Sound waves could hold the key to producing hydrogen cheaper and more efficiently without a need for fossil fuels, Australian researchers say.

In the fight against climate change low-cost hydrogen made with renewable electricity is increasingly seen as useful for hard-to-abate industrial emissions sectors, including heavy equipment manufacturing.

The big question, however, is about costs. And engineering at Melbourne’s RMIT University say they have been able to boost production of green hydrogen 14-fold compared with standard techniques by deploying high frequency vibrations to “divide and conquer” individual water molecules during electrolysis.

Associate Professor Amgad Rezk, from RMIT’s School of Engineering, who led the work, says the team’s innovation tackles big challenges for green hydrogen production.

“One of the main challenges of electrolysis is the high cost of electrode materials used, such as platinum or iridium,” says Rezk.

“With sound waves making it much easier to extract hydrogen from water, it eliminates the need to use corrosive electrolytes and expensive electrodes such as platinum or iridium. As water is not a corrosive electrolyte, we can use much cheaper electrode materials such as silver.”

The ability to use low-cost electrode materials and avoiding the use of highly corrosive electrolytes are potential game-changers for lowering the costs of producing green hydrogen, according to Rezk.

The breakthrough offers a promising way to tap into a plentiful supply of cheap hydrogen fuel for transportation and other sectors, which could radically reduce carbon emissions and help fight climate change.

Green hydrogen is experiencing unprecedented momentum and given the current geopolitical turmoil leading to severe risks for global energy security, the need to accelerate its development has become even more important, according to the International Renewable Energy Agency.

Australian iron ore billionaire and Fortescue Futures Industries founder Andrew Forrest has set his sights on becoming one of the world’s leading producers of green hydrogen, with an improbable target of producing 15 million tonnes a year by 2030.

The RMIT research is published in Advanced Energy Materials, and a provisional patent application has been filed to protect the new technology.

A joint IRENA and the European Patent Office study reveals patent filings for hydrogen production technologies have grown on average by 18% each year since 2005.

The study’s findings showed that as far back as 2016, the number of patent families for water electrolysis technologies surpassed the number of patents related to producing hydrogen from fossil sources – namely solid or liquid coal and oil-based hydrogen sources.

Two years later, inventions for electrocatalysts based on cheaper minerals surpassed the number of those based on more traditional but expensive electrocatalysts, which use gold, silver, platinum or other noble metals, confirming the drive for cheaper alternatives.

The Australian technology shows the sound waves also prevented the build-up of hydrogen and oxygen bubbles on the electrodes, which greatly improved its conductivity and stability.

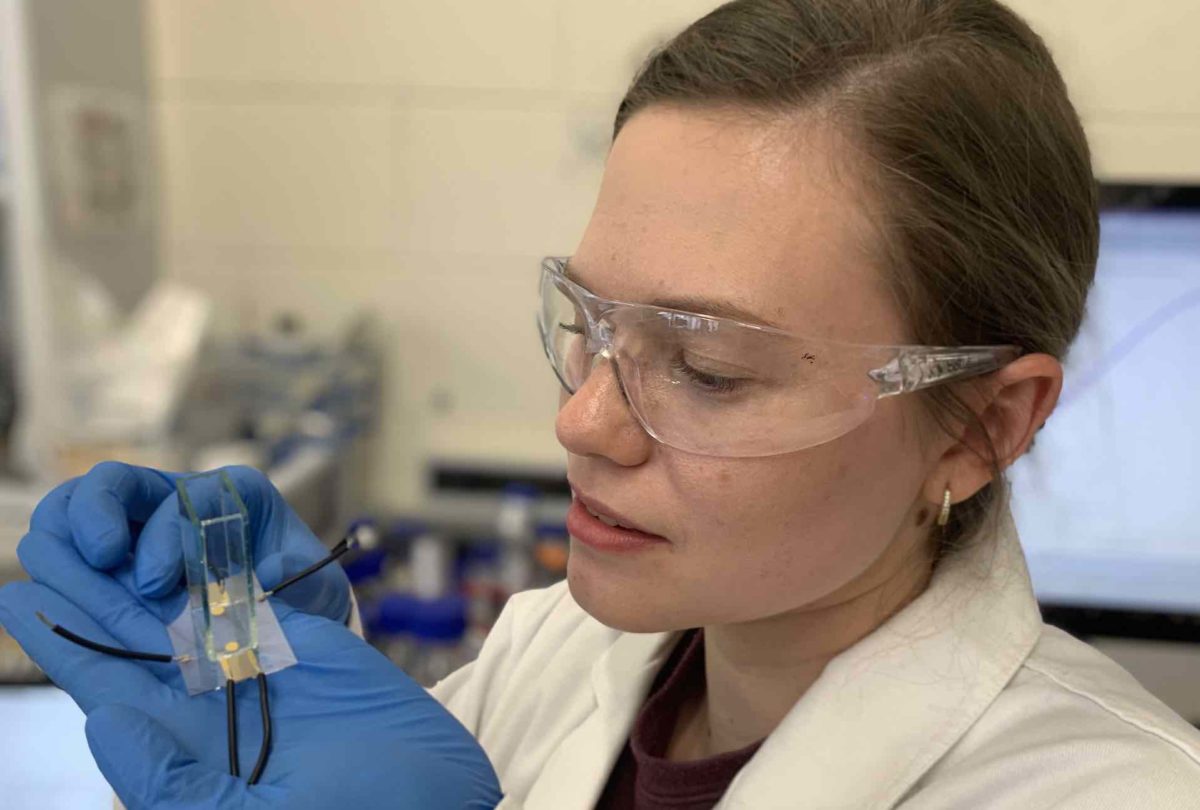

“Electrode materials used in electrolysis suffer from hydrogen and oxygen gas build-up, forming a gas layer that minimises the electrodes’ activity and significantly reduces its performance,” said first author Yemima Ehrnst, a PhD researcher at RMIT’s School of Engineering.

As part of their experiments the team measured the amount of hydrogen produced through electrolysis with and without sound waves from the electrical output.

“The electrical output of the electrolysis with sound waves was about 14 times greater than electrolysis without them, for a given input voltage. This was equivalent to the amount of hydrogen produced,” Ehrnst said.

While the innovation is promising, researchers acknowledged they still need to overcome challenges with integrating the sound-wave innovation with existing electrolysers to scale up the work