The Queensland government has recruited two big name industrials to its newly established “virtual power plant”, a name it has given to a statewide network that sources electricity from large energy users to bolster supply during peak demand in the state’s north.

State energy minister Anthony Lynham said on Wednesday that zinc refiner Sun Metals and leading local agribusiness MSF Sugar had signed up as “foundation customers” of the scheme, which was first launched in Townsville in September last year.

Managed by Yurika – an arm of the publicly-owned utility Energy Queensland – the VPP uses the cloud-based energy management system of Melbourne-based company, GreenSync.

GreenSync’s peak response units, controlled by a staff of four in an office in Townsville’s CBD, work to remotely draw electricity from customers around the state to bolster supply during peak demand.

“The redistribution of power from this power plant helps to dampen out the peaks and falls of the wholesale power price, and it puts downward pressure on … power prices for every queensland family,” said Lynham in comments during the announcement.

“This is 150MW of power that we can tap into any time,” he added. “This is extremely significant and very cost effective. This is the way of the future for Queensland.”

Both Sun Metals and MSF Sugar have been active in developing their own renewable energy resources – MSF Sugar has built a bagasse-fuelled 24MW biorefinery as part of its operations in the Atherton Tablelands.

In a media statement on Wednesday, Minister Lynham welcomed the companies’ “vote of confidence” in the project, which he said had already proved its worth during the latest summer heatwaves.

“When demand spiked for those air-conditioners last week, the plant drew 44MW from a supplier in the south-east corner to help meet record peak demand,” Lynham said.

“Not only is this plant taking pressure off the network, it will help reduce the volatility of wholesale prices in the National Electricity Market – a major driver of power prices.

“This is another element of the Palaszczuk Government’s $2 billion Affordable Energy Plan that will make power bills more affordable, and our publicly-owned electricity system more reliable.”

As we have reported on RE, Sun Metals Zinc Refinery in Townsville is one of the largest consumers of energy in the state, leaving it at the mercy of rising wholesale power prices.

The construction of the solar farm – *which is being built south of Townsville by Australian solar PV contractor RCR, using First Solar modules – is expected to provide around one-third of the refinery’s electricity needs. The VPP allows the company to participate in the demand response side of the market, as well.

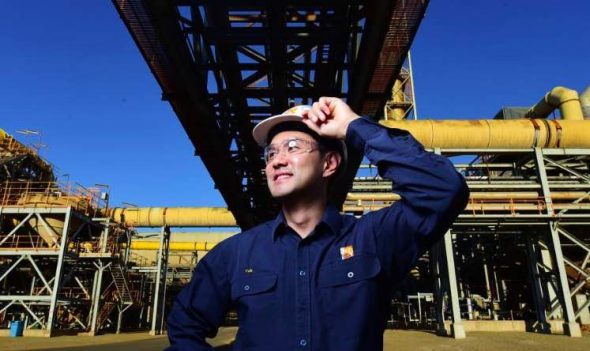

“The virtual power plant represents the future of energy and we are pleased to be a foundation customer,” said Sun Metals CEO Yun Choi.

“We can see the benefits for our business and the community.”

MSF Sugar’s general manager business development Hywel Cook said the program was an example of innovative businesses working together to achieve a better outcome for the future.

“Through the virtual power plant, we are working with Yurika to optimise our capacity for electricity generation and to better manage demand across our farms.

“While this will assist us in minimising costs, it will also assist with supply security across the energy network,” Cook said.

Yurika executive general manager Charles Rattray said the plant was already providing an immediate shot in the arm for Townsville with the extra staff and local contractors working on site inspection, hardware installation and asset maintenance.

*This article has been corrected to reflect that it is Australian solar contractor RCR that is developing the Sun Metals solar farm, and not First Solar. First Solar is supplying the PV modules for the project.