SunDrive, a Sydney-based start-up that has been one of Australia’s big hopes in its efforts to deliver ultra-low cost solar PV technology, has cut staff and announced senior management changes as it gears up for its next phase of commercialisation.

The staff cuts, which have not been quantified, could affect up to half of the company’s staff numbers, and company co-founder and CEO Vince Allen will transition to the role of chief technology officer, allowing chief operating officer Natalie Malligan to become CEO.

SunDrive has been backed by some of Australia’s richest and most prominent people, including software billionaire Mike Cannon-Brookes, through his private investment fund Grok Ventures, former prime minister Malcolm Turnbull, Canva co-founder Cameron Adams, and others.

It is also one of the key players in the federal government’s hopes to produce “ultra low cost” solar in Australia by 2030, and to grab a significant slice of the global solar supply chain in its “Made in Australia” policy platform.

Renew Economy heard rumours late Monday that the company was getting ready to cut staff numbers by around 50 people, with an announcement due to be made to staff on Tuesday. Rumours swirled around the fate of its ground breaking technology that seeks to use cheaper copper rather than silver to cut the cost of solar PV modules.

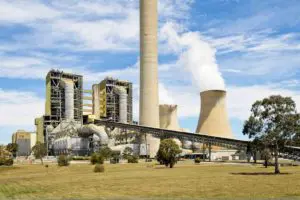

But the company denied that speculation on Tuesday, saying that its MoU with energy giant AGL to potentially build a solar manufacturing plant at the site of the shuttered Liddell coal plant in the Hunter Valley is still on track.

“We are committed to focussing on our core strengths of improving solar technology while continuing to pursue commercial partnerships to bring these technologies to market and accelerate the path to domestic manufacturing,” it said in a statement to Renew Economy.

“As part of the review, SunDrive has made the difficult decision to streamline its operations, resulting in some members of the team departing the business.

“SunDrive is supporting all affected employees through this process. This decision was not made lightly but we believe it is necessary to support SunDrive’s long-term success in continuing to deliver world-leading solar technology breakthroughs.”

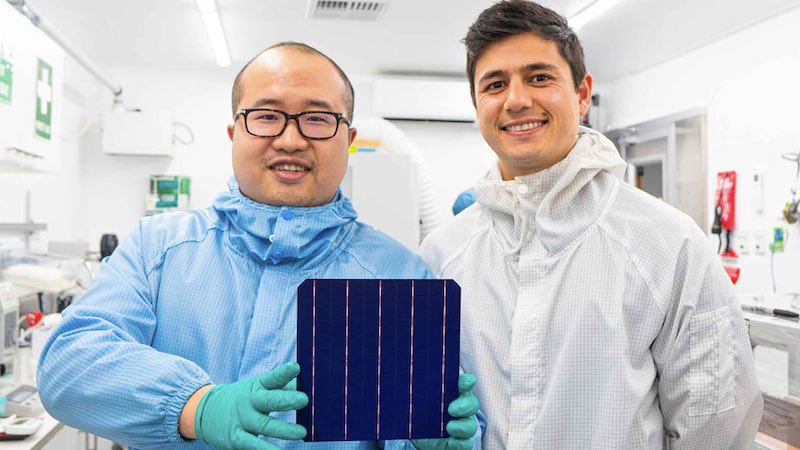

The company has been working on technology that would use copper rather than silver in the hope of cutting costs, and has been working on boosting the efficiency of that technology.

Solar companies have been looking for a copper solution for decades – because the price of copper is a fraction that of silver – but it is complex work, mostly because copper is a potential contaminant to the silicon used in solar photovoltaic technology. If contaminated, silicon based panels will cease to work effectively.

Its work has been highlighted by the Australian Renewable Energy Agency as one of the great hopes for the goal of “ultra low cost solar” – defined by ARENA as a 30-30-30 vision representing 30 per cent solar module efficiency and an installed cost of 30 cents per watt by 2030.

ARENA last November announced it would give $11 million in grant funding to SunDrive, to expand its novel solar cell metallisation technology from prototype scale (around 1.5 megawatts a year) to commercial capacity of more than 100 MW a year.

“SunDrive’s technology that replaces silver with copper is a potential game changer and highlights why now is the time to invest in technologies for our future economic success,” ARENA CEO Darren Miller said at the time.

Prime minister Anthony Albanese and climate and energy minister Chris Bowen officially opened SunDrive’s solar manufacturing pilot production and commercialisation facility in Kurnell, NSW, in November. (See photo above).

SunDrive said Allen’s shift to the CTO position would allow him to focus on the development of the company’s world-leading technology. It said Malligan had vast experience in scaling up start-up companies, including Uber, and has an MBA from the Columbia Business School.

“SunDrive remains committed to building on Australia’s long and proud history of solar innovation and contributing to the growth and success of the Australian solar industry.”

One SunDrive employee, Albert Chau, said on LinkedIn on Tuesday that he was finishing up as a mechanical engineer at SunDrive, prompting the response “yeah same” from Eric Trinh, also a mechanical engineer. Several others said they had been made redundant.

“It is with a heavy heart that I’m announcing my time at SunDrive is at an end,” Chau wrote. “This has been the most fun and interesting work I’ve had as an engineer in my career so far, and I am immensely proud of what my team and I have achieved.”

Another comment on Chau’s post, wishing him well, comes from Jonathan B., whose profile describes him as a Mechanical Design Engineer at Sundrive Solar who is “currently open to work.” Others said they had been made redundant.

SunDrive was established by CEO Vince Allen during his PhD at the University of New South Wales which looked at the use of copper for PV cell metallisation, instead of silver, a metals swap that could – in theory – result in an installed cost of solar that is 20-30% cheaper than other high-efficiency cells.

Sundrive has attracted funding from a range of deep pocketed investors, including Cannon-Brookes, Blackbird Ventures, Virescent Ventures, and the Clean Energy Finance Corporation.

In November 2020, SunDrive was awarded a $3 million Arena grant towards the production of a commercial-size PV module for use on household rooftops.. The second Arena grant in November 2023 awarded the company $11 million to scale up its solar cell production line to a commercial level.

As part of a flurry of activity in 2022-2023 – including a solar cell efficiency record – the company hired Wyatt Roy, the former Coalition MP and assistant innovation minister who was the youngest elected to parliament in 2010 when aged just 20, as its strategic advisor.

Roy announced SunDrive’s plans to build factories that could produce up to 5GW of solar PV a year, with the first factory to target the premium rooftop market with capacity of 1GW, and focus on “cell metallisation” and modules.

The second, lifting total capacity to 2GW, would focus on rooftop modules and introduce cell production, including texturing and junction cells.

A third factory, taking the total capacity to 5GW, would focus on the utility solar farm and would see the factory facilities scale up to become fully integrated, including poly silicon, ingot and wafe and glass production.

Roy departed from SunDrive not long after speaking to Renew Economy’s Solar Insiders podcast, for a role as head of innovation on the Kingdom of Saudi Arabia’s urban development project, Neom.