Engineers from RMIT University in Melbourne have invented a new device that is expected to offer a cheaper and more efficient method of seabed testing as part of designing offshore wind farms.

During the early design phase of an offshore wind farm project, probes known as penetrometers are winched or dropped to the seafloor to determine the suitability of the seabed for installing wind turbine foundations.

While this technique is beneficial for deeper waters, these lightweight freefall soil penetrometers probes are less effective in shallower waters where the seabed is sandier, while heavier-duty probes capable of penetrating the sandy seabed can cost up to $200,000 per day to operate.

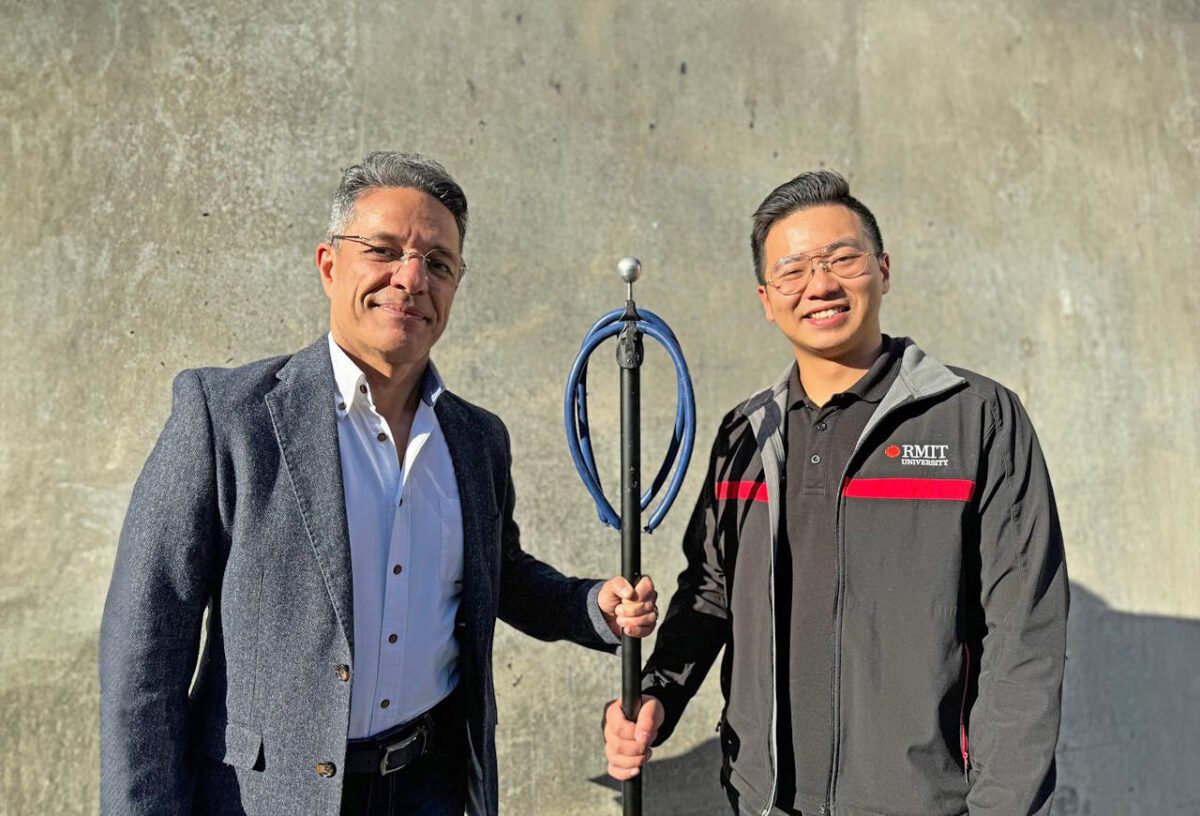

To address these issues, engineers from RMIT University and the University of Melbourne have designed a probe based on the design of a modified speargun that they say could be twice as effective in penetrating the seafloor.

“In laboratory environments, the device showed considerably greater penetration potential compared to free-falling probes on soil,” said Junlin Rong, RMIT PhD candidate and lead author of a study published in the Canadian Geotechnical Journal.

“Notably, in high-density sandy material, the penetration depth was twice that of previously reported values achieved by freely falling probes.

“This breakthrough technique has the potential to revolutionise site investigations for wind farm projects, offering significant time and cost savings while outperforming the embedment achieved by other dynamic penetrometers.”

The RMIT researchers have already tested their device with various probe tips in different sand mixes within a water tank, utilising an array of sensors and high-speed cameras to capture the results.

The probes can also be retrieved and reused after data collection, minimising disturbing the seabed, and can also be adapted to existing probes, allowing engineers to retrofit their current devices with minimal investment.

According to Rong, existing cone penetration will likely remain the dominant method for testing seabeds but hopes that their new launching system could reduce the number of tests needed, reducing overall costs.

“Now that our experiments have demonstrated the device’s ability to achieve considerable embedment depth in dense sand, we are keen to conduct field trials and collaborate with our potential industrial partners to further test its performance for offshore geotechnical engineering application,” said Majid Nazem, RMIT professor of geotechnical engineering.