Swedish car group Volvo is working on what it calls a “revolutionary concept” of developing lightweight energy storage components that could be incorporated into the body of a vehicle and greatly enhance the efficiency of electric vehicles.

Volvo has teamed up with nine other participants, including the EU and Imperial College London, to identify a feasible alternative to the heavyweight, large size and high costs associated with the batteries seen in hybrids and EVs today.

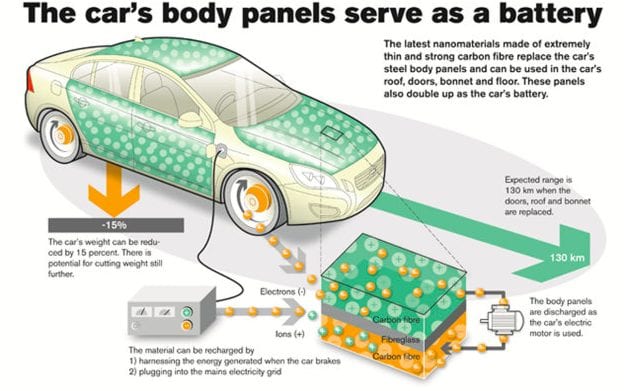

The solution – a battery system made from carbon fibres, polymer resin, nano-batteries and super capacitors – has been developed to act as body panels of the car as well as a fully functional battery.

The three and a half year research project has been tested on Volvo’s S80 model. The reinforced carbon fibres sandwich the new battery and are moulded and formed to fit around the car’s frame including the door panels, the boot lid, and the wheel bowl – saving large amount of space under the hood.

The fitted battery material is recharged and energised through brake energy generation or by plugging in to a main electrical grid.

Tests that have been run on the new car panels show that it is not only fully functional as a storage component, storing energy faster than conventional batteries, but also is a strong and pliant component of the car.

Volvo is hoping that this new material can replace the rally bar at the front of the car and the start-strop battery. These changes will see weight savings of more than 50 per cent and is powerful enough to supply energy to the S80 model’s 12 Volt system.

Overall, the components could cut the weight of an electric car by 15%, while increasing the efficiency of energy storage and improving the cost effective nature of the car.

This is its own assessment of the results so far:

“The boot lid is a functioning electrically powered storage component and has the potential to replace the standard batteries seen in today’s cars. It is lighter than a standard boot lid, saving on both volume and weight.

The new plenum demonstrates that it can also replace both the rally bar, a strong structural piece that stabilises the car in the front, and the start-stop battery. This saves more than 50% in weight and is powerful enough to supply energy to the car’s 12 Volt system.

It is believed that the complete substitution of an electric car’s existing components with the new material could cut the overall weight by more than 15%. This is not only cost effective but would also have improvements to the impact on the environment.”

The full list of participants include:

The full list of participants include:

- Imperial College London ICL United Kingdom (project leader)

- Swerea Sicomp AB, Sweden

- Volvo Car Group, Sweden

- Bundesanstalt für Materialforschung und-prüfung BAM, Germany

- ETC Battery and FuelCells, Sweden

- Inasco, Greece

- Chalmers (Swedish Hybrid Centre), Sweden

- Cytec Industries (prev UMECO/ACG), United Kingdom

- Nanocyl, NCYL