnace, reduce iron ore into solid metal, and melt the result in an electric arc furnace. It was pitched as clean, flexible, and technically proven. It is technically proven.

But the economic assumptions that supported this vision have not held up. Electrolyzer costs remain high. Hydrogen production efficiency remains low. Compression, storage, and distribution remain complex and costly.

Electricity is cheap in Australia compared to global averages, but not cheap enough to make green hydrogen anywhere near $2 per kilogram, let alone the $1.50 or lower required for cost parity with other options.

The reality – even where remote industrial facilities combine wind, solar and storage to firm electricity – is $3 to $4 per kilogram in Australia, and $5 to $8 in most of the developed world.

Hydrogen DRI only works on a spreadsheet if you assume energy prices from a future that has not arrived and may never fully materialize. That gap between expectation and reality matters.

Australia does have a credible zero-carbon steel opportunity, but it does not revolve around hydrogen. It rests on three different processes, each suited to a different industrial geography and resource mix.

In places with abundant renewable electricity, particularly large swaths of interior Queensland, northern South Australia, and the Pilbara where wind and solar can be co-located at scale, molten oxide electrolysis makes the most sense.

MOE is a direct electrification route. It bypasses hydrogen entirely and splits iron ore electrochemically into liquid iron and oxygen. The only inputs are electricity and iron ore. There are no carbon emissions at the site. The process has been proven at pilot scale by Boston Metal, and the company is building toward commercial demonstrations.

At four megawatt-hours per ton of steel, MOE is energy intensive, but Australia’s renewables can support that. With electricity at $0.03 per kilowatt-hour, that is $120 per ton in power costs. Add another $50 for capex amortization and operating expenses, and MOE can deliver liquid iron at about $170 per ton in places with abundant, low-cost renewables.

That is lower than flash ironmaking, lower than biomethane DRI, and much lower than hydrogen DRI. MOE also eliminates the need for hydrogen infrastructure, gas pipelines, or high-pressure tanks. It is modular, electrically driven, and well suited to new-build industrial projects next to solar and wind resources.

Fig 2: ChatGPT-generated map of Australia highlighting region-specific zero-carbon steelmaking pathways: MOE in renewable-rich zones, flash in gas basins, and biomethane DRI in agri-industrial regions.

In regions where natural gas is cheap and carbon sequestration geology is accessible, flash ironmaking becomes economically interesting. This process rapidly heats fine iron ore particles using oxygen and a combusted fuel, traditionally natural gas.

The reactor is compact and does not require sintering or pelletization. It operates continuously and can produce liquid iron or direct reduced iron depending on configuration. If paired with carbon capture and storage, it can deliver steel with emissions comparable to MOE.

Australia’s geology supports this. The Cooper Basin and the Gorgon CO₂ project off Western Australia are evidence that CCS is feasible here. With natural gas priced at $6 per gigajoule, and assuming five gigajoules per ton of steel, that is $30 in fuel. Add $50 for capex and operations, $30 to $50 for CO₂ capture and compression, and another $10 to $20 for residual carbon pricing, and you are still under $200 per ton.

Flash reactors also benefit from quicker start-stop capability than blast furnaces, meaning they may offer grid flexibility benefits. The only downside is reliance on fossil gas, but in places where CCS is cheap and permitted, that is not a deal-breaker. Flash iron-making offers an option for Australia to transition away from blast furnaces without waiting for MOE to scale or relying on expensive hydrogen.

The third viable pathway is electrified biomethane-based DRI, paired with CCS. This is not a universal solution, but it fits well in specific regions. Where waste biomass is abundant and landfill methane is an issue, producing biomethane from anaerobic digestion or thermal gasification becomes attractive. If that biomethane is burned in a shaft furnace to reduce iron ore, and the resulting CO₂ is captured and sequestered, the process achieves negative emissions. That is valuable.

With carbon priced at $100 per ton and negative emissions creditable, the economics become compelling. Biomethane costs around $20 per gigajoule. A DRI process might need 7 gigajoules per ton. That is $140 in fuel. Add $50 in electricity for heating and melting, $100 in capture costs, and subtract $100 for the negative CO₂ credit. The resulting cost is around $190 per ton.

In locations like northern New South Wales or parts of Victoria where agriculture produces large volumes of organic waste and where offshore CO₂ pipelines are possible, this process can produce steel at a competitive cost while sequestering carbon. It will not scale globally, but for Australia’s domestic needs and select export products, it fits.

Hydrogen DRI does not fit. Even with generous assumptions, the cost per ton remains above $300, often closer to $500. That is before accounting for compression, high-temperature shaft furnace retrofits, or hydrogen storage facilities. No amount of pilot success changes that. The economics are not projected to improve quickly enough to matter in the next two decades.

Steel is a commodity. Margins are tight. Producers will not overpay for green credibility if other paths exist. MOE, flash with CCS, and biomethane DRI all offer credible, scalable paths with better cost structures and lower infrastructure risk. They also align with Australia’s industrial geography. MOE fits where renewables dominate. Flash fits where gas and CCS align. Biomethane DRI fits where organic waste and carbon sinks overlap.

The smart approach is not to pick a single winner but to deploy the right technology in the right place. Australia has the resources, the land, and the geological advantages to support all three. What it needs now is a shift in industrial policy and investment focus. Moving away from the hydrogen-first mindset will open space for more cost-effective and regionally aligned solutions.

MOE should be fast-tracked where renewables are plentiful. Flash ironmaking should be deployed in gas-rich corridors with CCS readiness. Biomethane DRI should be incentivized near agricultural basins and industrial carbon sinks. Each process addresses a different slice of the market, and together they build a credible, affordable, and geographically coherent zero-carbon steel sector.

This is not about ideological preference for one technology over another. It is about aligning Australia’s physical, economic, and geological resources with steelmaking pathways that match those realities.

With global steel demand falling short of earlier forecasts, there is less room for inefficient experiments. Every new plant must be economically justifiable. Hydrogen DRI is not. MOE, flash, and biomethane are.

Australia’s opportunity lies in matching the right method to the right place, and in doing so, shaping a low-carbon steel future that is built on actual resources and real-world costs.