On Thursday 2nd April, just prior to the Easter long weekend, I was fortunate to be able to attend an “Energy Express” seminar hosted by UQ Energy Initiative and the Global Change Institute – at which Professor Paul Meredith presented on the “Gatton Solar Research Facility”.

Though not as large as the Nyngan solar power station, which opened recently, this one is also opened recently to add to a pre-existing portfolio of solar facilities at UQ that have been developed to assist in meeting a number of coincident objectives, including:

1) To assist UQ achieve some ambitious carbon reduction targets;

2) To assist in energy procurement for the university; and

3) To provide facilities for “learning via doing” enabling various disciplines to work together in a systemic way in areas relevant to where society is headed for the future.

Professor Meredith covered a broad range of information during the talk, but one thing he noted stood out for me – and, I thought, would be of interest to some our readers as well.

The following is my recollection of these particular points so, if there are any mistakes or omissions, please blame my memory and not Prof Meredith (for the benefit of our other readers, feel free to point these out below).

At Gatton there are three different types of solar PV technology deployed (by First Solar, in this case):

Section 1) The bulk of the facility is “standard” fixed solar panels;

Section 2) There is a smaller share of the “off-the-shelf” single axis tracking system; and

Section 3) UQ has, in conjunction with its partners, installed a “first of its kind” dual axis tracking system to ensure optimal alignment of each panel in this section

With reference to the access provided here to the output data collected from the Gatton facility, I have copied in three static images that illustrate the particular point that caught my attention:

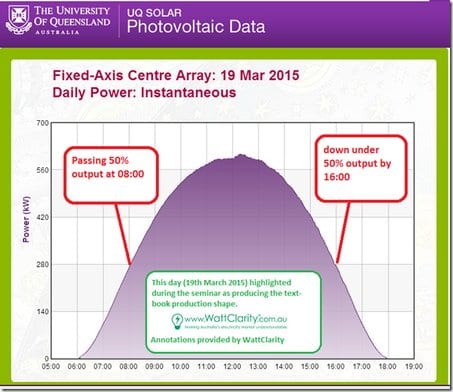

1) Production shape for the fixed-axis array

Prof Meredith highlighted 19th March 2015, which appears to be only 13 days after the plant came online, as the day where he’d seen the text-book production shape for the solar array:

Of the three banks of fixed-axis, I have selected the centre array.

2) Production shape for the single-axis tracking array

Next, Prof Meredith highlighted the different production profile apparent when looking at the single-axis array:

A “fatter” shape is clearly evident, which results from the ability of this array to change inclination to follow the sun’s path from east to west across the sky.

3) Production shape for the dual-axis tracking array.

Extending the process further, Prof Meredith explained how UQ and its partners had implemented a “first-of-its-kind” dual axis array with a tracking system designed to maximise the output of the array at any given point in the day.

The improvement in the shape here is not as marked (as from the 1st to the 2nd image above), but there does appear to be a higher capacity factor achieved.

Referring back to the title of this article “Benefits of tracking systems in solar PV” you will note no reference (until now) of the costs involved in their installation. My memory is a little vague here, but I think it was mentioned that the cost of the dual axis tracking array was something like three times the cost (per Watt installed) of the standard fixed-axis array.

As we’ve noted on WattClarity recently, demand in Queensland is peaking later and later in the day – including well after the 6pm sunset time implied in the charts above. Hence it does make it look difficult to achieve a commercially attractive payback on the fitting of tracking systems to increase the capacity factor beyond what’s possible with fixed axis arrays.

It does, however, show evidence of the potential network benefits of west-facing (e.g. residential) solar arrays – though, I would suspect, this might have the countervailing impact of reducing the capacity factor possible with the traditional north-facing inclination.

Perhaps those more knowledgeable in the solar space might like to help me understand better by adding comments below?

Source: Watt Clarity. Reproduced with permission.