A new solar cell printer installed at CSIRO’s Melbourne labs is allowing scientists to produce Australia’s largest thin film solar cells, at 10 times their previous size.

Purchased over the last three months, the $200,000 printer has allowed researchers from the Victorian Organic Solar Cell Consortium (VICOSC) – a collaboration between CSIRO, the University of Melbourne, Monash University and industry partners – to print organic photovoltaic cells the size of an A3 sheet of paper.

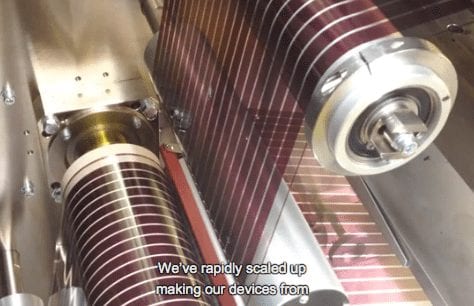

The consortium has developed processes that use spray coating, reverse gravure and slot-dye coating as well as screen printing – technology that has gone from producing solar cells the size of a fingernail to 10cm square in three years. The new printer means the VICOSC team have now made the jump to producing solar cells on sheets 30cm wide.

At this size, says CSIRO materials scientist Scott Watkins, Australia is definitely up there with the best in the world – and vastly increases the range applications the solar cells can be used for. “We can set them into advertising signage, powering lights and other interactive elements,” says Dr Watkins. “We can even embed them into laptop cases to provide backup power for the machine inside.”

“In the short term, we’re looking for applications in consumer devices and small integrated electronics. In the longer term, we see these materials being able to be coated onto buildings, into windows and on roofs to provide power in a wide variety of locations and circumstances,” Watkins says in the video posted below.

The organic PV cells, which produce 10–50 watts of power per square metre (although on smaller, lab-scale devices, power outputs equivalent to over 80W per square metre have been achieved) could also eventually be used to improve the efficiency of more traditional silicon solar panels.

“The different types of cells capture light from different parts of the solar spectrum. So rather than being competing technologies, they are actually very complementary,” says Dr Watkins.

“We need to be at the forefront of developing new technologies that match our solar endowment, stimulate our science and support local, high-tech manufacturing,” he says.

“While the consortium is focused on developing applications with current industrial partners there are opportunities to work with other companies through training programs or pilot-scale production trials.”

VICOSC project coordinator and University of Melbourne researcher David Jones says another of the advantages of the team’s approach to the technology is that they’re using existing printing techniques, making it a very accessible technology.

“We’re using the same techniques that you would use if you were screen printing an image on to a T-Shirt,” he says.

Using semiconducting inks, the researchers print the cells straight onto paper-thin flexible plastic or steel. With the ability to print at speeds of up to ten metres per minute, this means they can produce one cell every two seconds.

A complementary screen printing line is also being installed at nearby Monash University, making the Clayton Manufacturing and Materials Precinct one of the largest organic solar cell printing facilities in the world.

As for the cost of the technology, the ARENA-backed consortium is currently only purchasing materials on a research scale, but it anticipates that when buying on a larger scale, component costs will be significantly lower and pricing at around $1/W will be achievable.