The ageing of coal fired power stations is currently in the news with the likely shutdown on Liddell Power Station in 2022.

Industrial plants and utilities shutting due to old age is actually a bit unusual.  Most plants and equipment systems that aren’t subject to arduous or corrosive environments can typically have their operational life extended with relatively low levels of maintenance and capital money spent, relative to the cost of their replacement.

Most plants and equipment systems that aren’t subject to arduous or corrosive environments can typically have their operational life extended with relatively low levels of maintenance and capital money spent, relative to the cost of their replacement.

They are more commonly finally shut down due to competition from new and more efficient technologies then from old age. Most power station electrical generator and transmission systems would fall into this category.

What does not fall into this category is power plant steel components in high temperature steam and boiler systems. They can be subject to a dangerous ageing mechanism called “high temperature creep cracking.”

Manufactures of power stations rate the life of their plants at 20 years and the high temperature creep failure mechanism in steel pipework and pressure vessels is the reason for this rating.

Power station manufacturers would like us to replace power stations at 20 years, but this rarely occurs. This is because the engineer standards for assessing creep failure mechanisms are very conservative and focus on worst case scenarios.

It is also because there are Non-Destructive Testing (NDT) methods that can assess the level of creep deterioration in steam systems. The biggest limiting factor is the cost and the power plant outage length to carry out these NDT tests.

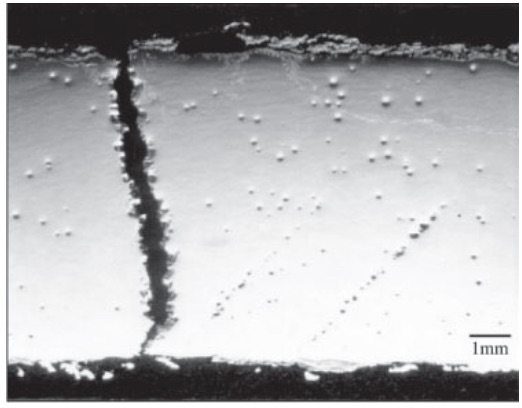

The most likely place for creep cracking to occur is in the highest operating temperature steel tubing inside a boiler. The image at right is a boiler tube that has been cut open to examine a creep crack failure.

This type of boiler tube failure can cause unexpected outages but these problems once identified can be manages without major safety risks. Liddell power station is now 45 years old and so is well over twice its rated age.

This means that the locations where creep cracking may lead to the possibility of failure is now much more extensive and so much more difficult and expensive to manage.

One of the worst-case failure scenarios for a power station steam system is a creep failure in one of the large main steam pipes within the turbine building of the power station.

It has been estimated that a main steam pipe rupture would fill a typical turbine building with high temperature steam in under 30 seconds. Anyone in the turbine building would be severely scalded and probably die.

This is not just an academic possibility as 21 people were killed and five injured in a high-pressure steam pipe failure at a Chinese power station in in the city of Dangyang in August of 2016 (Link). The ratio of killed to injured gives an indication of the horrific nature of such an accident.

The probability that this type of failure could occur in Liddell is very small, but it is possible. AGL, the owner of Liddell power station would be aware of these risks and it is likely one of the reasons they want to shut the station down.

Making full assessments of creep fatigue risks would be a huge and expensive exercise that would include scheduling shutdowns, building scaffolding, removing insulation and doing sophisticated NDT testing with lots of complicated prep work on kilometres of pipework.

It is very likely that some cracks and crack risk areas would be found and the required repairs would be very complicated and expensive. Add this to huge number of other problems that need to be repaired and managed in an aging plant, it is no wonder that AGL is keen to shut down Liddell.

Peter Todd is a reliability engineer and this was an article written for the quarterly publication Asset Reliability which he publishes.