Australia’s biggest battery storage installation, the 300MW/450MWh Victorian Big Battery near Geelong, has been given the all clear to resume its commissioning process after regulators finalised their investigations into the fire that destroyed two Tesla Megapack battery units in late July.

Neoen, the owner of the Victorian Big Battery – as well as batteries at the Hornsdale Power Reserve and Bulgana Energy Hub – said energisation of the battery would resume on Wednesday, September 29, to try and make it ready for the Australian summer.

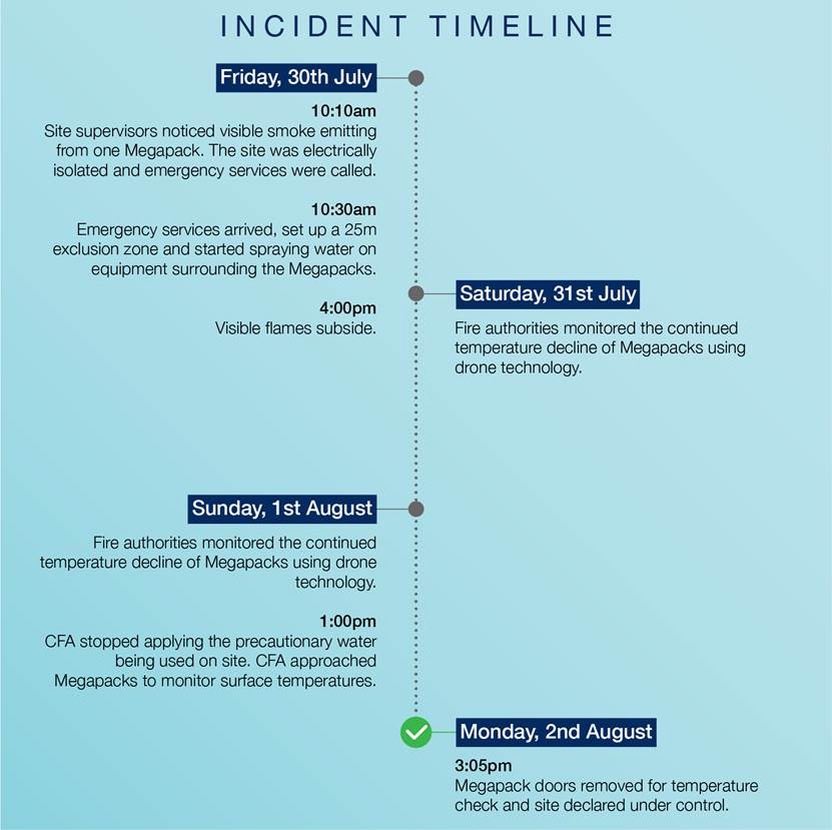

The dramatic fire occurred with days of the commencement of initial testing at the Victorian Big Battery, and brought the commissioning process to a halt, although installations of the remaining 212 Tesla Megapacks at the site continued.

Neoen says investigations – including from the Country Fire Authority, WorkSafe Victoria, Energy Safe Victoria, and the Environment Protection Authority, Tesla and Neoen – had helped identified the cause of the fire.

RenewEconomy understand that Tesla’s detailed testing of its Megapack units included setting fire to some units at a testing facility in Nevada to identify the root cause of the fire and any faults.

“The most likely root cause of the incident was a leak within the Megapack cooling system that caused a short circuit that led to a fire in an electronic component,” an Energy Safe statement said.

“This resulted in heating that led to a thermal runaway and fire in an adjacent battery compartment within one Megapack, which spread to an adjacent second Megapack.

Neoen said these events occurred while the Tesla Megapack was off-line in a service mode after being operating for 13 hours in the commissioning process. Going off line removed fault protections, and meant that the fault was able to go undetected, and it initiated a fire in the adjacent battery compartment.

It said mitigating actions had been put in place at the facility and across Tesla’s global Megapack fleet, including a combination of firmware enhancements, as well as monitoring and process improvements. SCADA testing of the battery had been reduced from 24 hours to one hour.

“Through these actions, Tesla has improved the detectability and associated fault protection against these types of rare events.”

The Victorian Big Battery is expected to play a key role in helping to manage the grid this coming summer, and has signed a 10-year agreement to provide services that will allow for an extra 250MW of peak capacity to be imported into Victoria at peak times on the main transmission links with NSW.

Neoen and Tesla say they are “continuing to work towards delivering the project in time” for the Australian summer.

“Safety is our first priority,” Neoen Australia managing director Louis de Sambucy said in a statement.

“We have taken the time to understand the cause of the incident and we have implemented actions to ensure it will not happen again. We would like to thank the Country Fire Association and the regulatory authorities for their thorough investigations.

“We are now actively working with all stakeholders to complete commissioning and testing of the project and we look forward to sharing the lessons learnt with the industry in coming weeks.”

Last week, Neoen was served with a federal court notice advising that the Australian Energy Regulator was seeking penalties against the Hornsdale battery in South Australia for allegedly failing to deliver contracted frequency control capacity in an event in October, 2019.

Neoen said that learnings from the Victorian Big Battery fire were being compiled by Energy Safety Response Group and Fisher Engineering, and the Independent Report would be shared publicly by November.

It says this will provide information and insights including lessons for fire management and emergency response to support the industry and relevant authorities in the deployment of battery storage technology.

In the meantime, the lessons learned and the actions introduced from the investigation to date, include:

- Each Megapack cooling system is to be fully functionally and pressure tested when installed on site and before it is put into service

- Each Megapack cooling system in its entirety is to be physically inspected for leaks after it has been functionally and pressure tested on site

- The SCADA system has been modified such that it now ‘maps’ in one hour and this is to be verified before power flow is enabled to ensure real-time data is available to operators

- A new ‘battery module isolation loss’ alarm has been added to the firmware; this modification also automatically removes the battery module from service until the alarm is investigated

- Changes have been made to the procedure for the usage of the key lock for Megapacks during commissioning and operation to ensure the telemetry system is operational

- The high voltage controller (HVC) that operates the pyrotechnic fuse remains in service when the key lock is isolated

Designers are also working to ensure that Megapacks are engineered to fully mitigate the risk of fire propagation from one unit to another under Victorian climatic conditions, with proposed mitigation procedures to be rolled out to applicable Megapacks globally.